A high oxygen transport fuel cell catalytic layer and a membrane electrode assembly and a fuel cell

A membrane electrode assembly and fuel cell technology, applied in the direction of fuel cells, battery electrodes, electrical components, etc., can solve the problems of being unsuitable for the commercial application of fuel cells and cumbersome preparation process, and achieve commercial application, simple preparation method, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

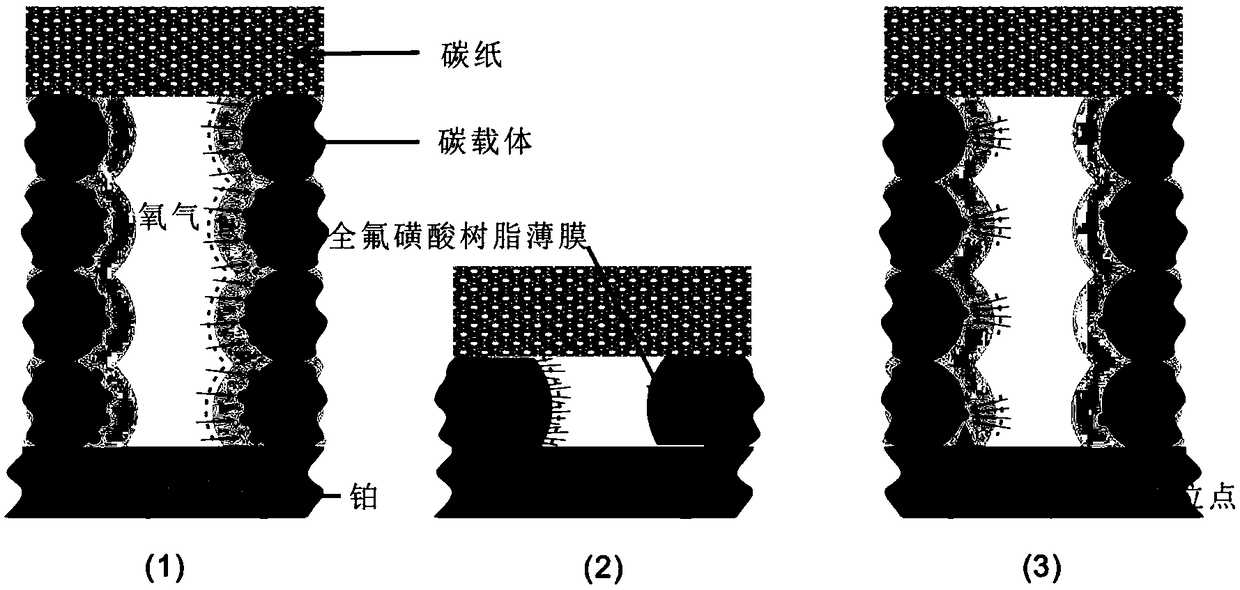

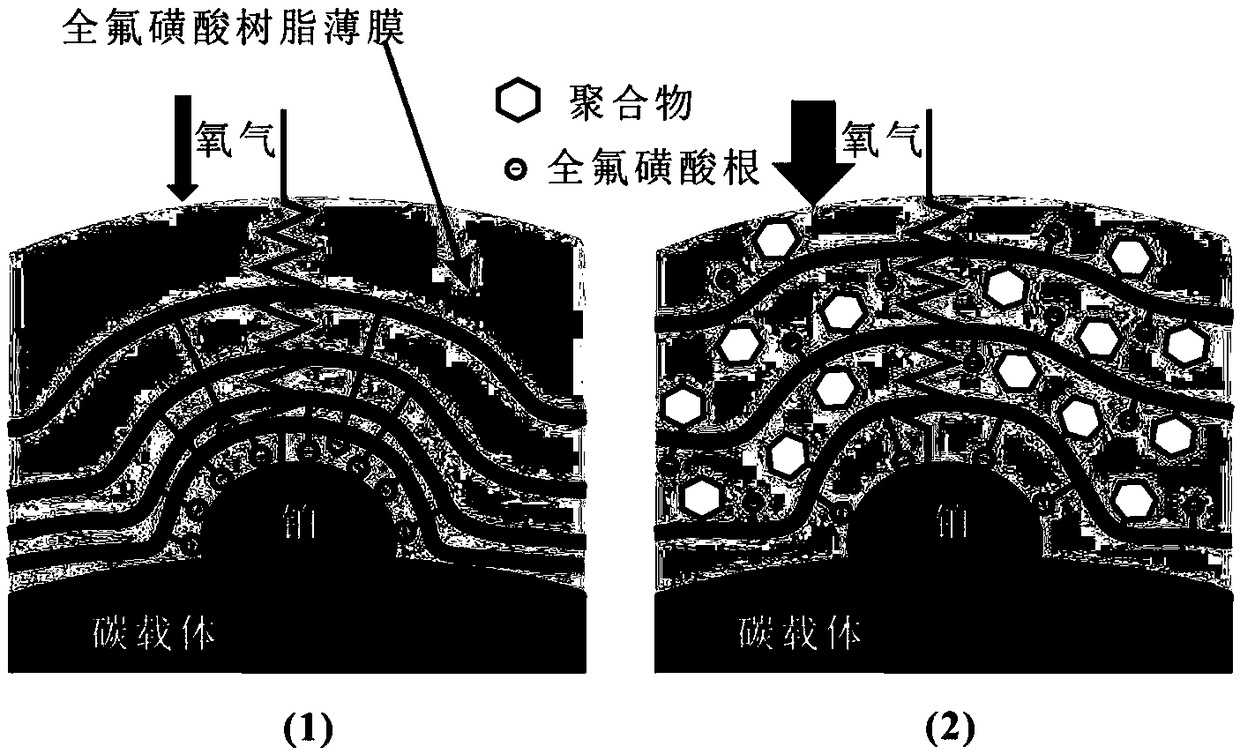

[0030] The present embodiment provides a high oxygen transport fuel cell catalytic layer, the high oxygen transport fuel cell catalytic layer comprises carbon-supported Pt particles and a polymer film on the surface of the Pt particle, the polymer film is perfluorosulfonic acid resin and cationic polymerization bound membranes (such as figure 2 (2) in). figure 2 (1) in means that there is no cationic polymer.

[0031] This embodiment also provides a method for preparing the catalytic layer of the high oxygen transport fuel cell, comprising the following steps:

[0032] 1) Prepare the mixed solution of cationic polymer polydiallyl dimethyl ammonium chloride (PDDA) solution and perfluorosulfonic acid resin, wherein the mole of sulfonate radical in cationic polymer and perfluorosulfonic acid resin The ratio is 1:30;

[0033] The specific configuration method of the above mixed solution is as follows: the mixed solution is prepared according to the mass ratio of PDDA solution...

Embodiment 2

[0041] This example is roughly the same as Example 1, except that the molar ratio of the positive ions in the cationic polymer to the sulfonate groups in the perfluorosulfonic acid resin is 1:60. Test results such as Figure 5 and Image 6 shown.

Embodiment 3

[0043] This example is roughly the same as Example 1, except that the molar ratio of the positive ions in the cationic polymer to the sulfonate groups in the perfluorosulfonic acid resin is 1:90. Test results such as Figure 5 and Image 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com