Solid preparation and preparation method thereof

A technology for solid preparations and adhesives, which is applied in the directions of pill delivery, pharmaceutical formulations, and medical preparations with non-active ingredients, etc., can solve problems such as the limitation of viscosity properties of active ingredients, shorten research and development time, improve quality, and improve industrialization. potential effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

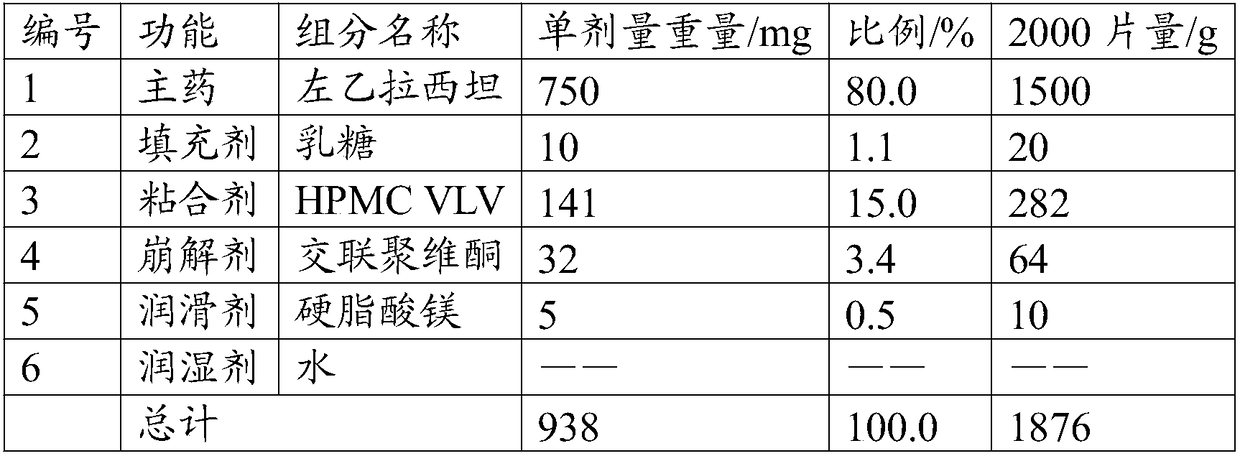

[0039] The present embodiment provides a solid preparation with high drug loading, and its prescription is as follows:

[0040]

[0041] Its preparation method is as follows:

[0042] (1) Pulverize the main ingredient so that 60% of the weight passes through a 200 mesh sieve, and the weight of more than 60 mesh sieve is less than 2%. Combine with the sieved filler and disintegrant, and pre-mix for 5 minutes in a high-shear granulator to obtain a pre-mixed material.

[0043] (2) The binder is formulated into an aqueous solution with a mass concentration of 25%, added to the premixed material, granulated by a high-shear granulator, dried at 50°C for 10 minutes, and granulated to obtain a dry intermediate, wetted The agent water is eventually removed.

[0044] (3) Add a lubricant to the dry intermediate and mix for 5 minutes to obtain granules.

[0045] (4) Compressing the prepared granules with a tablet machine to obtain the solid preparation with high drug loading.

[00...

Embodiment 2

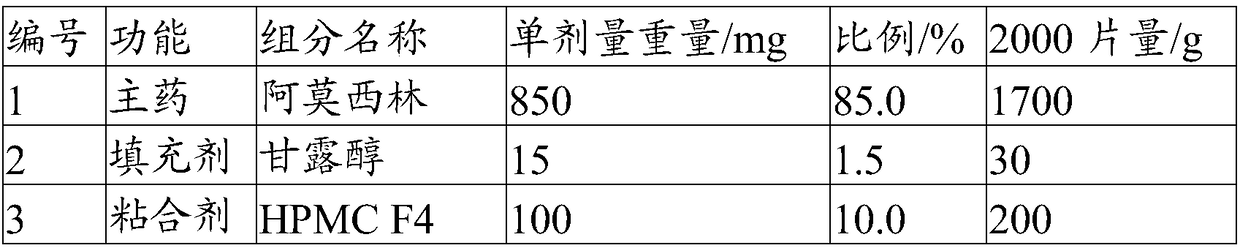

[0049] The present embodiment provides a solid preparation with high drug loading, and its prescription is as follows:

[0050]

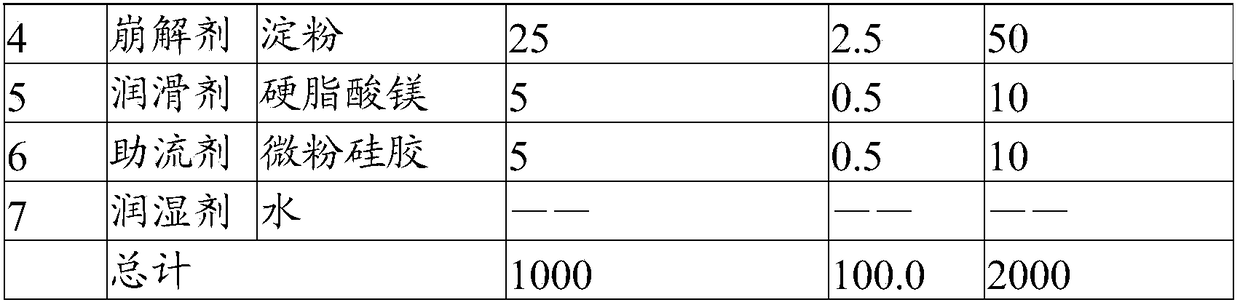

[0051]

[0052] Its preparation method is as follows:

[0053] (1) Pulverize the main ingredient so that 60% of the weight passes through a 200 mesh sieve, and the weight of more than 60 mesh sieve is less than 2%. Combine with the sieved filler and disintegrant, and pre-mix for 5 minutes in a high-shear granulator to obtain a pre-mixed material.

[0054] (2) The binder is formulated into an aqueous solution with a mass concentration of 20%, added to the premixed material, granulated by a high-shear granulator, dried at 50°C for 8min, and granulated to obtain a dry intermediate, wetted The agent water is eventually removed.

[0055] (3) Add a lubricant and a glidant to the dry intermediate and mix for 5 minutes to obtain granules.

[0056] (4) Compressing the prepared granules with a tablet machine to obtain the solid preparation with high ...

Embodiment 3

[0060] The present embodiment provides a solid preparation with high drug loading, and its prescription is as follows:

[0061]

[0062] Its preparation method is as follows:

[0063] (1) Pulverize the main ingredient so that 60% of the weight passes through a 200 mesh sieve, and the weight of more than 60 mesh sieve is less than 2%. Combine with the sieved filler and disintegrant, and pre-mix for 5 minutes in a high-shear granulator to obtain a pre-mixed material.

[0064] (2) The binder is formulated into an aqueous solution with a mass concentration of 20%, added to the premixed material, granulated by a high-shear granulator, dried at 55°C for 4min, and granulated to obtain a dry intermediate, wetted The agent water is eventually removed.

[0065] (3) Add a lubricant and a glidant to the dry intermediate and mix for 5 minutes to obtain granules.

[0066] (4) Compressing the prepared granules with a tablet machine to obtain the solid preparation with high drug loading...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com