A gas heating water heater automatic water injection and automatic drainage system

A technology of automatic drainage and gas heating, applied in fluid heaters, lighting and heating equipment, etc., which can solve the problems of unit shutdown, frequent water injection operations, and freezing damage of the unit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

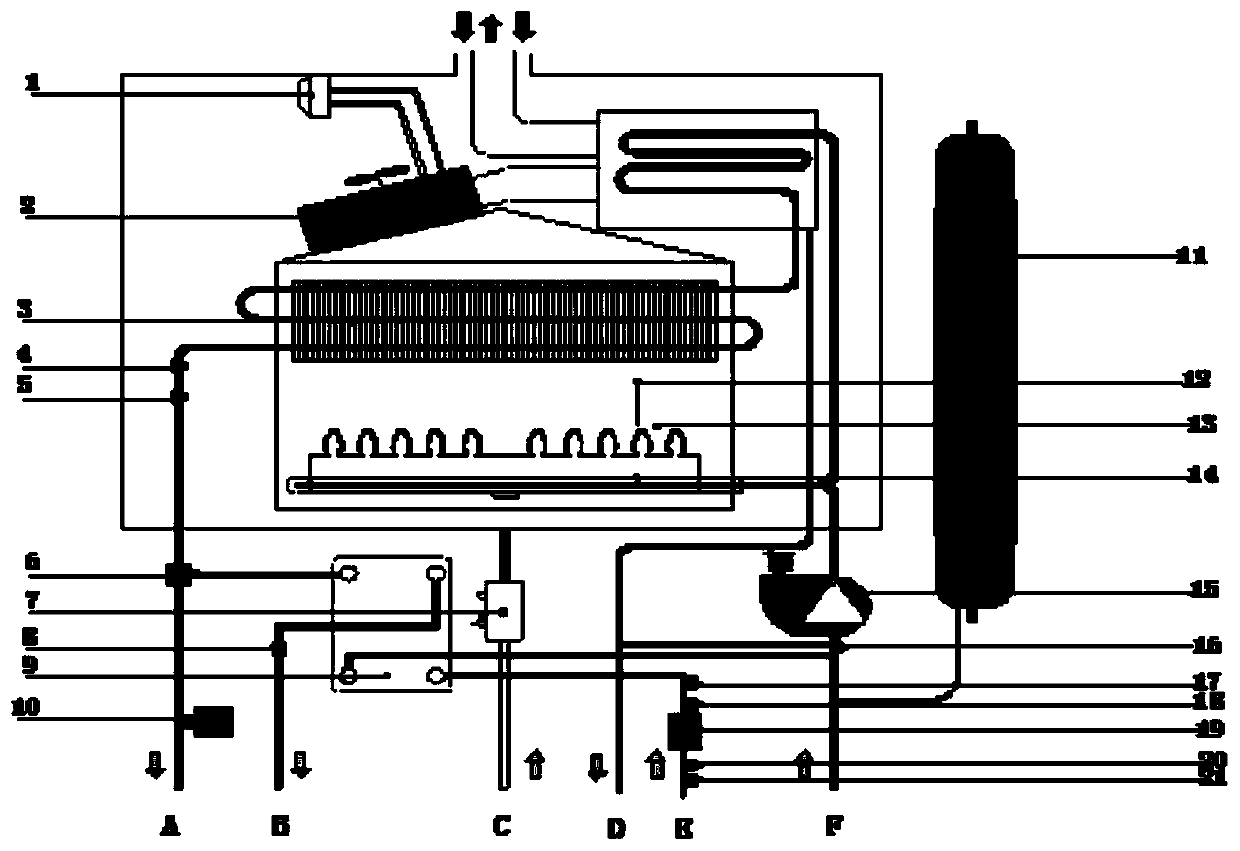

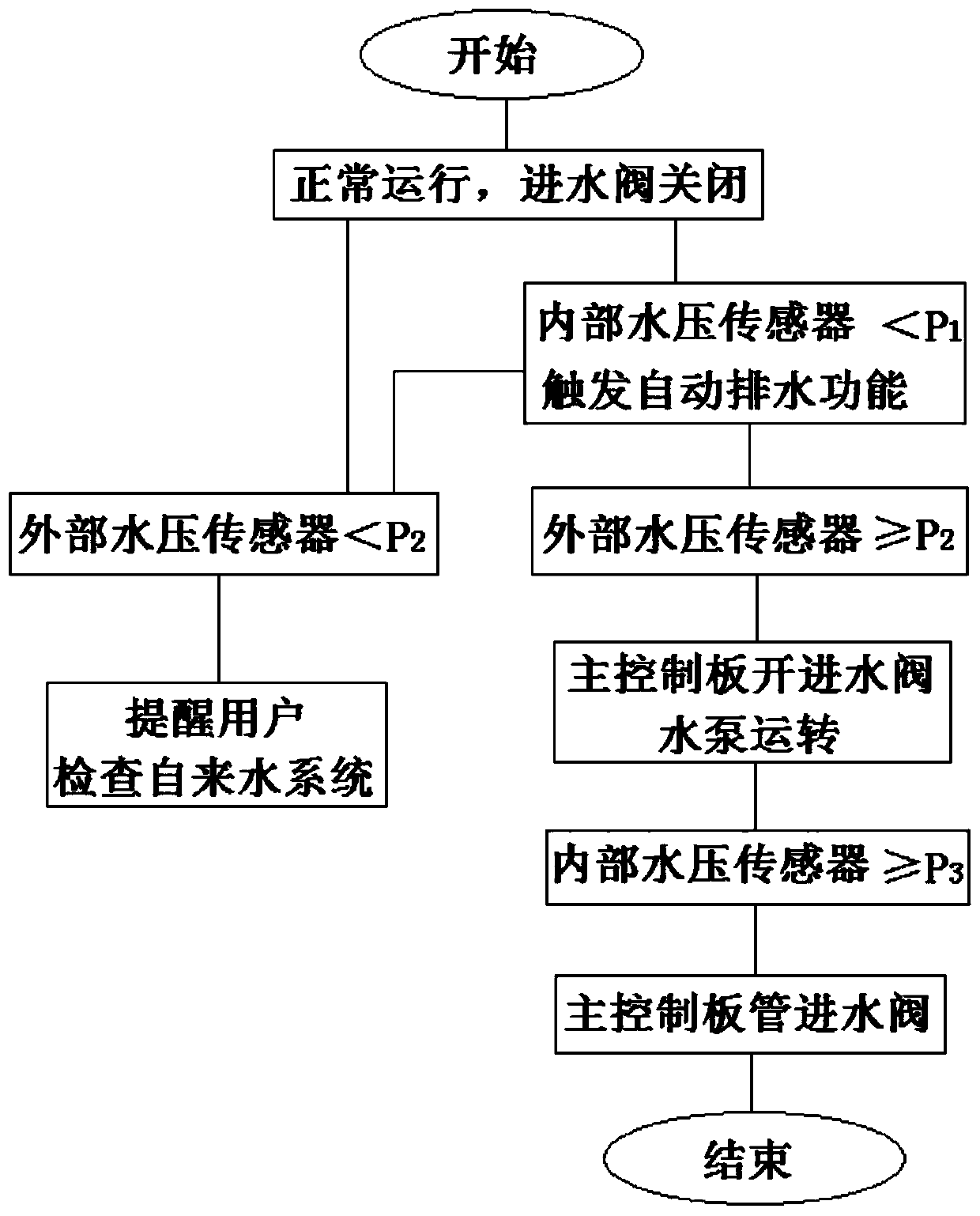

[0042] The automatic water injection system and the automatic drainage system of the gas heating water heater in this embodiment are installed on the basis of the dual-purpose heating water heater. The principle and structure of the dual-purpose heating water heater in this embodiment are as follows: figure 1 shown.

[0043]The gas heating water heater includes a main heat exchanger 3 , a burner 14 , a fan 2 , a plate heat exchanger 9 , and a water pump 15 . A wind pressure switch 1 is installed on the fan 2, and a flue gas waste heat recovery condenser is arranged at the rear end of the fan. The burner 14 is provided with an ignition needle 12 and a fire detection needle 13, and the burner 14 is connected to the gas inlet C through the gas proportional valve 7. The downstream of the main heat exchanger 3 is connected to the heating pipeline leading to the heating outlet A, and the heating pipeline is provided with a safety temperature limiter 4 , a heating outlet temperatur...

Embodiment 2

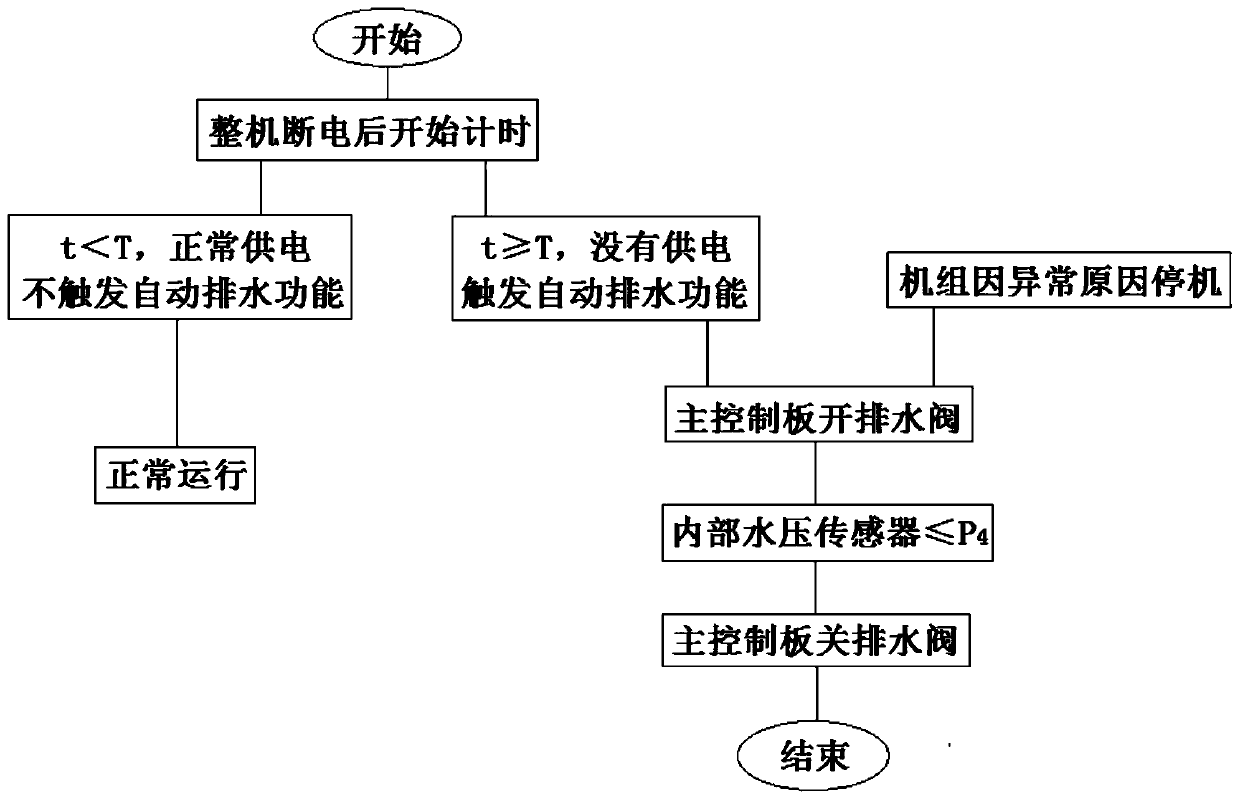

[0067] The difference between the gas-fired heating water heater, the automatic water injection system and the automatic drainage system in this embodiment lies in the structure of the automatic drainage system.

[0068] The drain valve in the automatic drainage system is a mechanically responsive drain valve, which automatically drains water as long as the water pump stops, but also drains the heating system when it is in standby.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com