Heat-storage power generation system

A power generation system and heat storage technology, which is applied to machines/engines, steam engine installations, steam applications, etc., and can solve the problems of high wind abandonment rate, deep peak shaving of cogeneration units, and poor thermal and electro-decoupling capability. Realize the effect of load shedding peak regulation and frequency regulation and increase load peak regulation and frequency regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

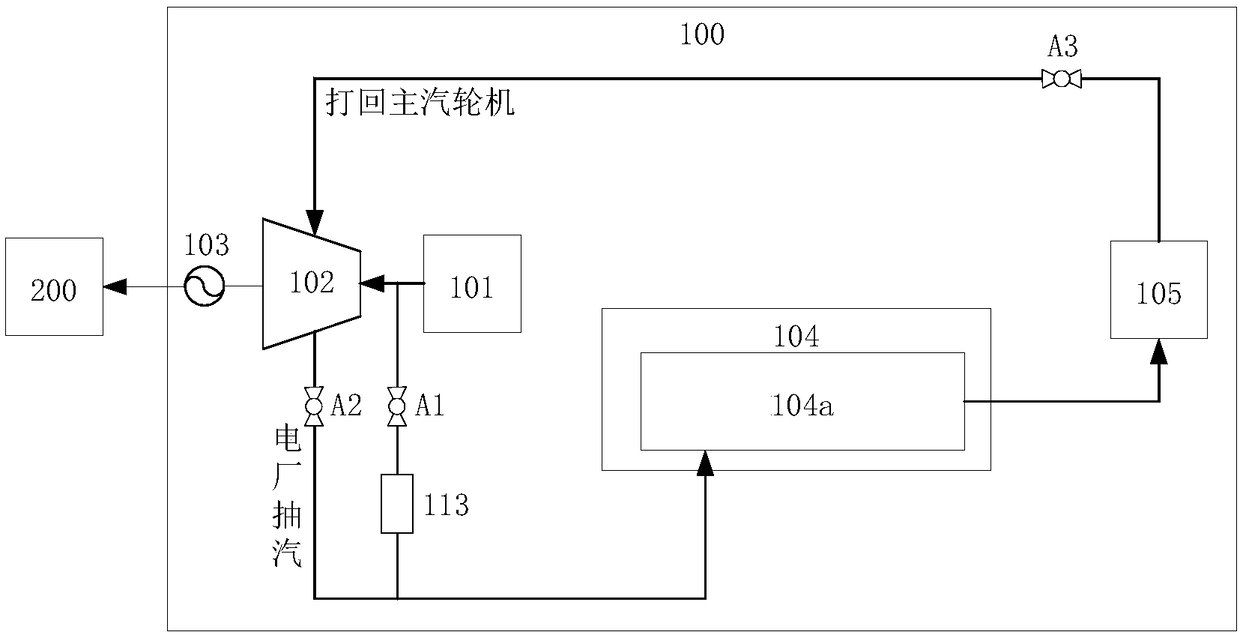

[0037] figure 1 It is a schematic composition diagram of the thermal storage power generation system provided by Embodiment 1 of the present invention.

[0038] Please refer to figure 1 , the present embodiment provides a thermal storage power generation system 100 , including: a main steam boiler 101 , a main steam turbine 102 , a main generator 103 and a steam tank group 104 .

[0039] The main steam boiler 101 is set in the power plant and used to generate steam.

[0040] The main steam turbine 102, the inlet of which communicates with the outlet of the main steam boiler 101, is used to convert steam energy into mechanical energy.

[0041] The main generator 103 is power-connected with the main steam turbine 102 and is used to convert mechanical energy into electrical energy driven by the main steam turbine 102 to supply power to the grid 200 .

[0042] The steam tank group 104 is provided with at least one high-pressure tank 104a, the inlet of the high-pressure tank 104...

Embodiment 2

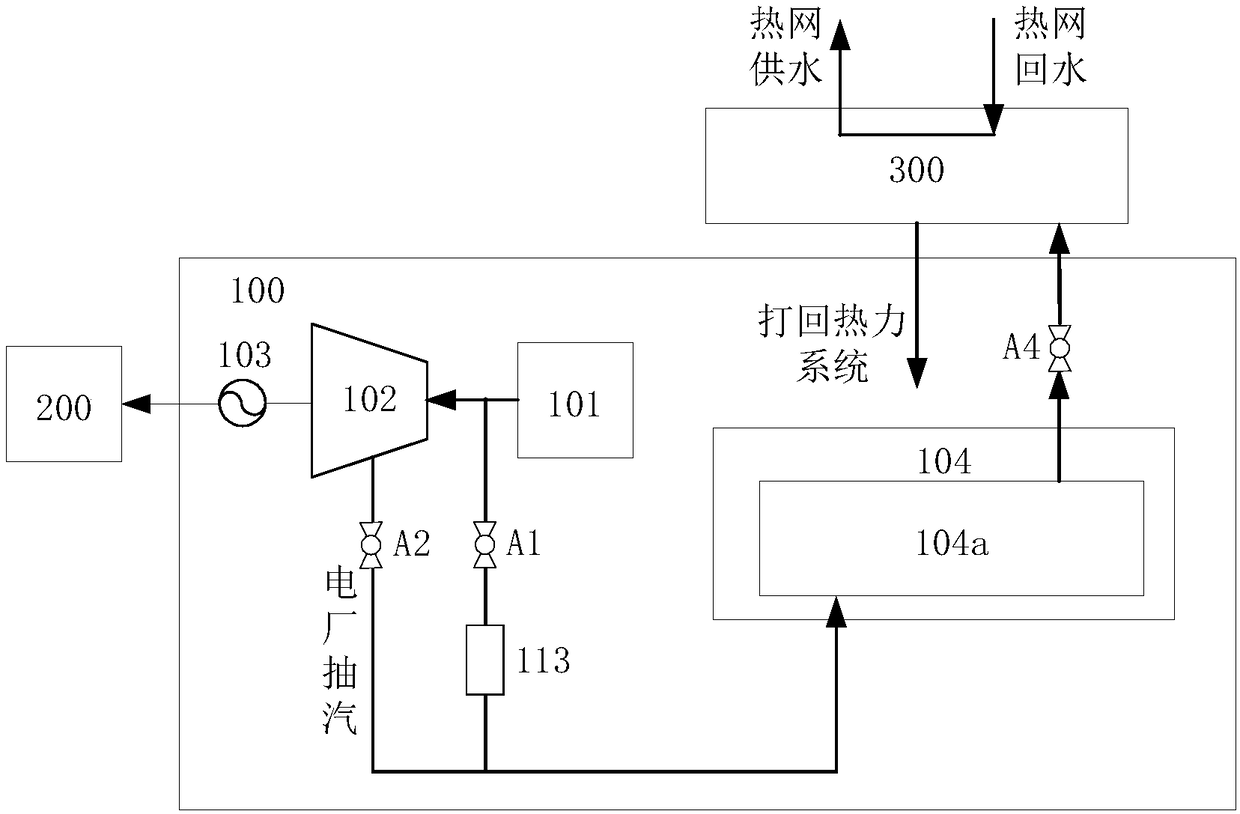

[0061] figure 2 It is a schematic composition diagram of the thermal storage power generation system provided by the second embodiment of the present invention.

[0062] The difference between this embodiment and Embodiment 1 is that the steam stored in the high-pressure tank 104a in this embodiment is used for heating.

[0063] Please refer to figure 2 , in this embodiment, the outlet of the high-pressure tank 104a is connected to the heat network heat exchanger 300, and the steam stored in the high-pressure tank 104a is exchanged with the heat network through the heat network heat exchanger 300 for heat supply.

[0064] Specifically, the outlet of the high-pressure tank 104a is connected to the heat network heat exchanger 300, so that the steam stored in the high-pressure tank 104a is introduced into the heat network heat exchanger 300 for heat exchange for heat supply. After the heat exchange, the steam is condensed into water and Call back the thermal system of the mai...

Embodiment 3

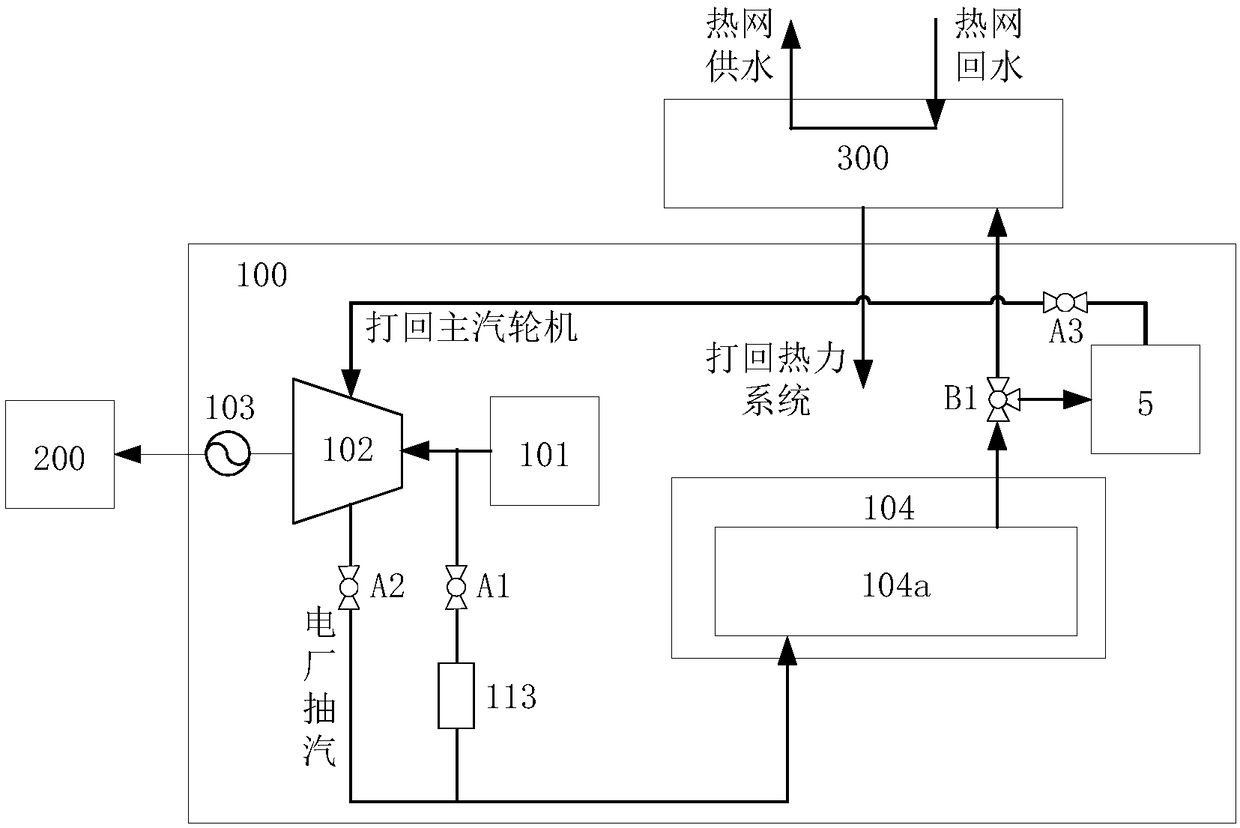

[0077] image 3 It is a schematic composition diagram of the heat storage power generation system provided by Embodiment 3 of the present invention.

[0078] Please refer to image 3 , the thermal storage power generation system 100 in this embodiment is a combination of Embodiment 1 and Embodiment 2, and the two-way valve A4 in Embodiment 2 is replaced by a three-way valve B1.

[0079] In this embodiment, the three-way valve B1 is arranged at the outlet of the high-pressure tank 104a, and is used to divide the outlet of the high-pressure tank 104a into two paths, and one path is connected to the main steam turbine 102 through the first electric superheater 105, so that the high-pressure tank 104a The stored steam is used for power generation at different times, for load-increasing peak-shaving and frequency regulation, and another path is connected to the heat network heat exchanger 300 to introduce the steam stored in the high-pressure tank 104a into the heat network heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com