A fuel tank for rapid cook-off of wind-resistant ammunition

A fuel tank and fast technology, applied in the direction of ammunition, ammunition test, attack equipment, etc., can solve the problems of heavy oil pool, difficult to operate, easy to escape from the oil pool, and large depth of the oil pool, so as to save fuel for testing and test. Convenience, fuel consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

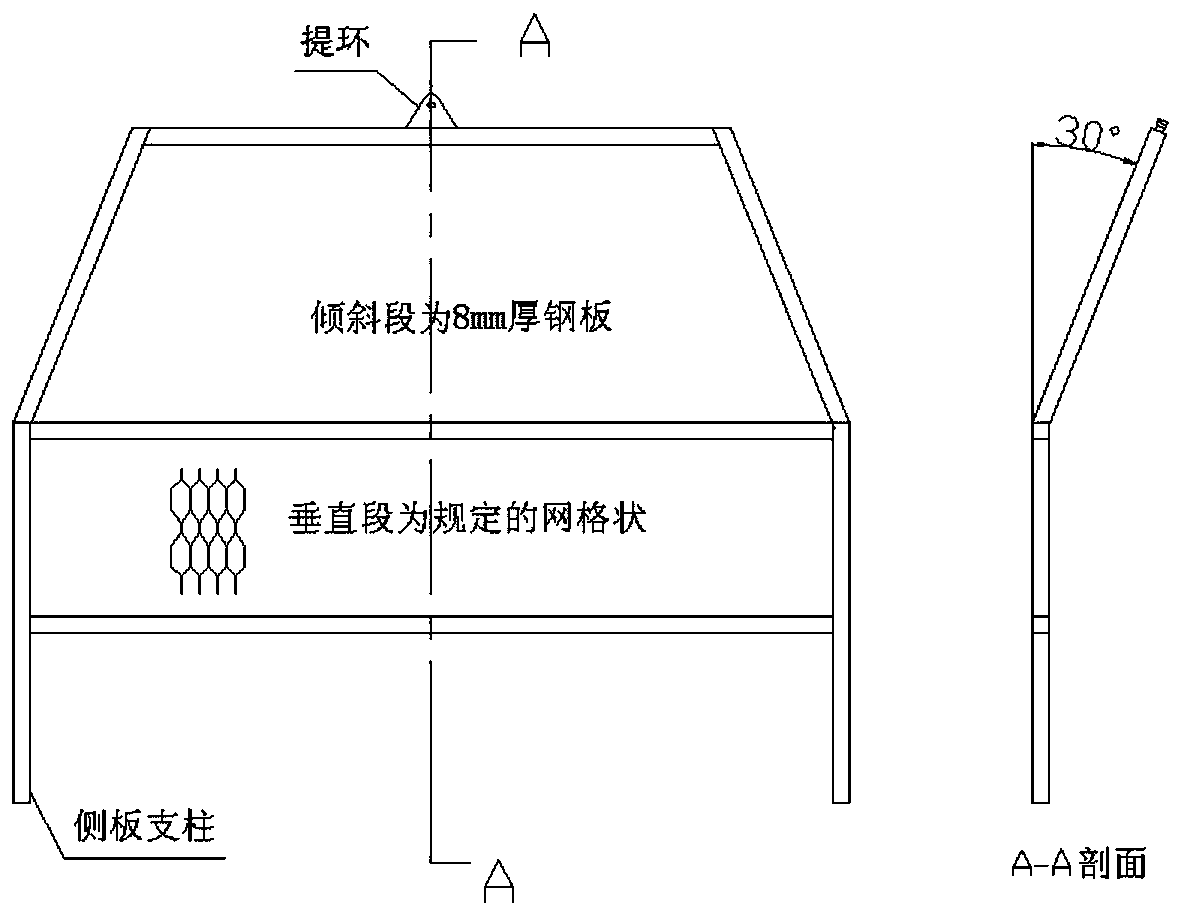

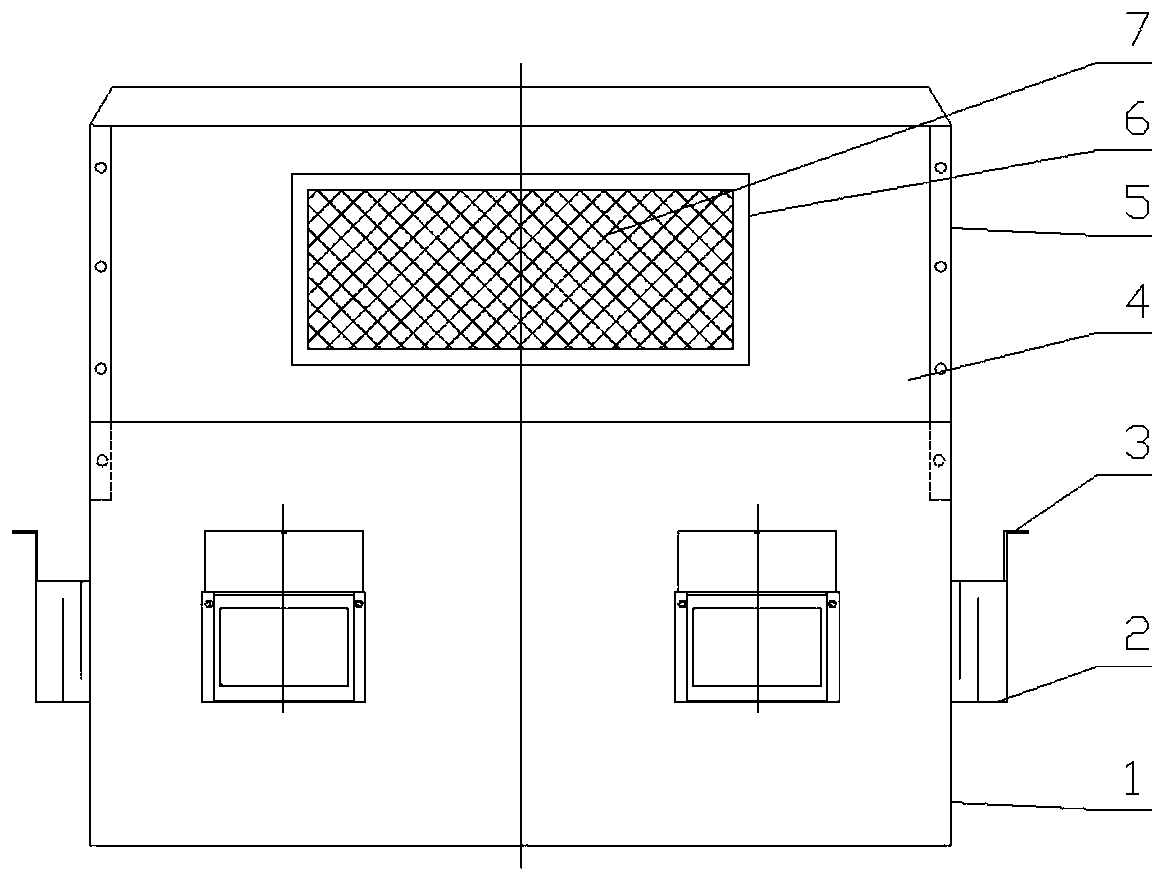

[0028] The present invention refers to figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 implement.

[0029] 1.1 Manufacture of the present invention

[0030] The component materials used in the present invention are made of 45# steel or Q235 steel when not specified, and the surface is treated with anticorrosion.

[0031]The oil pool 1 of the present invention is a flat-bottomed square groove without a top cover made by a 1mm-5mm thick steel plate, and two rectangular holes with a width of 50mm-170mm and a length of 70mm-180mm are respectively opened on the four walls. The liquid level of the liquid fuel is determined, the center line of the long side of the rectangular hole coincides with the length trisector of the tank wall, and at least one via hole with a diameter of 4mm-10mm is opened at each of the four corners near the upper edge of the notch;

[0032] The air duct 2 of the present invention is a cubic box made of 1mm-5mm thick steel plates w...

Embodiment 2

[0044] The present invention refers to the attached image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 implement.

[0045] 2.1 Manufacture of the present invention

[0046] The manufacturing method of the present invention is basically the same as that of Embodiment 1, the difference is that the windshields 4 are connected by a connecting piece 5, and the windshields 4 and the oil pool 1 are connected by a connecting block 51:

[0047] The oil pool 1 of the present invention is basically the same as that of Embodiment 1, except that no via holes with a diameter of 4mm-10mm are opened near the upper edge of the notch at the four corners, and each side wall of the oil pool 1 is respectively opened near the upper edge. Two via holes with a diameter of 4mm-10mm, the position of the hole is consistent with the center position of the two rectangular holes on each side wall;

[0048] Air channel 2 of the present invention is identical with embodiment 1;

[0...

Embodiment 3

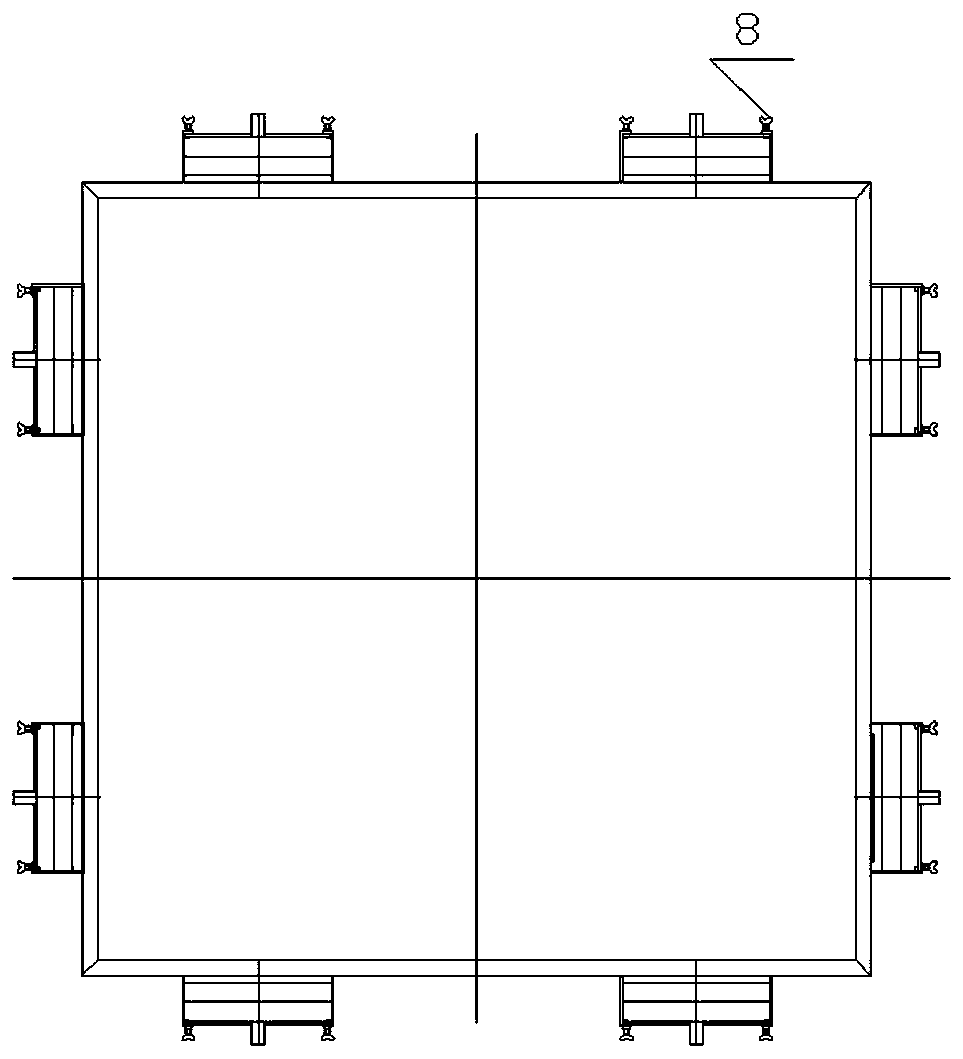

[0060] The present invention refers to the attached image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 9 implement.

[0061] 3.1 Manufacture of the present invention

[0062] The manufacturing method of the present invention is basically the same as that of Embodiment 1, except that the air duct 2 is composed of a net plate 61 and a bead 71:

[0063] Oil pool 1 of the present invention is identical with embodiment 1;

[0064] The stencil 61 of the present invention is a sieve plate made of 1mm-2mm steel wire, the mesh is diamond-shaped, and the diameter of the inscribed circle is 2mm-10mm. The stencil is made 10mm larger than the rectangular holes on the side wall of the oil pool 1. -20mm rectangle;

[0065] Layering bar 71 of the present invention is that 2mm-5mm thick steel plate is made the steel bar of wide 8mm-15mm;

[0066] 3.2 Assembly of the present invention

[0067] The assembly of the present invention is basically the same as that of Embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Hem width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com