Device and method for slag metal high-temperature reaction experiment study in metallurgical process

A technology for high-temperature reaction and experimental research, which is applied in the field of devices for experimental research on slag-gold high-temperature reaction in metallurgical processes, can solve the problems of molten steel or molten slag erosion, uncertainty, high temperature reaction temperature of slag blowing, and achieves low price, The effect of low experiment cost, convenient and fast experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

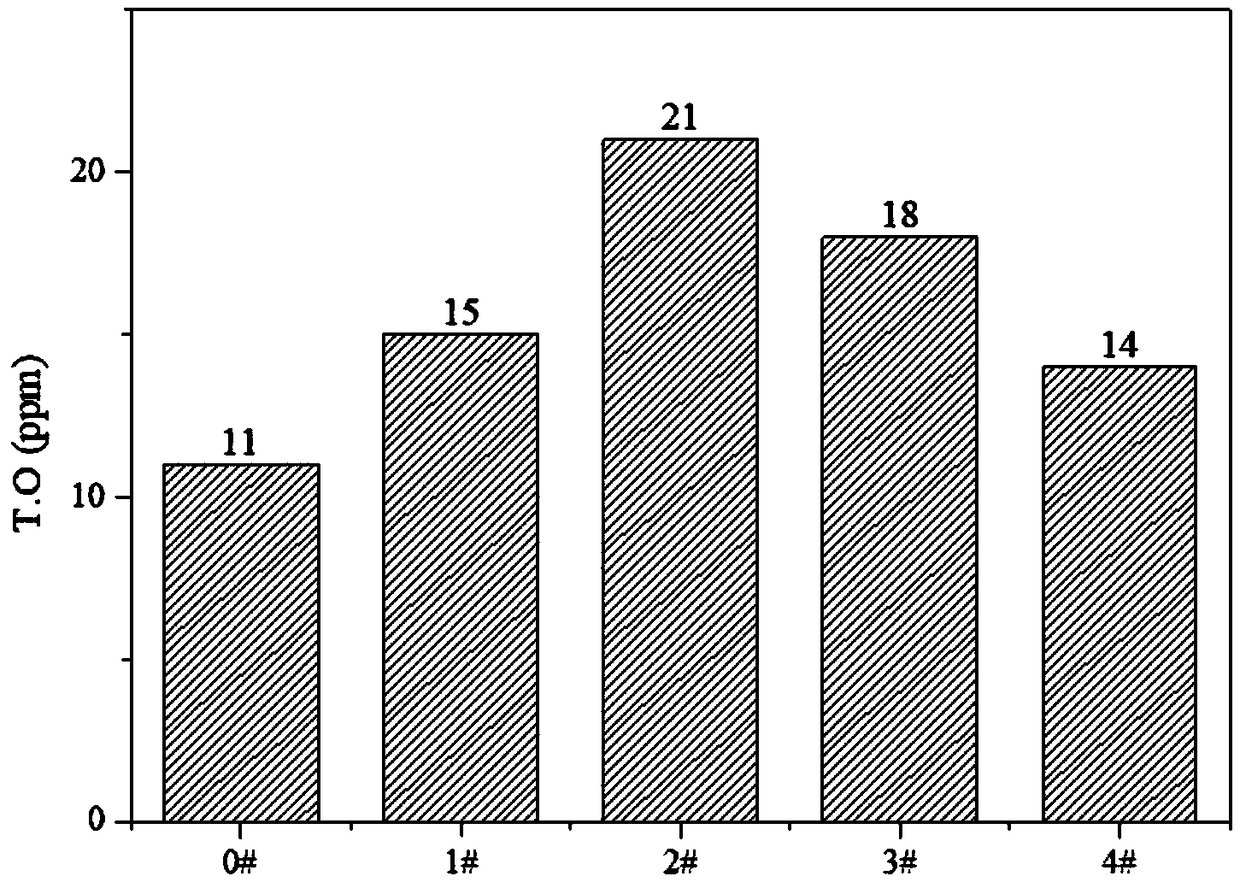

[0041] The slag used in this example was prepared with analytically pure chemical reagents. The specific components and their mass percentages are shown in Table 1. The steel material is GCr15 bearing steel, and the specific components are shown in Table 2.

[0042] Table 1 The chemical composition of the slag used in the experiment

[0043]

[0044] In this embodiment, 50 g of slag and 500 g of steel are used, and the reaction temperature of slag and gold is 1600° C.

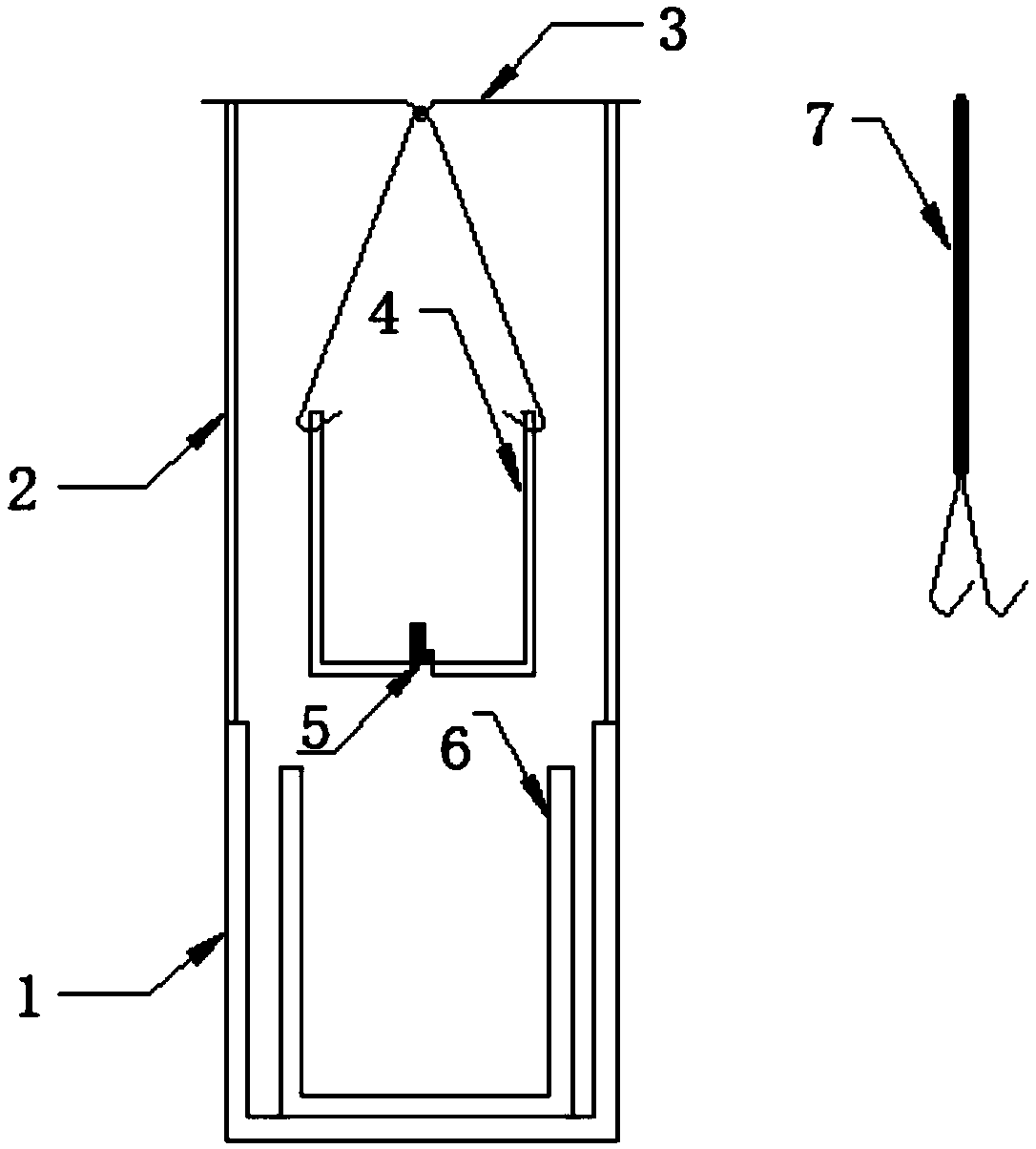

[0045] This embodiment adopts figure 1 The experimental steps of the device in the metallurgical process slag-gold high-temperature reaction experiment are as follows:

[0046] Step 1: At room temperature, put the graphite jacketed crucible, graphite support frame and magnesium oxide crucible with steel material into the heating furnace in sequence according to the structure of the experimental device;

[0047] Step 2: Raise the temperature of the heating furnace. When the temperature of the heating furnac...

Embodiment 2

[0054] The slag used in this example was prepared with analytically pure chemical reagents. The specific components and mass percentages are shown in Table 3. The steel material is M2 high-speed steel, and the specific components are shown in Table 4. The added deoxidizer is rare earth magnesium alloy.

[0055] Table 3 The chemical composition of the slag used in the experiment

[0056]

[0057] In this embodiment, 100 g of slag and 500 g of steel are used, and the reaction temperature of slag and gold is 1500° C.

[0058] This embodiment adopts figure 1 The specific experimental steps for the high-temperature reaction experiment of slag-gold in the metallurgical process are as follows:

[0059] Step 1: At room temperature, put the graphite jacketed crucible, graphite support frame and magnesium oxide crucible with steel material into the heating furnace in sequence according to the structure of the experimental device;

[0060] Step 2: Raise the temperature of the heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com