Feed processing and burdening device for quickly mixing and proportioning feed components

A technology for mixed feed and feed processing, applied in feed, mixer, shake/oscillation/vibration mixer, etc., can solve problems affecting feed quality, mass efficiency, uneven mixing, etc., to reduce labor and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

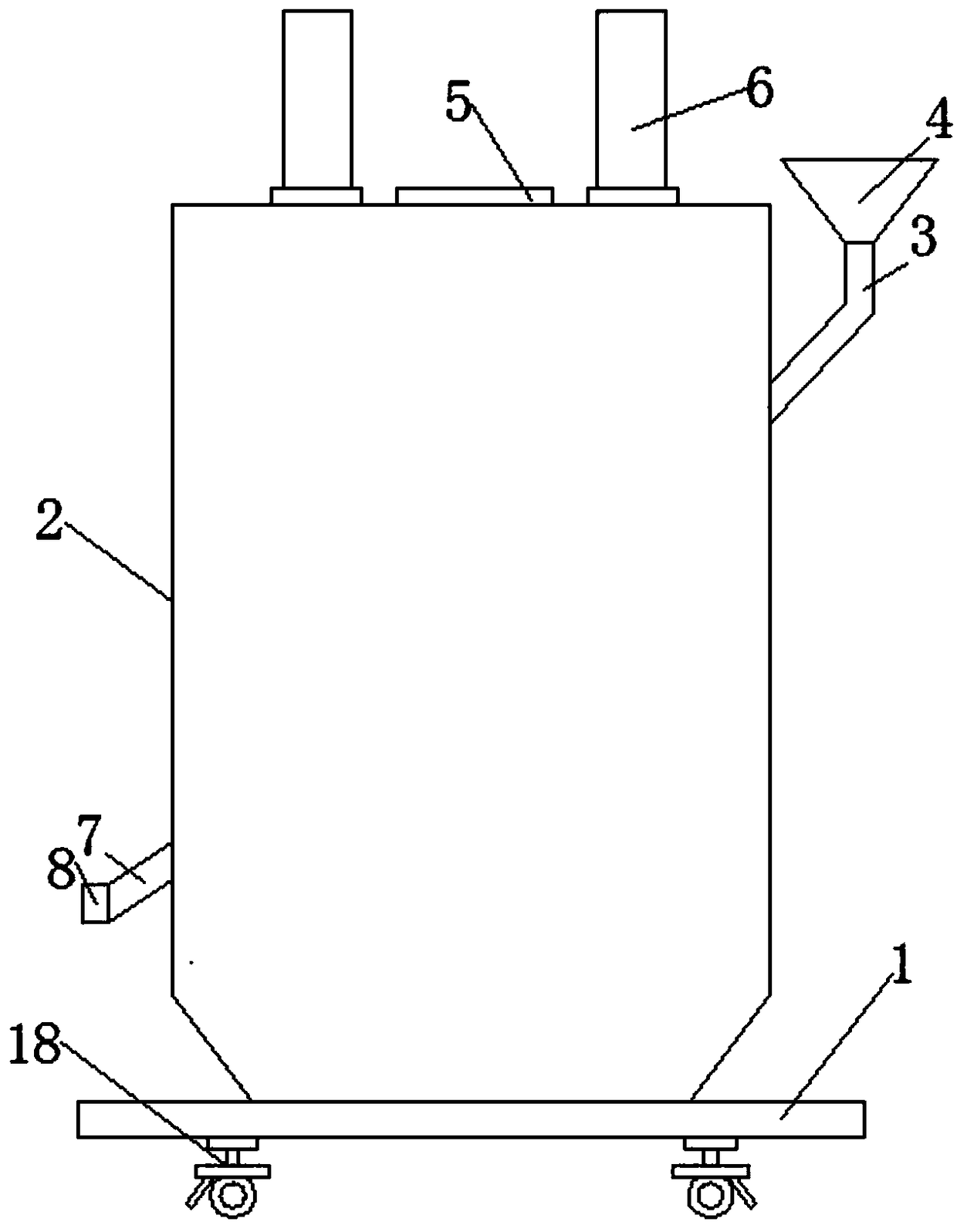

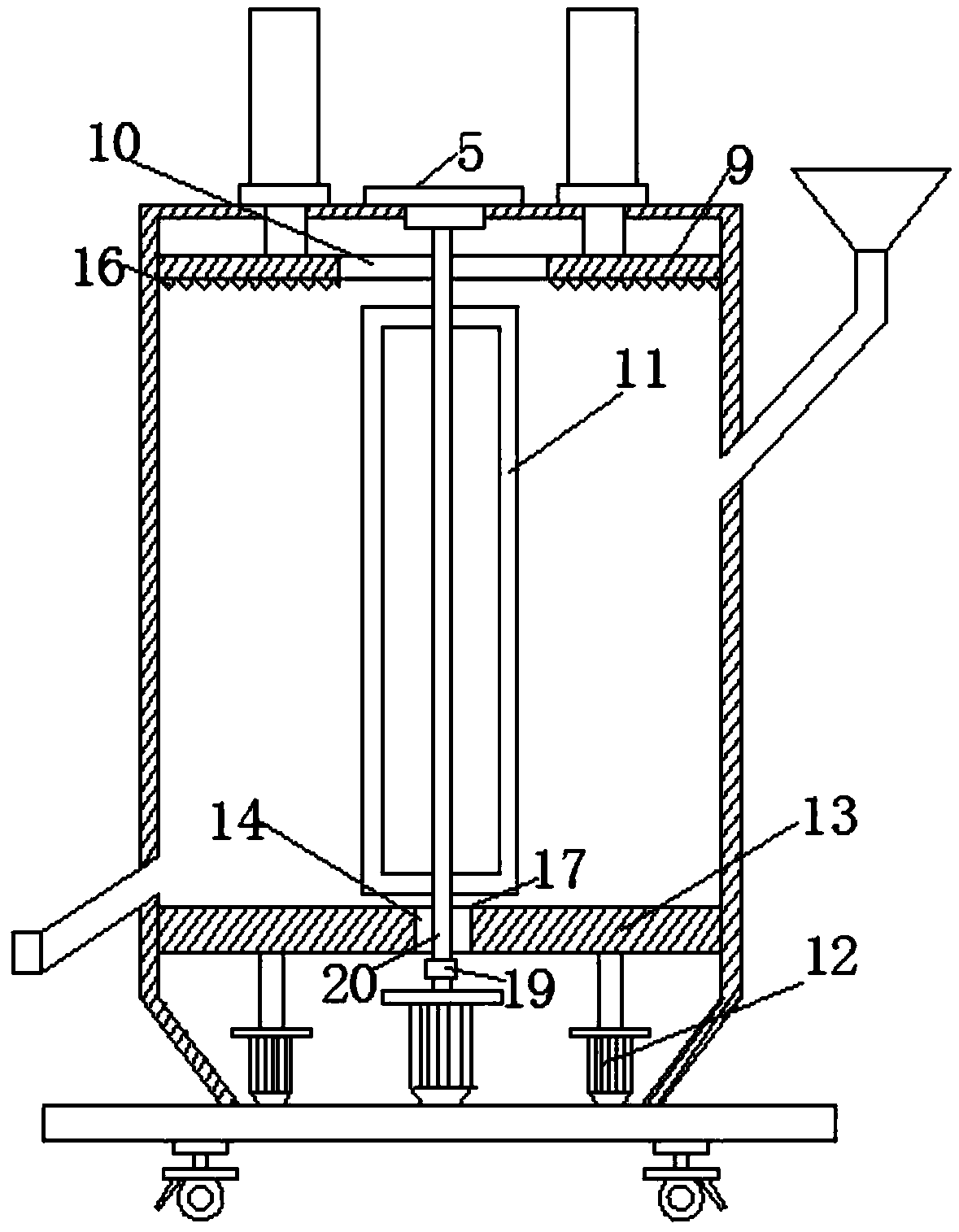

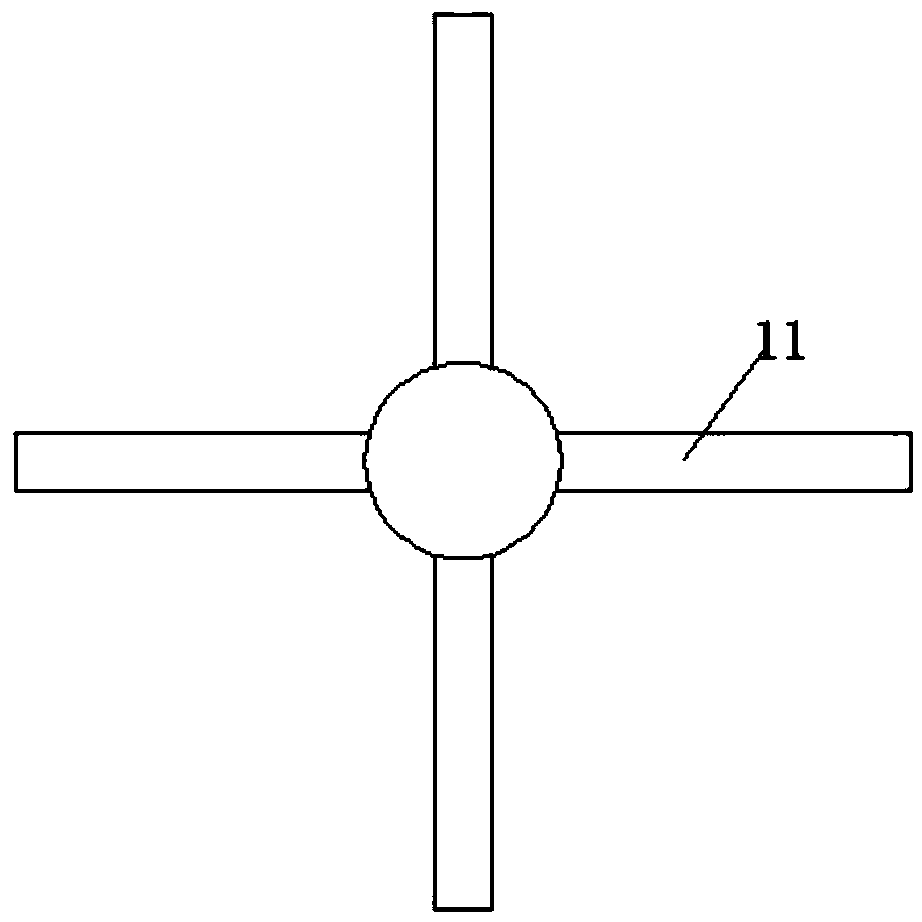

[0018] Such as Figure 1 to Figure 3 As shown, a feed processing and batching device for quickly mixing feed ingredients and ratios includes a base 1, a feed box 2 is installed on the upper surface of the base 1, and a discharge pipe 7 is fixedly installed on the left and right sides of the feed box 2, respectively. And feed pipe 3, the free end of described feed pipe 3 is welded with feed inlet 4, and the free end of described discharge pipe 7 is threadedly connected with discharge cover 8, and the upper surface of described feed box 2 is fixed Two groups of telescopic cylinders 6 are installed, the piston rod ends of the telescopic cylinders 6 are fixedly connected with an extruding plate 9, the middle part of the extruding plate 9 is provided with a first through hole 10, and the upper surface of the feed box 2 A bearing seat 5 is installed, and the beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com