A method of manufacturing a fully insulated lightning arrester

A manufacturing method and lightning arrester technology, which are applied in the direction of adding resistors at the lead-out end and manufacturing encapsulation/shell resistors, etc., can solve problems such as eccentricity of the arrester core group, partial discharge, and uneven thickness of the rubber coating, and achieve uniform rubber coating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: A method for making a fully insulated arrester, suitable for a 10 KV arrester, comprising the following steps:

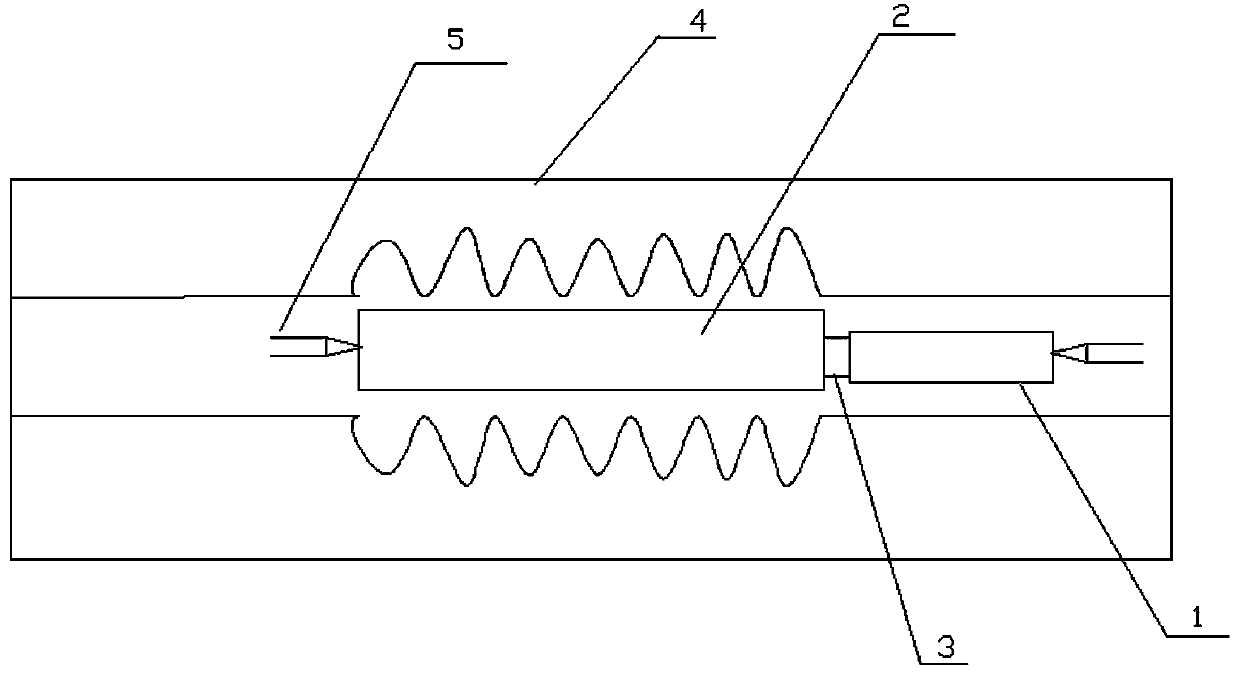

[0019] (1) Use the tooling 1 to replace the insulated lead wire and screw it into the terminal 3 at the end of the wound core group 2, and tighten the connection between the tooling 1 and the terminal 3;

[0020] (2) Put the core group 2 and the tooling 1 into the mold 4 filled with silicone rubber melt, so that the silicone rubber completely covers the core group 2 and the connection between the core group 2 and the tooling 1, and the mold 4 is provided on both sides There is a center positioning device, and the center positioning device is composed of a pair of compression bolts 5 and a positioning frame with internal threads that are matched with the compression bolts. The compression bolts 5 pass through the positioning frame to withstand the core group 2 and the tooling 1 to fix the position of the core group 2 in the mold 4. During the mol...

Embodiment 2

[0023] Embodiment 2: A method for making a fully insulated lightning arrester, suitable for 24 KV lightning arresters, comprising the following steps:

[0024] (1) Use the tooling 1 to replace the insulated lead wire and screw it into the terminal 3 at the end of the wound core group 2, and tighten the connection between the tooling 1 and the terminal 3;

[0025] (2) Put the core group 2 and the tooling 1 into the mold 4 filled with silicone rubber melt, so that the silicone rubber completely covers the core group 2 and the connection between the core group 2 and the tooling 1, and the mold 4 is provided on both sides There is a center positioning device. The center positioning device is composed of a pair of compression bolts 5 and a positioning frame with internal threads that are matched with the compression bolts. end, so that the position of the core group 2 in the mold 4 is fixed, and the core group will not be deviated due to the huge pressure of the machine during the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com