Environment-friendly automatic drilling device

A drilling device, an environment-friendly technology, applied in the field of environment-friendly automatic drilling devices, can solve problems such as physical exertion, environmental pollution, and a large amount of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

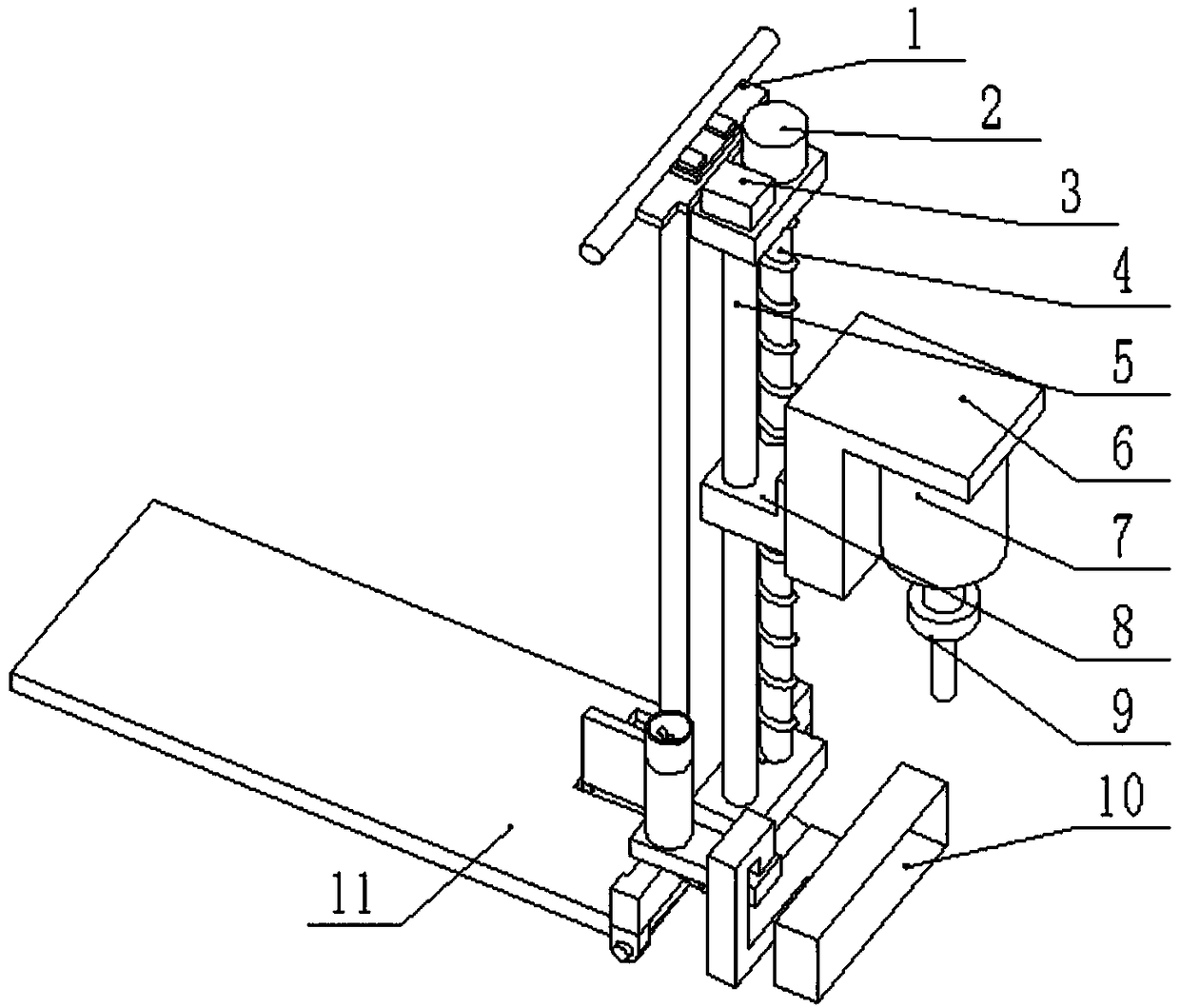

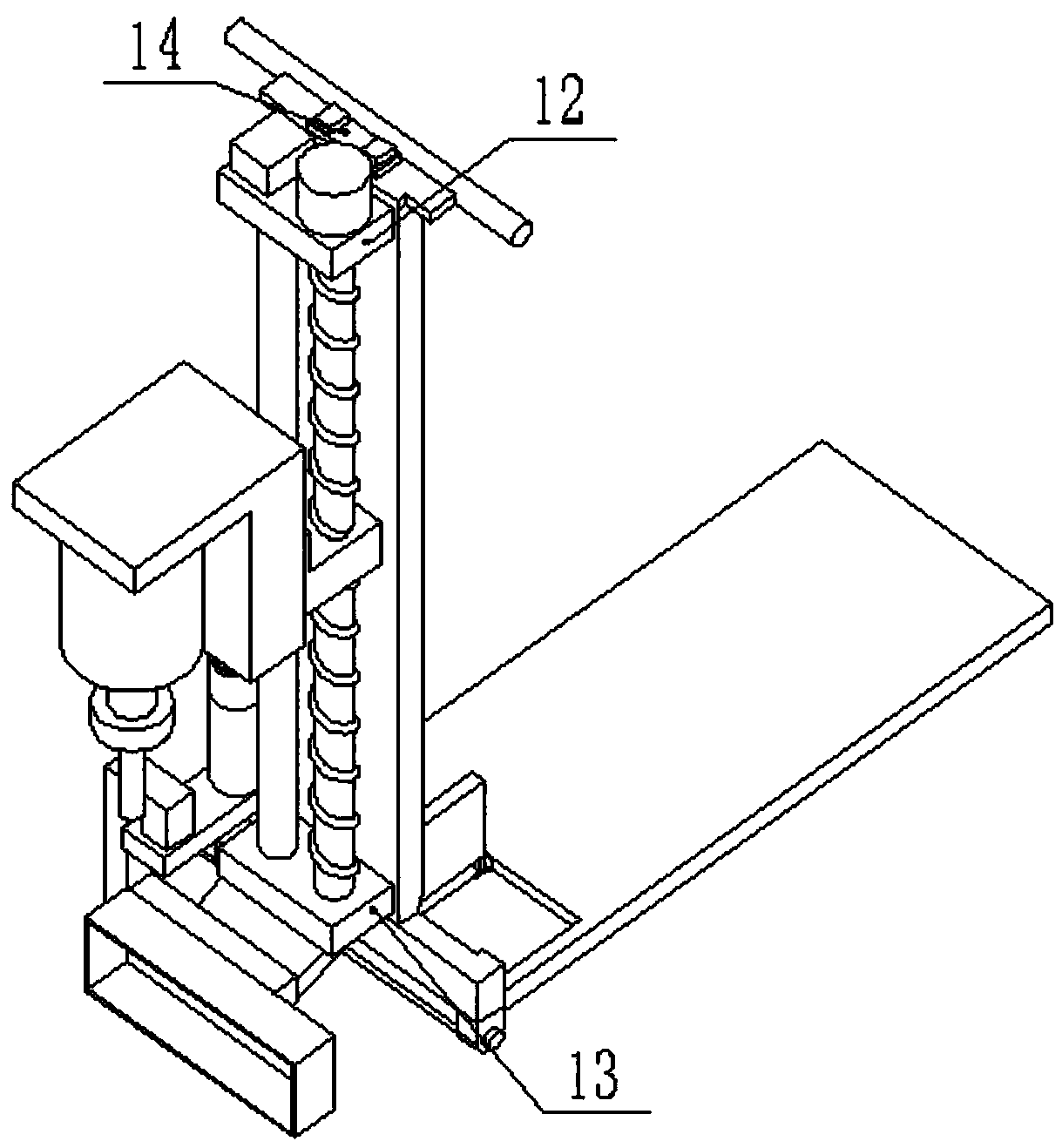

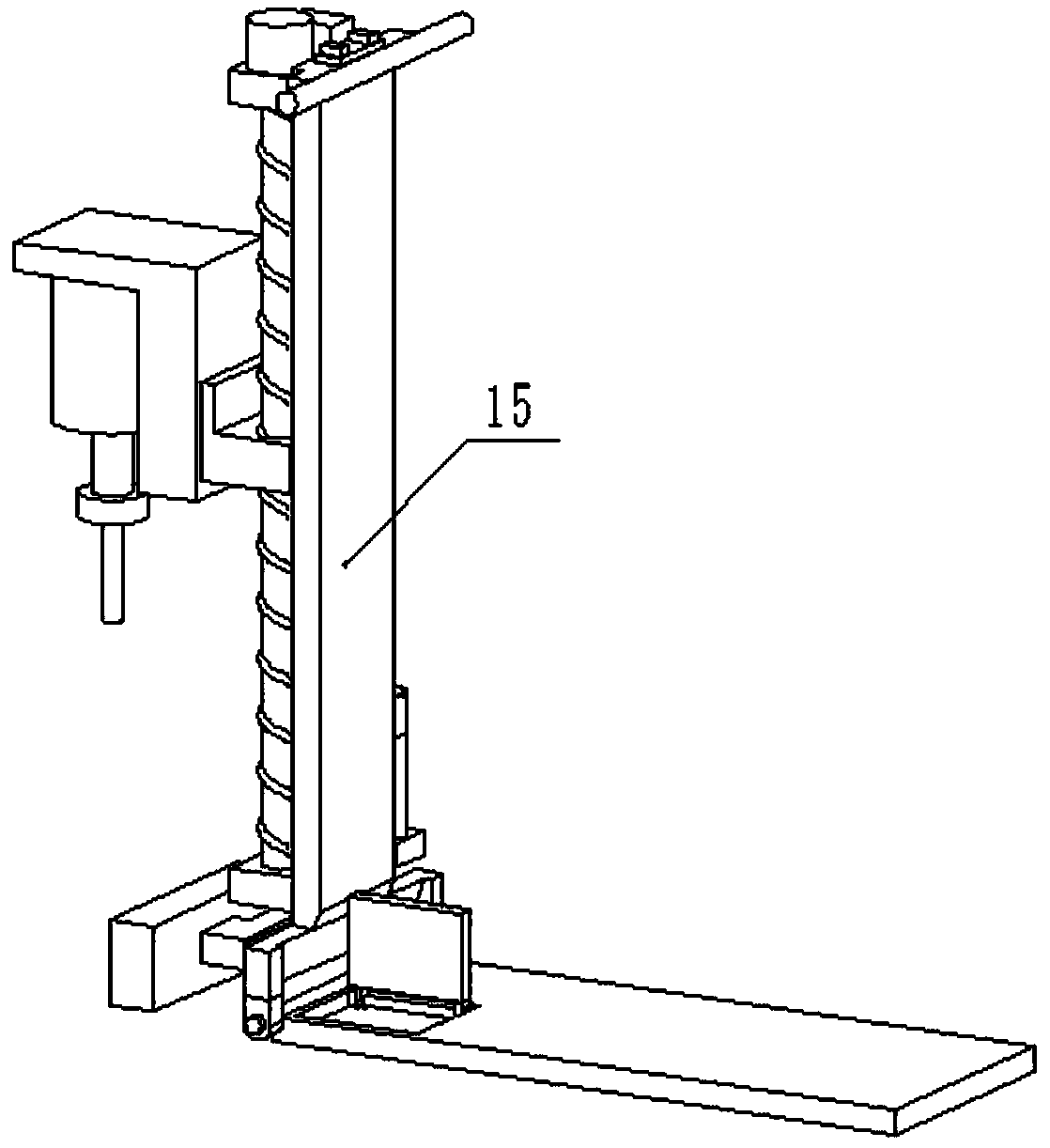

[0020] The present invention is realized through the following technical solutions:

[0021] An environment-friendly automatic drilling device, including a handheld bracket 1, a first motor 2, a controller 3, a lead screw 4, a slide rail 5, a second motor base 6, a second motor 7, a lead screw nut 8, and a drill bit 9 , suction device 10, fixing device 11, first motor base 12, slide rail base 13, button 14, first support 15, second support 16, air extraction device 17, third support 18 and rotating support 19, The hand-held support 1 is a cylindrical structure with a length of 30 centimeters, which is fixed on the top of the first support 15, and the worker can easily carry out the drilling operation by holding the hand-held support 1, and the first motor 2 is installed on the first motor base 12 On the right side of the top, its main shaft is connected to the lead screw 4, and the lead screw nut 8 drives the drill bit 9 to move downward through the rotation of the first motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com