Preparation apparatus of fiber reactive dye

A technology for reactive dyes and preparation devices, which is applied in transportation and packaging, mixers with rotating containers, dissolution, etc., can solve the problems of no protective dustproof device, uneven stirring, large power consumption, etc. High mobility, accelerated stirring effect, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

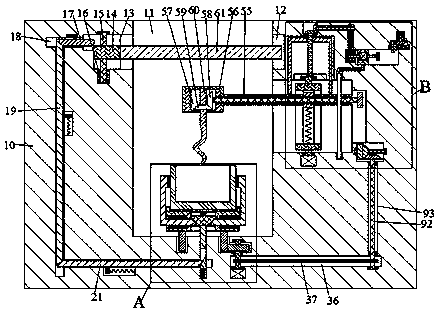

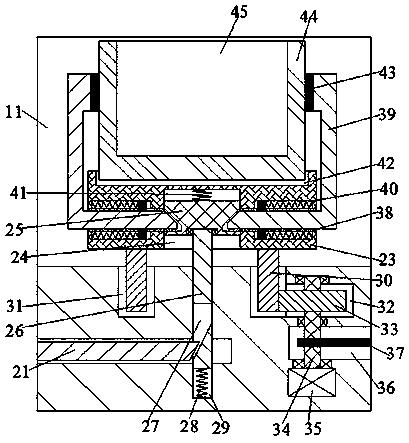

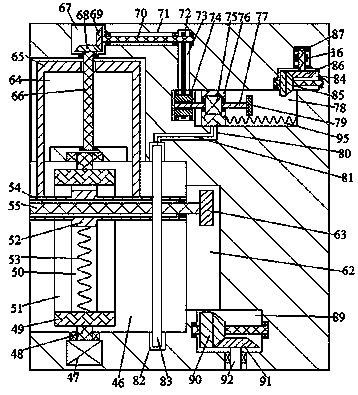

[0011] Combine below Figure 1-3 The present invention will be described in detail.

[0012] refer to Figure 1-3 , according to an embodiment of the present invention, a preparation device for a fiber-reactive dye includes a body 10, a cavity 11 with an opening facing upward is provided in the body 10, and the cavity 11 is symmetrically connected with an opening facing inward And the annular groove 12 that the rear side communicates with the outside world is provided with a closed cover 61 in the annular groove 12, and the left side of the annular groove 12 on the left side communicates with a lifting and rotating cavity 13 with an opening facing the right, and the closed cover 61 The left end extends into the lifting rotary cavity 13 and is fixedly provided with a lifting rotary block 14, and the upper end of the lifting rotary block 14 is fixedly provided with a first rotating shaft 15 that is rotatably connected to the upper end wall of the lifting rotary cavity 13. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com