Horizontal type continuous production device for phosphorus pentafluoride

A phosphorus pentafluoride and production equipment technology, applied in the field of phosphorus pentafluoride preparation equipment, can solve the problems of out-of-control reaction, high safety risk, unfavorable reaction rate, etc., achieve stable reaction process, constant contact area, and reduce safety risk Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

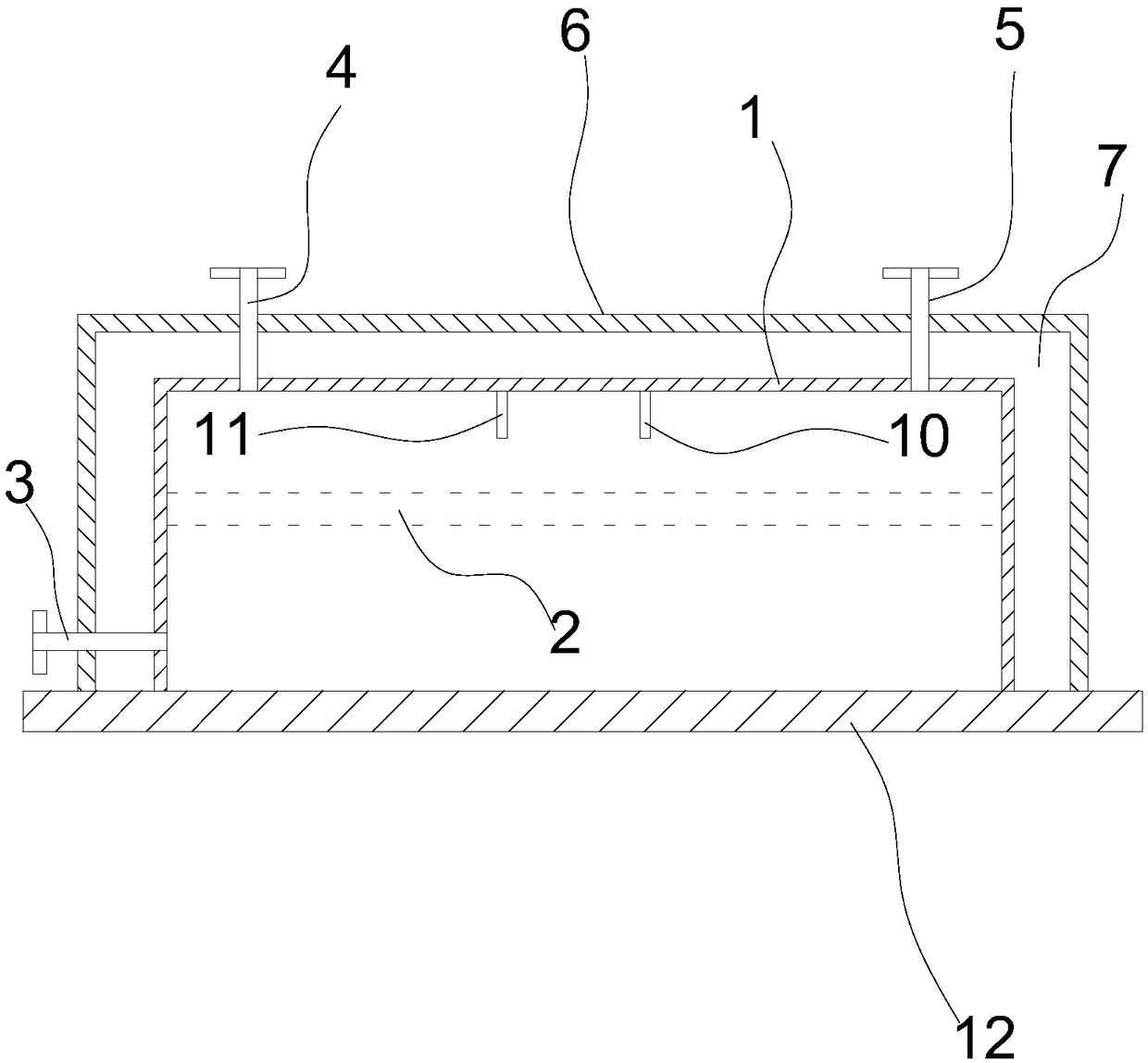

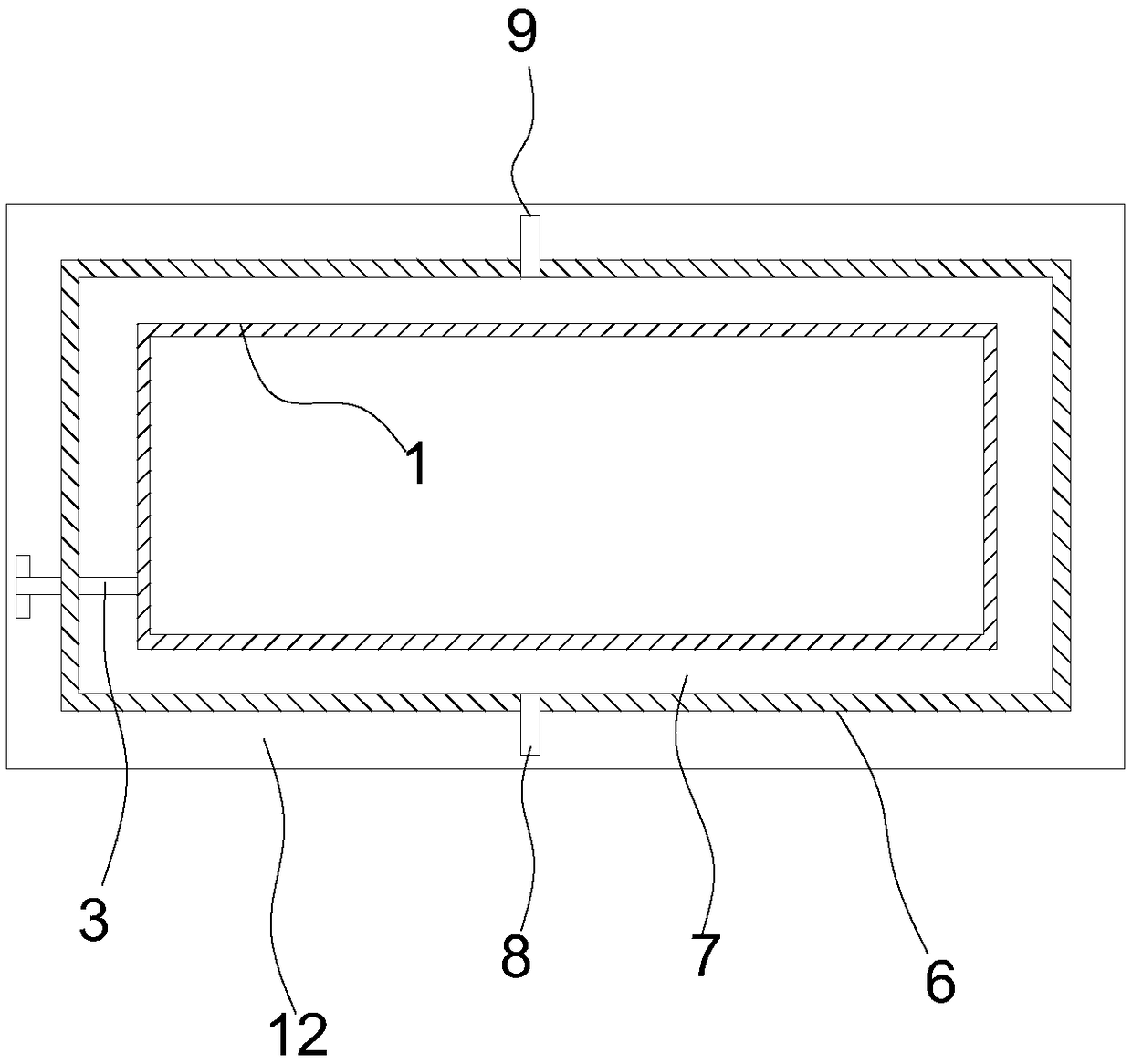

[0015] like figure 1 and figure 2 As shown, the horizontal continuous production equipment of phosphorus pentafluoride of the present invention comprises a horizontal reaction vessel 1, and there is a liquid level maintaining section 2 of a certain height in the inner cavity of the horizontal reaction vessel 1, and the liquid level maintaining The area of the horizontal section at any height of the section 2 is equal, the liquid level maintaining section 2 is provided with a liquid inlet channel 3 below, and the upper horizontal reaction vessel 1 is provided with an air inlet channel 4 at one end and an exhaust channel at the other end 5.

[0016] The horizontal reaction vessel 1 adopts a high-temperature and high-pressure resistant reactor, the liquid inlet channel 3 is used to continuously pass liquid yellow phosphorus into the horizontal reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com