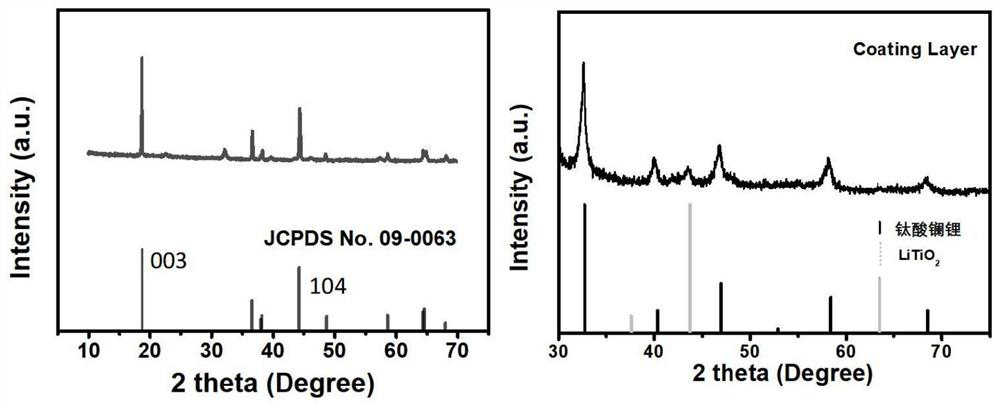

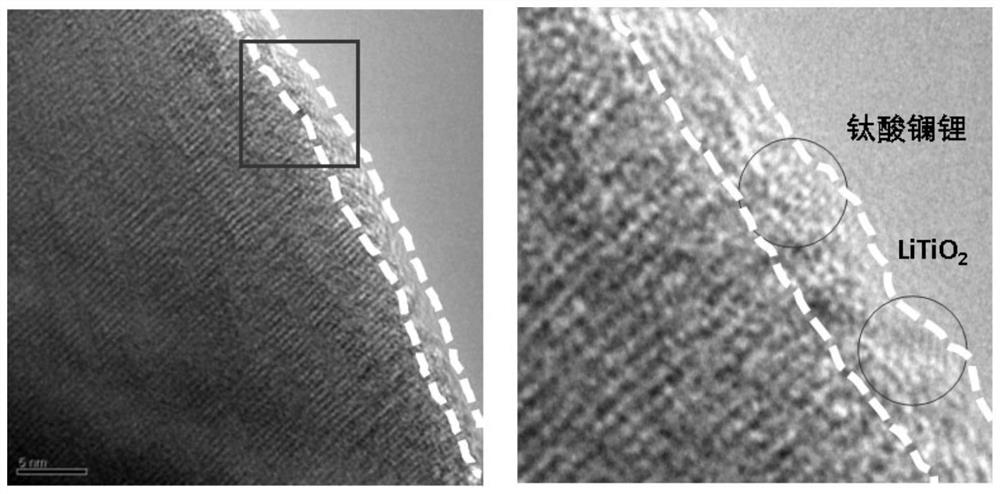

A kind of lanthanum lithium titanate-lithium titanate coated nickel cobalt lithium aluminate positive electrode material and preparation method thereof

A technology coated with nickel-cobalt-aluminate lithium and lithium titanate, applied in positive electrodes, battery electrodes, active material electrodes, etc., can solve problems such as unsatisfactory improvement effects, and achieve excellent electrochemical performance and cycle stability, The effect of stable chemical properties and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

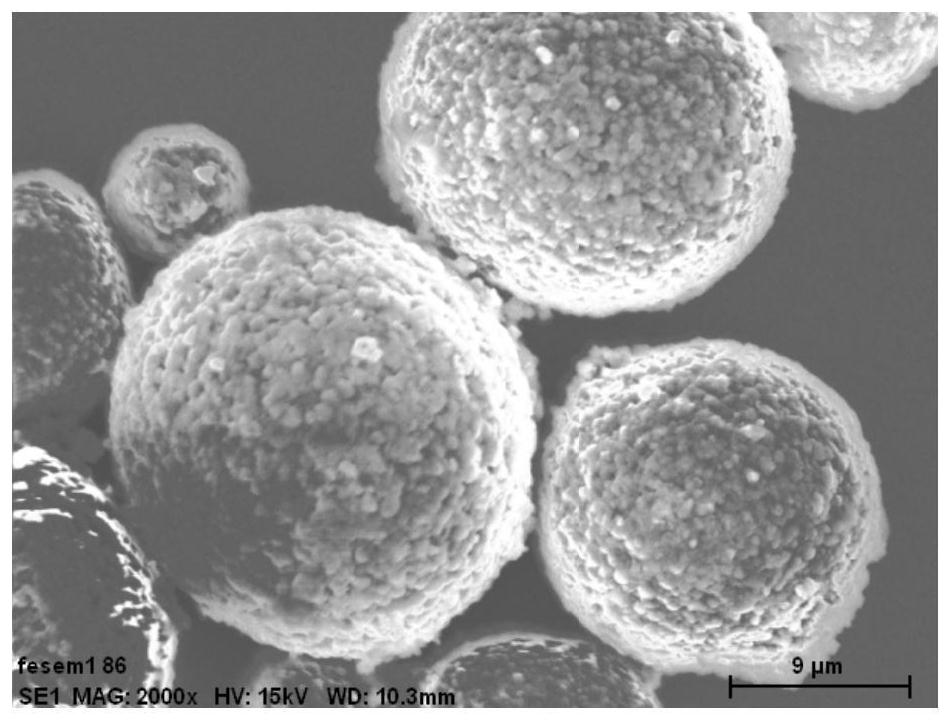

[0051] This embodiment provides a nickel-cobalt-lithium-aluminate cathode material coated with lithium lanthanum titanate-lithium titanate. Prepared by the following preparation method.

[0052] (1) Dissolve tetrabutyl titanate in an appropriate amount of ethanol solvent, after fully stirring, add a certain amount of lanthanum nitrate so that Ti: La is 1:1, and then fully stir until a colorless transparent solution is formed;

[0053] (2) LiNi 0.815 co 0.15 Al 0.035 o 2 and 1wt% (relative to nickel-cobalt-aluminate lithium) of PVP (polyvinylpyrrolidone) were added to the above solution, and placed in a constant water bath at 80°C to fully stir to form a uniform suspension, wherein the molar ratio of titanium and nickel-cobalt-aluminate lithium 1:100;

[0054] (3) Adding deionized water dropwise under stirring conditions to slowly hydrolyze the tetrabutyl titanate, wherein the molar ratio of the amount of deionized water to the added titanium source is 2:1. Stir well unti...

Embodiment 2

[0059] This embodiment provides a nickel-cobalt-lithium-aluminate cathode material coated with lithium lanthanum titanate-lithium titanate. Prepared by the following preparation method.

[0060] (1) Dissolve tetraisopropyl titanate in an appropriate amount of ethylene glycol solvent, after fully stirring, add a certain amount of lanthanum acetate so that Ti: La is 1:2, and then fully stir until a colorless transparent solution is formed;

[0061] (2) LiNi 0.9 co 0.07 Al 0.03 o 2 and 0.5wt% (relative to lithium nickel cobalt aluminate) of CTAB (cetyltrimethylammonium bromide) were added to the above solution, and placed in a constant water bath at 80 ° C to fully stir to form a uniform suspension, wherein titanium and The molar ratio of nickel cobalt lithium aluminate is 0.5:100;

[0062] (3) Adding deionized water dropwise under stirring conditions to slowly hydrolyze the tetrabutyl titanate, wherein the molar ratio of the amount of deionized water to the added titanium s...

Embodiment 3

[0065] This embodiment provides a nickel-cobalt-lithium-aluminate cathode material coated with lithium lanthanum titanate-lithium titanate. Prepared by the following preparation method.

[0066] (1) Dissolve tetrabutyl titanate in an appropriate amount of glycerol solvent, and after fully stirring, add a certain amount of lanthanum nitrate so that Ti:La is 2:1, and then fully stir until a colorless transparent solution is formed;

[0067] (2) LiNi 0.8 co 0.15 Al 0.05 o 2 and 2wt% (relative to nickel-cobalt-aluminate lithium) of PVP (polyvinylpyrrolidone) were added to the above solution, and placed in a constant water bath at 80°C to fully stir to form a uniform suspension, wherein the molar ratio of titanium to nickel-cobalt-aluminate lithium is 2:100;

[0068] (3) Deionized water was added dropwise under stirring to slowly hydrolyze tetrabutyl titanate, wherein the molar ratio of the amount of deionized water to the added titanium source was 2:1. Stir well until the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com