Sealing device used for brake piston of quick press machine

A sealing device and piston technology, which is applied in fluid pressure actuators, brake actuators, mechanical equipment, etc., can solve the problems of loss of sealing effect and damage of sealing rings, and achieve increased area, stable installation, and optimized flow state Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

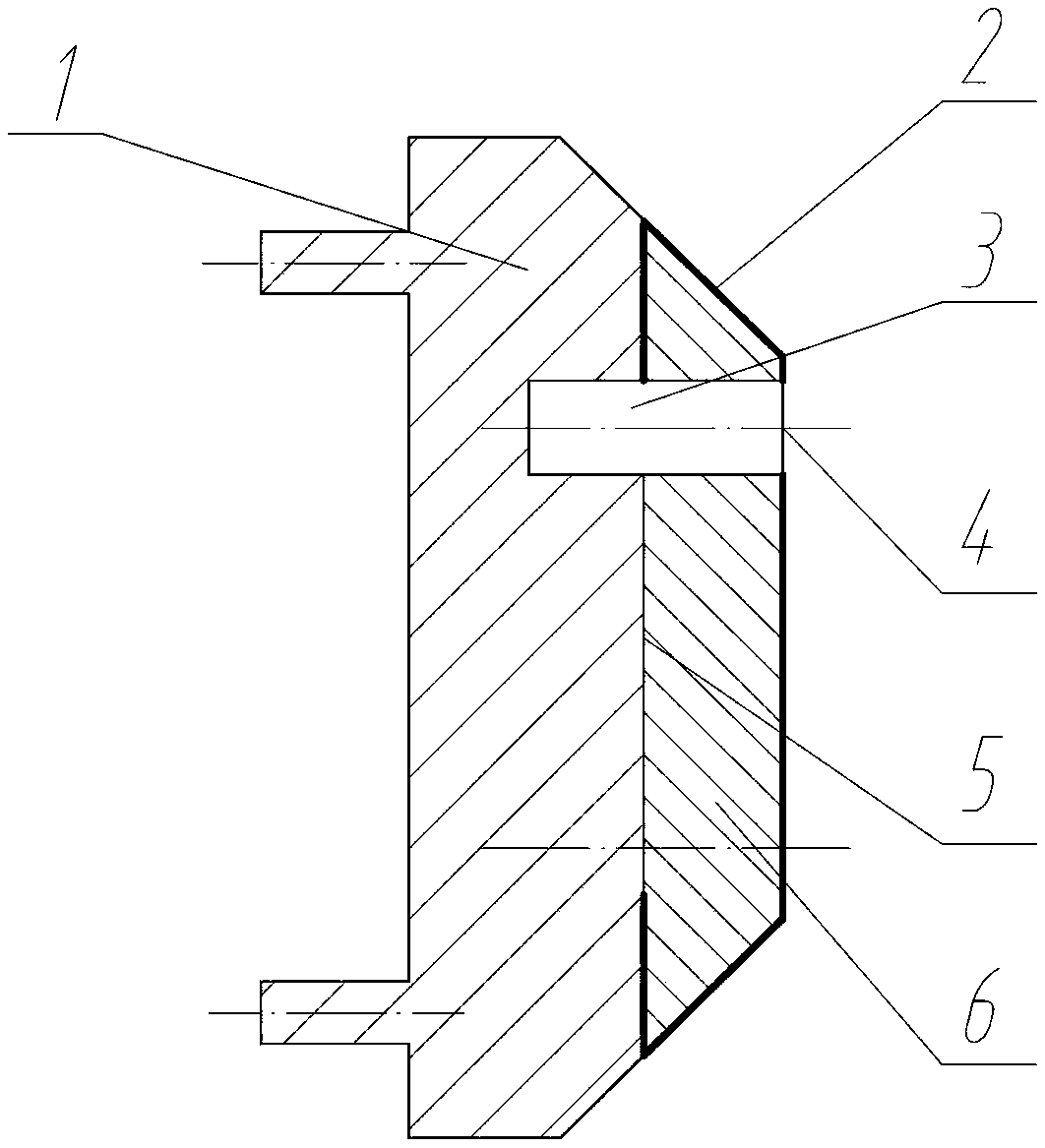

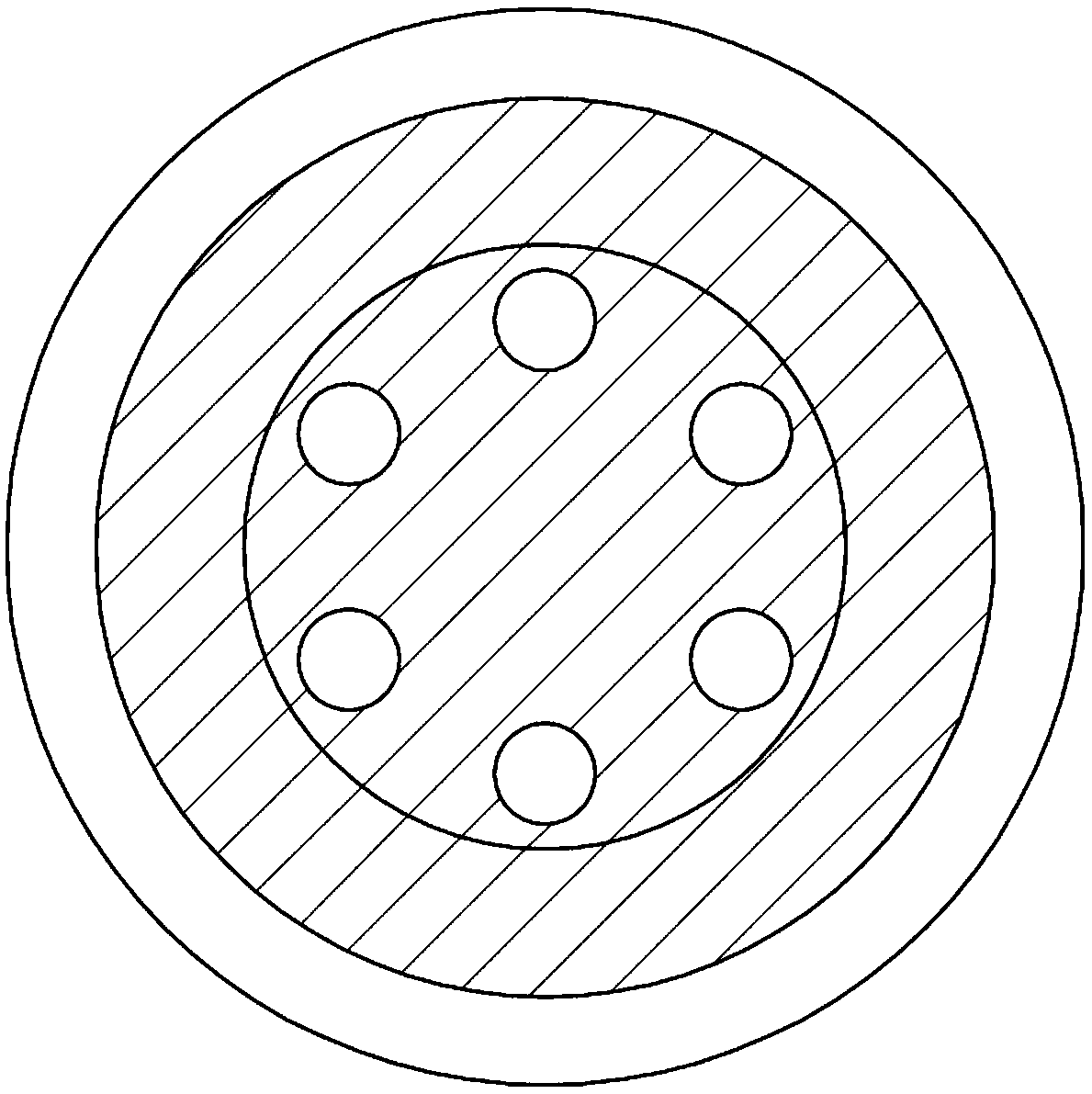

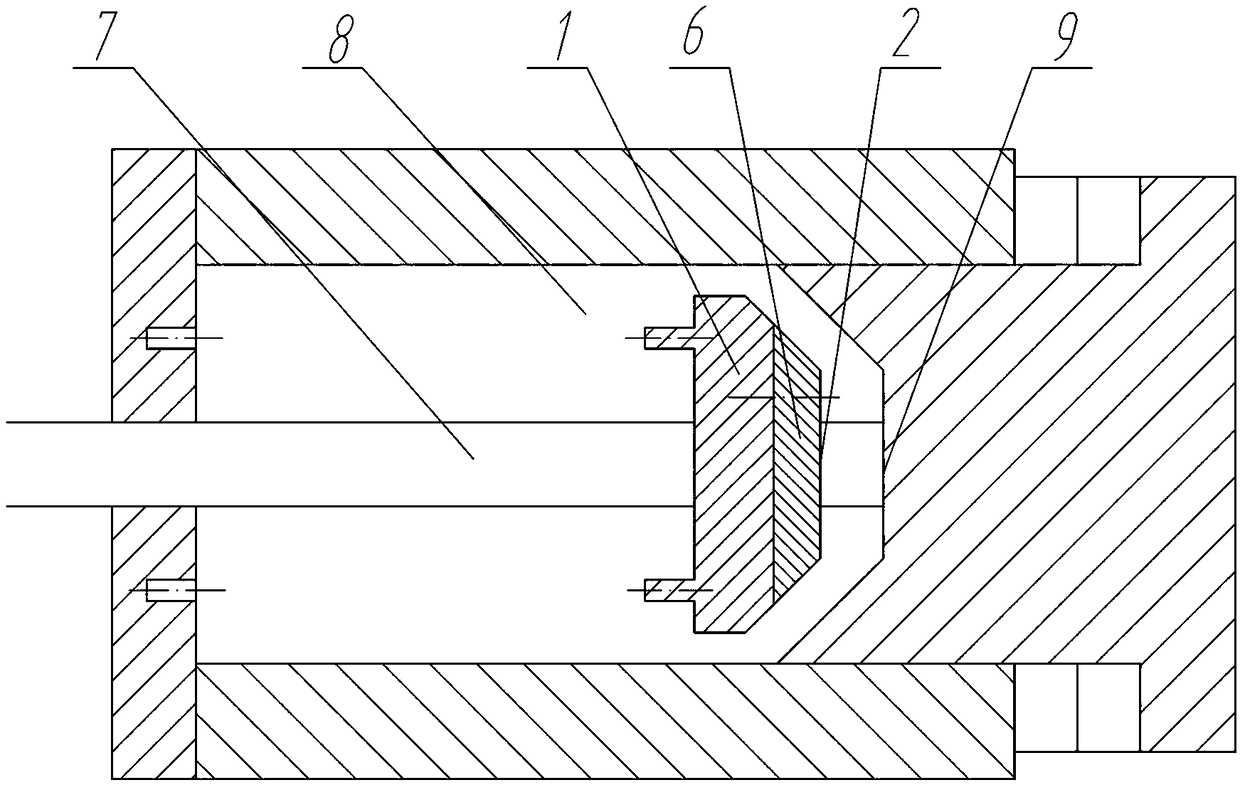

[0023] The disc-shaped brake piston top 6 and the matching disc-groove brake cylinder rear end cover 9 are adopted, and the brake piston top 6 and the brake piston main body 1 are connected by bolts through the reserved bolt holes 3 . Cone type piston top 6 wraps up with the sealing rubber sleeve 2 that size matches with it. The sealing rubber sleeve 2 has a hole at position 3 of the bolt hole on the top of the round table, which is convenient for bolt connection, and an opening at position 5 at the bottom of the round table, which is convenient for the installation of the sealing sleeve.

[0024] Installation method: insert the round table part 6 on the top of the brake piston into the seal sleeve from the opening 5 at the bottom of the seal sleeve, align the bolt holes with the opening 4 of the seal sleeve, and use bolts to connect the top 6 of the brake piston and the main body 1 as a whole , and installed on the connecting rod 7.

[0025] Working process: press the top 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com