Mixed-fermentation mixed meal and production process and application thereof

A technology of mixed fermentation and production technology, applied in application, food processing, animal feed, etc., can solve the problems of large damage to the nutritional components of miscellaneous meal, high crude fiber content, limited application scope and dosage, etc., and achieve the nutritional value of protein. and absorption and utilization, increase the content of metabolites, and increase the effect of digestion and utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1, the preparation method of mixed fermentation miscellaneous meal

[0039] 1) Preparation of compound miscellaneous meal raw materials. Take peanut meal (protein ≥ 48%) 300kg, cottonseed meal (protein ≥ 43%) 250kg, sunflower meal (protein ≥ 42%) 200kg, rapeseed meal (protein ≥ 40%) 150kg, corn flour 50kg, bran 50kg , stir evenly with a mixer (stirring time 5min, speed 60rpm);

[0040]2) Preparation of compound fermentation broth. The strains for preparing the composite fermentation bacteria are Bacillus subtilis, Aspergillus oryzae, Saccharomyces cerevisiae and Lactobacillus acidophilus, and the mass ratio is 200:2500:500:300. Add 200g of Bacillus subtilis, 2500g of Aspergillus oryzae, 500g of Saccharomyces cerevisiae and 300g of Lactobacillus acidophilus into 100L of warm water at 35°C, add 3kg of brown sugar, and stir with a stirrer (stirring time 20min, speed 40-60rpm) Mix evenly to make a compound fermentation broth.

[0041] 3) Inoculate the raw mat...

Embodiment 2

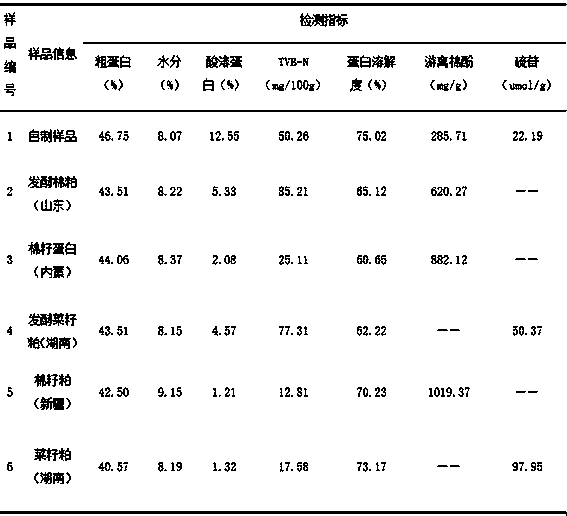

[0044] Embodiment 2, the comparative analysis of the nutritive value of mixed fermented miscellaneous dregs

[0045] 1 test material

[0046] The mixed fermented miscellaneous meal obtained in the above example 1 is sample 1; 3 similar fermented products on the market are collected, namely sample 2, sample 3, and sample 4; untreated cottonseed meal is sample 5; untreated rapeseed meal is sample 6.

[0047] 2 test method

[0048] The above samples were tested for crude protein, moisture, particle size, acid-soluble protein, protein solubility, volatile basic nitrogen (TVB-N), free gossypol, and glucosinolate content according to the following detection methods. Specific detection methods refer to the following:

[0049] (1) Crude protein: according to the provisions of GB / T 6432

[0050] (2) Moisture: According to the regulations of GB / T 6435-2006

[0051] (3) Free gossypol: according to the regulations of GB / T5009.148-2011

[0052] (4) Particle size: according to the prov...

Embodiment 3

[0076] Embodiment 3, the influence of product of the present invention replacing fishmeal on production performance and economic benefit of weaned piglets

[0077] 1 Experimental design

[0078] A total of 120 weaned piglets with similar parity and healthy initial weight of about 7.6kg were selected and divided into 3 groups, namely the imported fishmeal group (Tianjin Yuanping International Trade Co., Ltd., imported fishmeal from Peru), fermented soybean meal group (Wuhan Bangzhi German) and the product group of the present invention, the premix is the product of Jinan Oviple Animal Nutrition Co., Ltd. (main ingredients: 8% plasma protein powder, 3% glucose, 0.2% cooked soybean oil, 30% acidified milk substitute powder, zeolite powder 13.385%, whey powder 12%, hemoglobin powder 10%, skin red pigment 0.1%, acidulant 2.4%, flavoring agent 0.2%, super sweetener 0.2%, 0.5% suckling pig core material 0.45%, calcium hydrogen phosphate 8.5%, fine stone powder 6%, salt 2.4%, 50% c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com