Method for integrating and optimizing plate type product cut and blanking, box dividing and rack dividing

An optimization method and product technology, applied in the direction of instruments, manufacturing computing systems, data processing applications, etc., can solve problems such as loading errors, failure to consider sub-racks, and unplanned sub-material drop racks, etc., to improve automation levels, speed up production rates, The effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

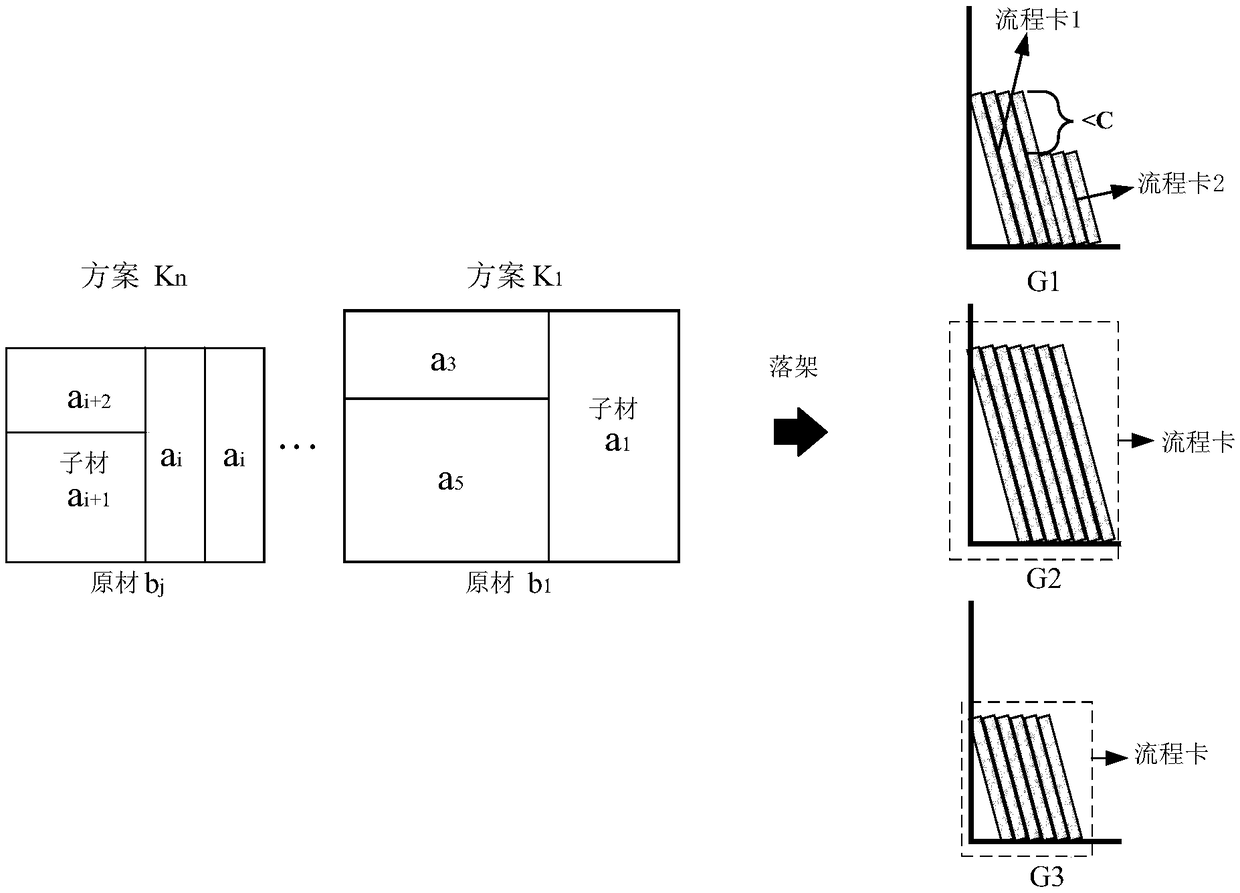

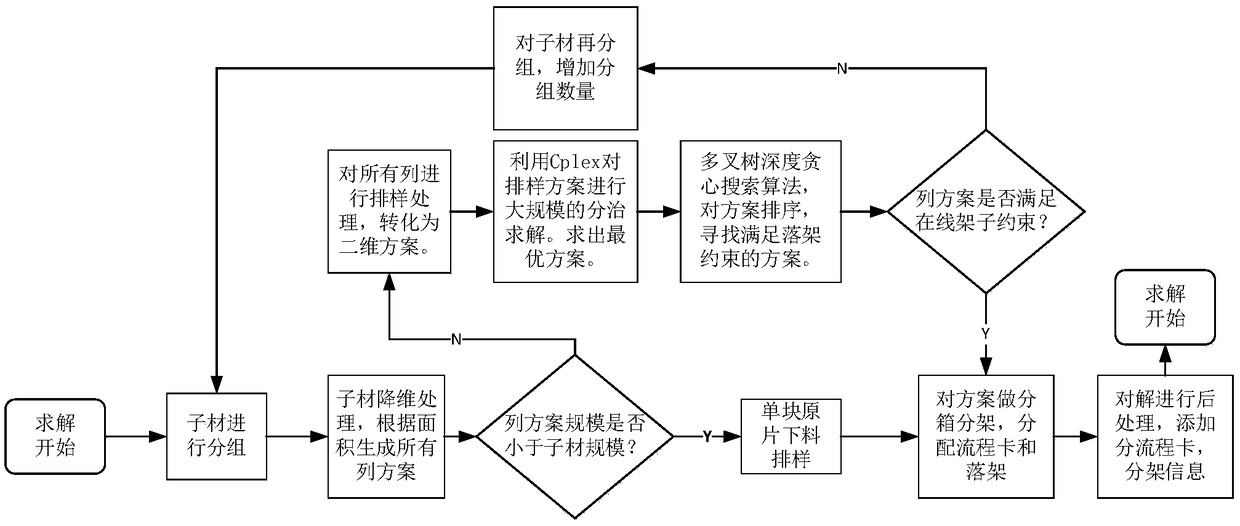

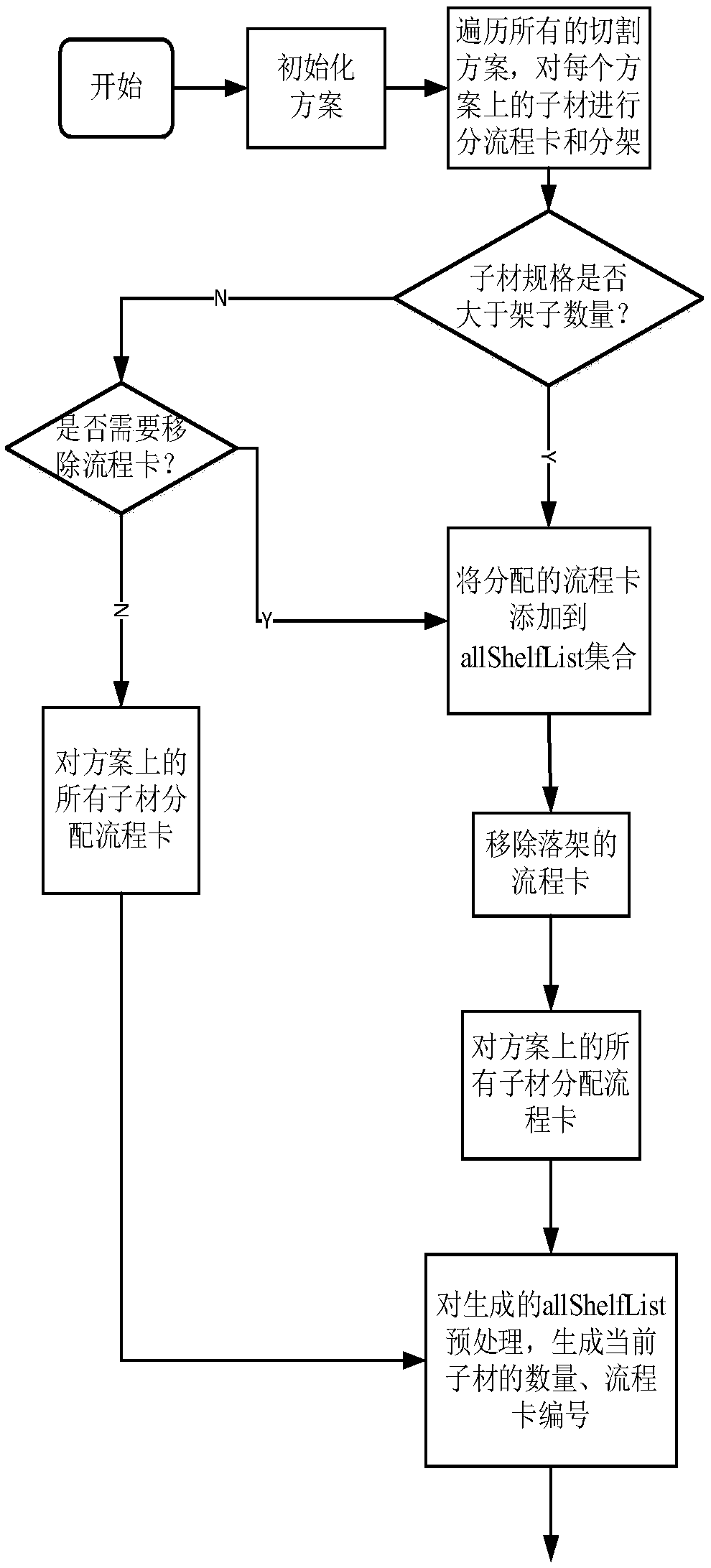

[0043] Such as Figure 1-4 As shown, assuming that there are n types of sub-materials and m types of raw materials, the sub-materials are arranged on the raw materials according to the rules to form a blanking plan k, and the raw materials are cut according to the arrangement of the sub-materials. After cutting, The sub-materials are sorted and loaded onto the racks, and then transported to the next processing equipment for processing through the circulation of the racks. For example, in the process of plate production and processing, the loading of sub-materials is based on the process card, and the cutting of raw materials will form multiple process cards, that is, one process card contains sub-materials of one specification, and one sub-material can be divided into one or more process card. A shelf can be loaded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com