Ultra-long drive shaft and preparation method thereof

A drive shaft, ultra-long technology, applied in the direction of axles, motor vehicles, elastic suspensions, etc., can solve the problems of unstable axial runout, large disturbance deformation, large driving force consumption, etc., to improve the disturbance strength and The effect of rotating coaxiality, enhancing turning stability, and eliminating safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

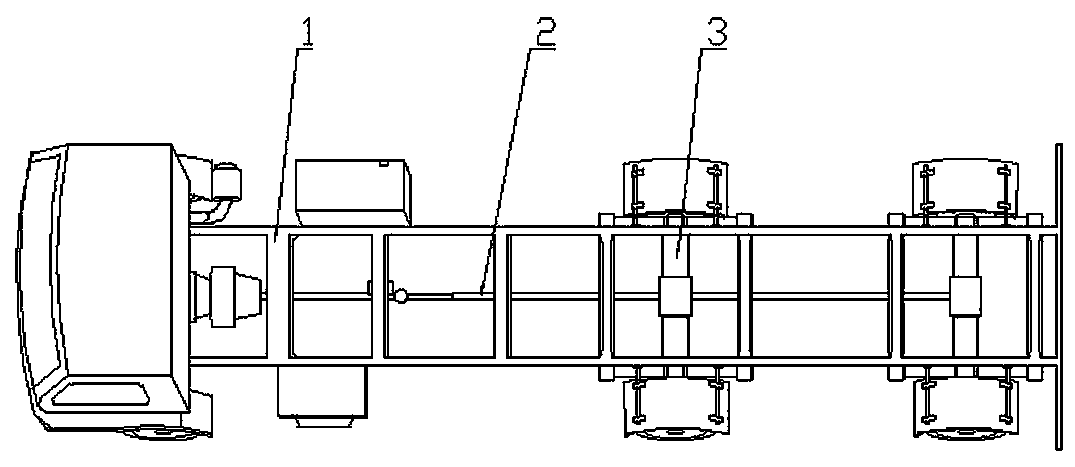

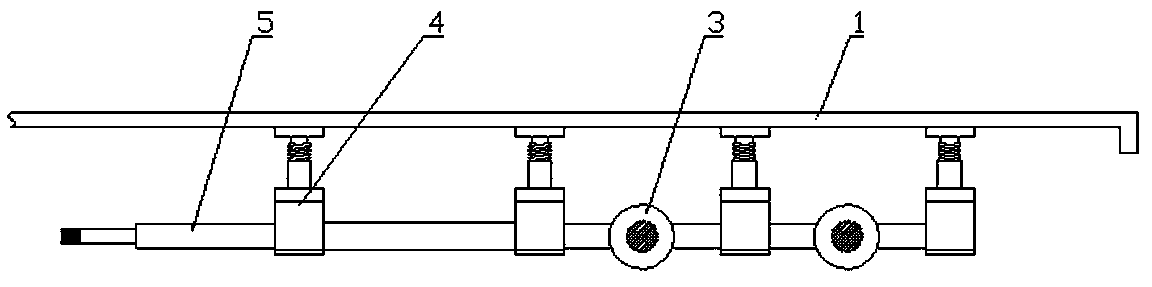

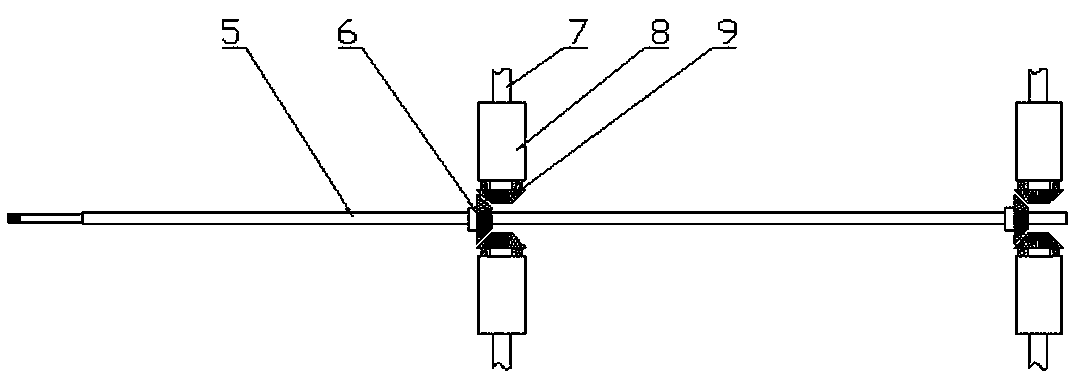

[0035] Embodiment: As shown in the figure, an ultra-long drive shaft includes a chassis frame 1, and is characterized in that: the bottom end of the chassis frame 1 is provided with an ultra-long drive shaft assembly 2, and the ultra-long drive shaft assembly 2 includes a drive shaft 5, which drives the The middle and end of the shaft 5 are respectively provided with a bevel gear I6 that is sleeved with the drive shaft 5, the bevel gear I6 is meshed with the drive axle 3, and there are 4 sets of the drive shaft 5 between the chassis frame 1 and the drive shaft 5. The support frame 4 is connected to the support frame 4. The support frame 4 includes a buffer and shock absorbing member 11. The buffer shock absorbing member 11 includes a pair of symmetrically distributed buffer blocks 14. The end surface of the buffer block 14 is fixed with the bottom of the fixing plate 10. The buffer cylinder 16 is sealed and embedded with the buffer block 14. The upper end of the buffer cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com