Comprehensive processing method of organic oat fiber powder, oat protein powder and oat germ powder

A comprehensive processing and oat fiber technology, which is applied in the comprehensive processing of oat protein powder and oat germ powder, and in the field of organic oat fiber powder, can solve the problem of single product, achieve the effect of product variety, increase extraction rate and increase screening accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

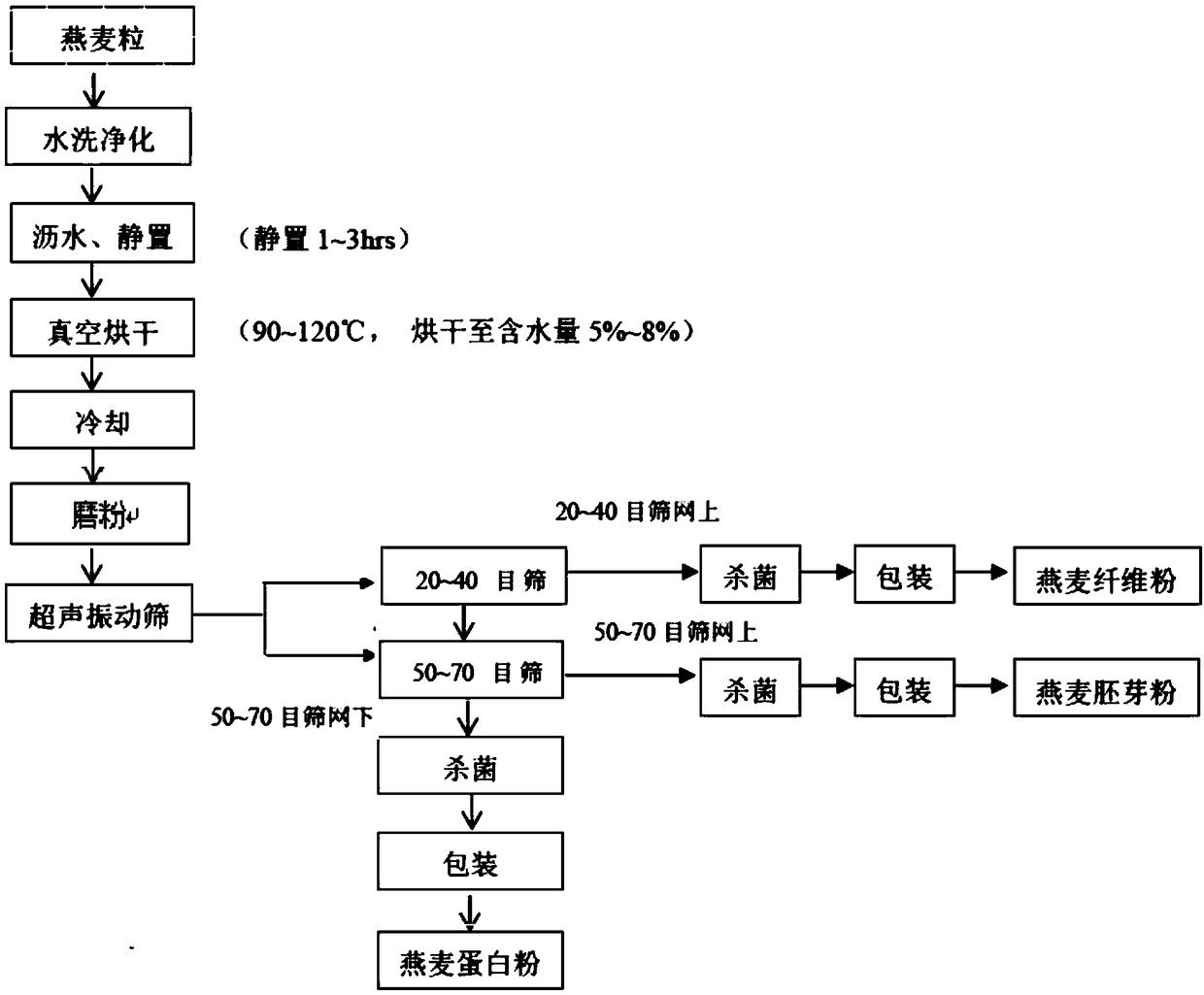

[0027] Embodiment: the processing of organic oat fiber powder, oat protein powder and oat germ powder product

[0028] 1. Weigh 5 kg of organic oat grain raw material, add it to the washing machine for washing and purification, and let it stand for 1 to 3 hours to drain after cleaning;

[0029] 2. Put the washed and drained oat grains into a vacuum drying oven for vacuum drying, set the temperature at 90-120°C, dry until the moisture content is about 5-8%, and cool;

[0030] 3. Grinding the dried and cooled oat grains;

[0031] 4. Put the ground oats into the ultrasonic vibrating sieve, set the equipment modulus (17-20: 21-23), and sieve; the oat flour first passes through the 20-40 mesh sieve, and collects the 20-40 mesh sieve The main component of the upper part of the net is oat fiber powder; then it is separated through a 50-70 mesh sieve, and the part below the sieve is collected. The main component is oat protein powder, which is between 20-40 mesh and 50-70 mesh The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com