Video monitoring image identification-based automatic coal caving control system

A technology of image recognition and video surveillance, which is applied in mining equipment, earthwork drilling, cutting machinery, etc., can solve the problems of poor versatility and high technical requirements of the automatic coal discharge system, and achieve automatic coal discharge, lower technical requirements, and simplified The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

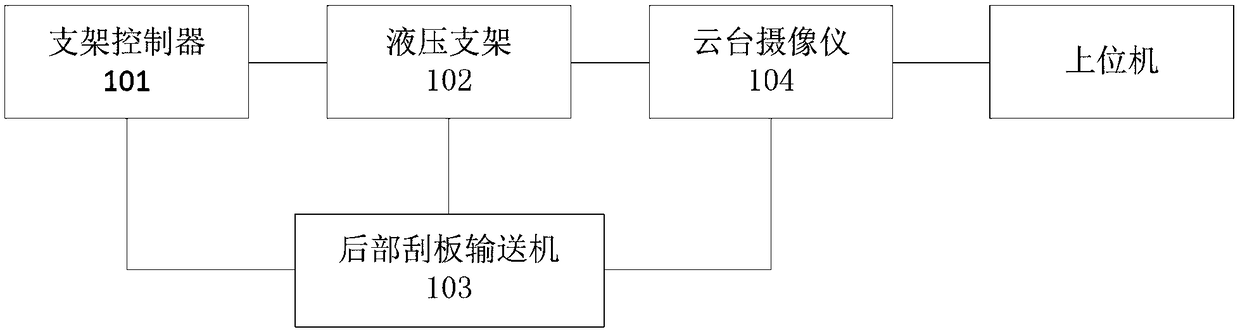

[0039] The embodiment of the present invention provides an automatic coal discharge control system based on video surveillance image recognition, such as figure 1 Shown, comprise support controller 101, hydraulic support 102, rear scraper conveyor 103 and pan-tilt camera 104, wherein:

[0040] The support controller 101 is used to control the action of the hydraulic support 102, by controlling the action of the tail beam and the flashboard of the hydraulic support 102 to control the tail beam to lower the coal; the rear scraper conveyor 103 is arranged on The rear portion of the tail beam of the hydraulic support 102 accepts the coal lowered by the tail beam; the pan-tilt camera 104 is arranged on the tail beam, and it includes a first camera section and a second camera section; The first imaging unit is arranged along the coal conveying direction parallel to the rear scraper conveyor 103, which acquires the coal conveying process image of the rear scraper conveyor; The coal ...

Embodiment 2

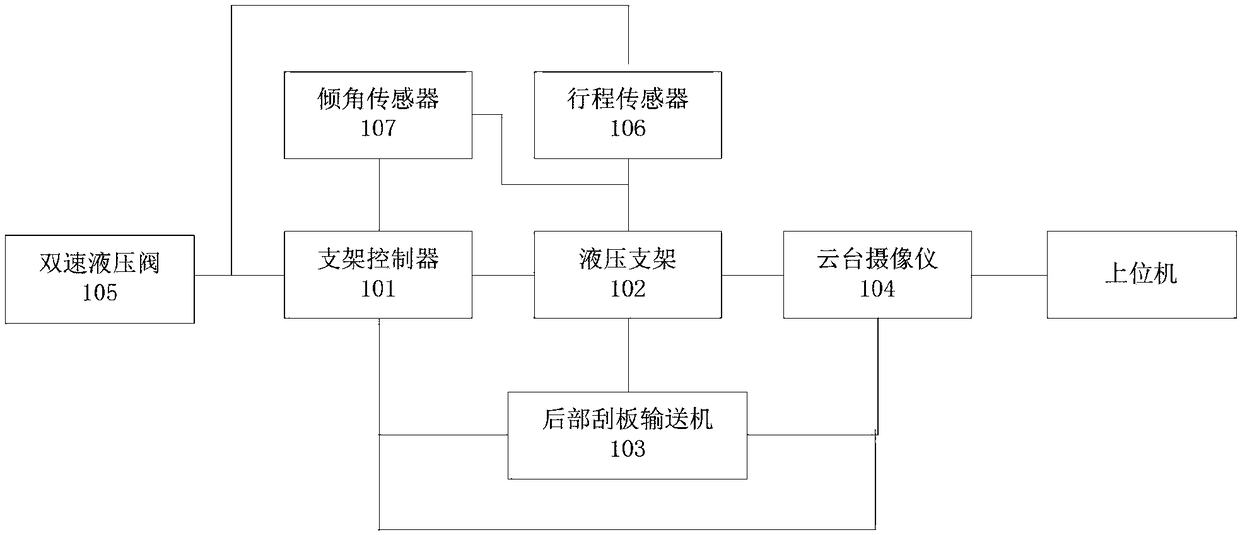

[0046] The automatic coal discharge control system based on video surveillance image recognition provided by this embodiment, such as figure 2 As shown, it may also include a two-speed hydraulic valve 105, a travel sensor 106 and an inclination sensor 107. in:

[0047] The two-speed hydraulic valve 105 is arranged on the liquid supply passage of the hydraulic support 2, and the support controller 101 controls the two-speed hydraulic valve 105 to be placed in the slow position, and the hydraulic support 102 starts at the first speed action; when the support controller 101 controls the two-speed hydraulic valve 105 to be placed in the fast position, the hydraulic support 102 operates at a second speed; the second speed is greater than the first speed.

[0048] The stroke sensor 106 is arranged on the plate cylinder and the rear slide cylinder of the hydraulic support 102, and is used to obtain the stroke of the hydraulic support 102 according to the action of the cylinder, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com