Device and method capable of determining real-time consolidation penetration parameters of tailing sands

A technology for permeability parameters and tailings sand, which is used in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc. It can solve large errors and cannot reflect the dynamic change process and characteristics of tailings sand permeability. , the change of pore water pressure and the change of soil density cannot be well reflected, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

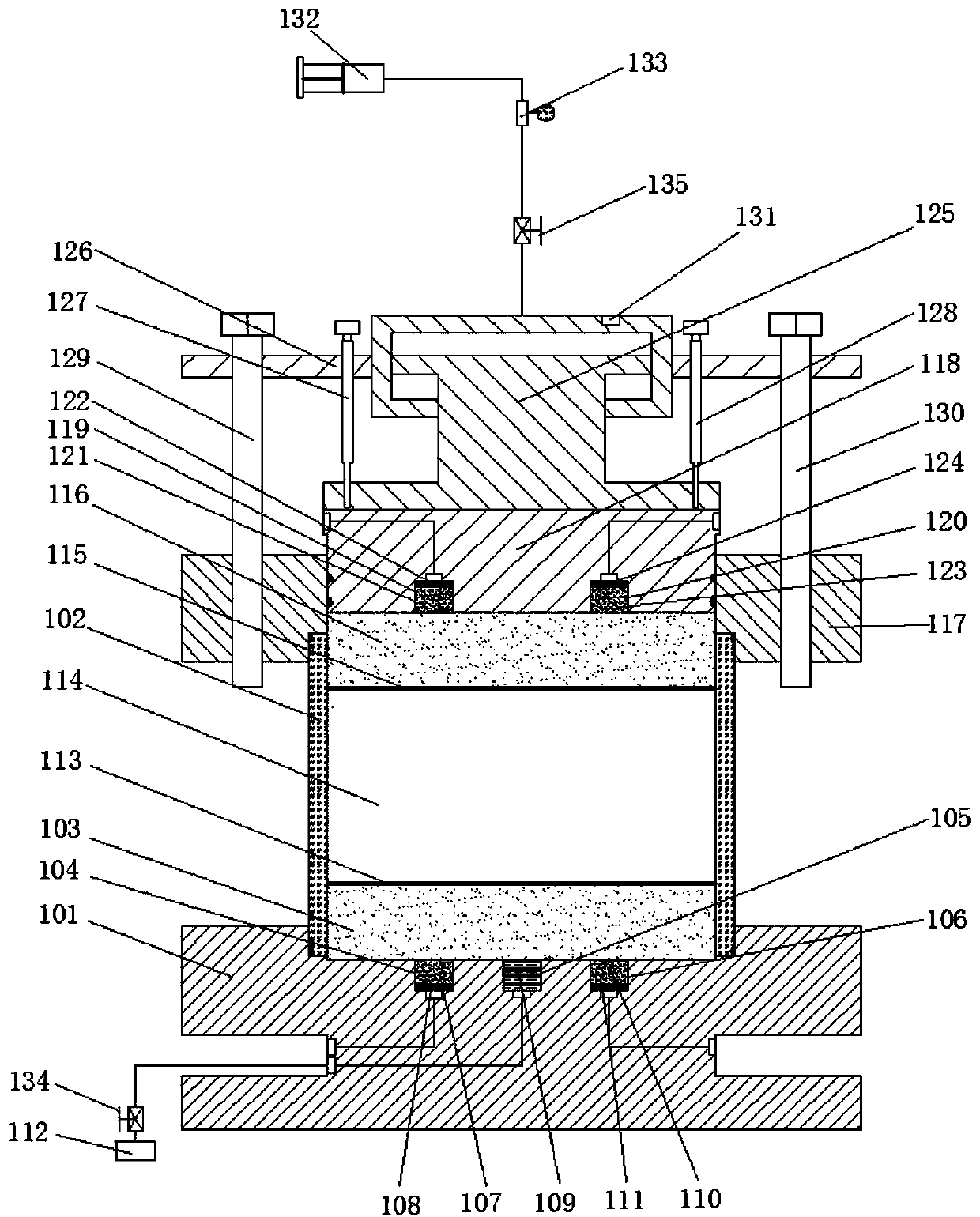

[0048] The method in this embodiment is applicable to the measurement of real-time permeability of soil samples during the consolidation process of coarse tailings.

[0049] A method capable of measuring real-time consolidation and penetration parameters of coarse-grained tailings sand adopts a device capable of measuring real-time consolidation and penetration parameters of tailings sand, comprising the following steps,

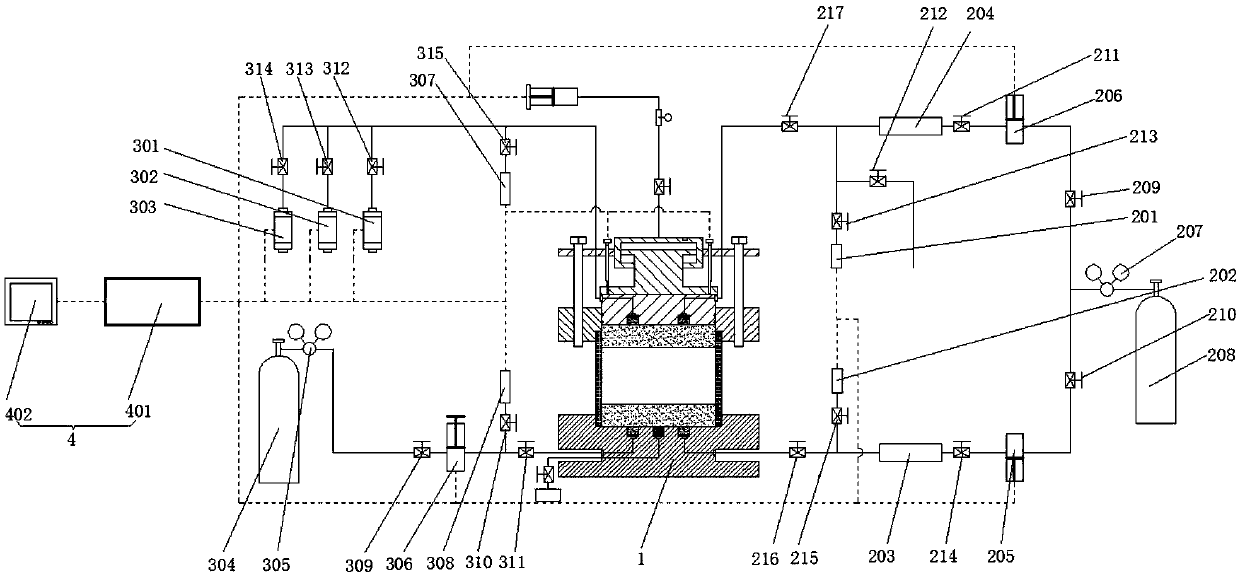

[0050]Step 1, close all valves before the start of the test, connect the soil sample consolidation system 1 without soil samples, the real-time permeability measurement system by the pressure pulse method, the real-time permeability measurement system by the flow method and the data acquisition and processing system 4, After connecting, check the leak of the whole system. First, open the No. 6 valve 309, No. 7 valve 311, No. 10 valve 217, No. 12 valve 216, No. 15 valve 211 and No. 16 valve 214, and then turn on the pressurized air pump at the left end 306. T...

Embodiment 2

[0059] The method in this embodiment is applicable to the measurement of real-time permeability of soil samples during the consolidation process of fine tailings sand.

[0060] A method capable of measuring real-time consolidation and infiltration parameters of fine-grained tailings sand, using a device capable of measuring real-time consolidation and infiltration parameters of tailings sands, comprising the following steps,

[0061] Step 1, close all valves before the start of the test, connect the soil sample consolidation system 1 without soil samples, the real-time permeability measurement system by the pressure pulse method, the real-time permeability measurement system by the flow method and the data acquisition and processing system 4, After connecting, check the leak of the whole system. First, open the No. 6 valve 309, No. 7 valve 311, No. 10 valve 217, No. 12 valve 216, No. 15 valve 211 and No. 16 valve 214, and then turn on the pressurized air pump at the left end 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com