Surface defect detection method and device based on machine learning

A defect detection and machine learning technology, applied in the computer field, can solve problems such as inaccurate detection results, and achieve the effect of solving inaccurate detection results and accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

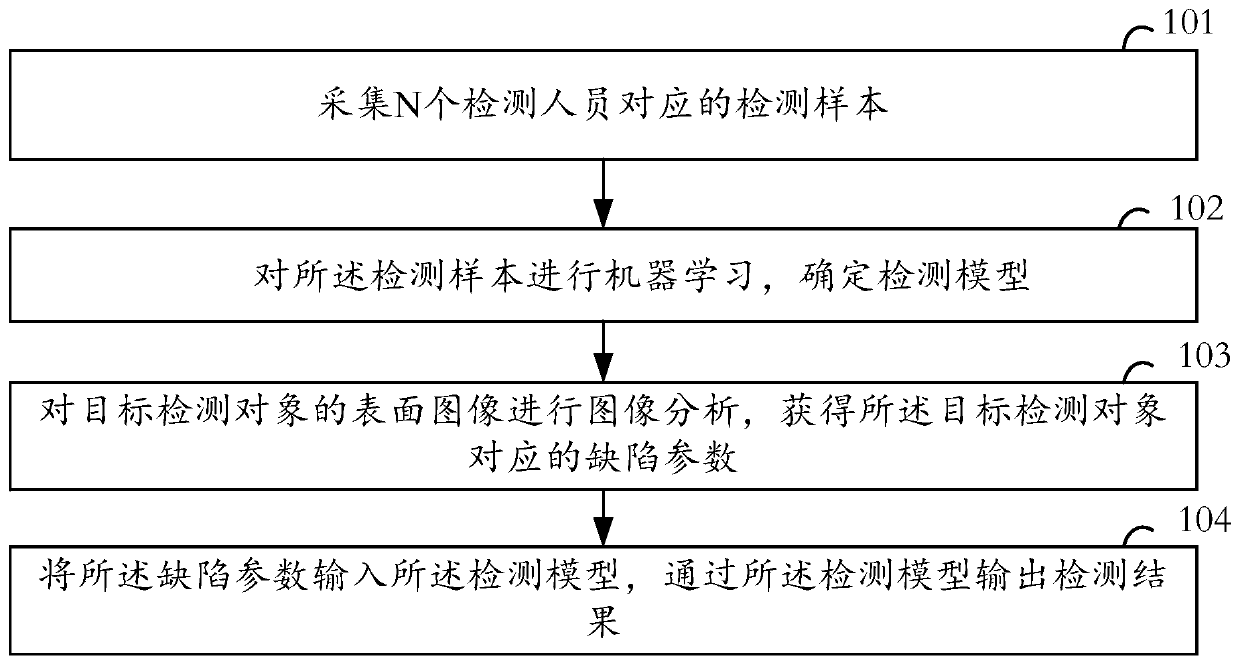

[0060] The surface defect detection method in this embodiment includes such as figure 1 Steps shown:

[0061] Step 101: Collect testing samples corresponding to N testing personnel, the testing samples include P defect parameters corresponding to the P historical testing objects one-to-one when the corresponding testing personnel determine that there are no surface defects in the P historical testing objects, And when the corresponding inspector determines that there are surface defects in the Q historical inspection objects, there are Q defect parameters corresponding to the Q historical inspection objects one-to-one.

[0062] Specifically, in this embodiment, test samples corresponding to N quality inspection testers can be collected, the value of N can be configured according to actual needs, and N testers can also be specified in advance, for example: N is 3, and Among the multiple quality inspectors, the historical test results corresponding to the three inspectors A, B,...

Embodiment 2

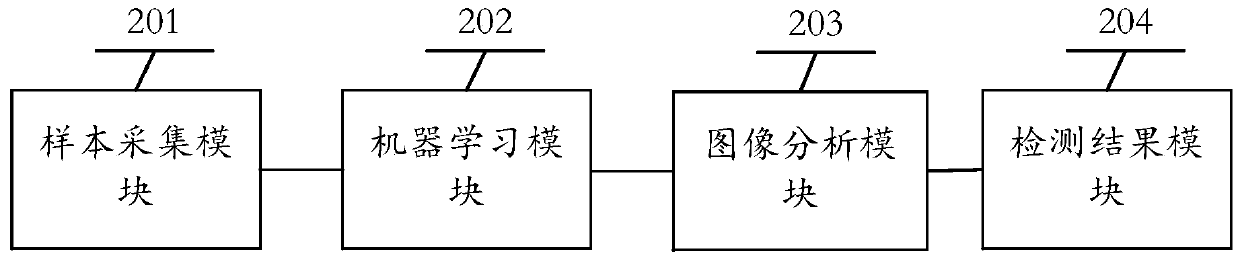

[0105] Please refer to figure 2 , based on the same inventive concept as the surface defect detection method in Embodiment 1, a surface defect detection device is provided in this embodiment, including:

[0106] The sample collection module 201 is used to collect test samples corresponding to N test personnel, and the test samples include the P values corresponding to the P historical test objects when the corresponding test personnel determine that there are no surface defects in the P historical test objects. defect parameters, and Q defect parameters corresponding to the Q historical detection objects one-to-one when the corresponding inspector determines that there are surface defects in the Q historical detection objects;

[0107] A machine learning module 202, configured to perform machine learning on the detection samples to determine a detection model;

[0108] The image analysis module 203 is configured to perform image analysis on the surface image of the target ...

Embodiment 3

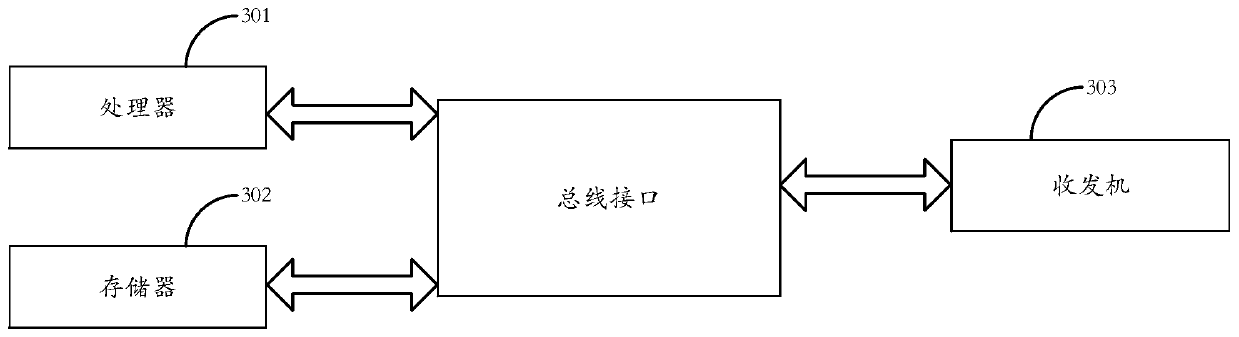

[0122] Based on the same inventive concept, this embodiment provides a device. For the specific implementation of the device, please refer to the description of the first embodiment, and the repeated parts will not be repeated, as image 3 As shown, the device mainly includes a processor 301, a memory 302 and a transceiver 303, wherein the transceiver 303 receives and sends data under the control of the processor 301, and the memory 302 stores a preset program, and the processor 301 reads The program in memory 302 executes the following process according to the program:

[0123] The processor 301 collects testing samples corresponding to N testing personnel, and the testing samples include P defect parameters corresponding to the P historical testing objects one-to-one when the corresponding testing personnel determine that there are no surface defects in the P historical testing objects, And when the corresponding inspectors determine that there are surface defects in the Q h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com