Efficient oil-gas recovery adsorption tank regeneration device and method

A regeneration device and adsorption tank technology, which is applied in separation methods, filter regeneration, chemical instruments and methods, etc., can solve the problem of large processing capacity, the recovery of multi-substance mixed gas is not very applicable, and there is no multi-stage composite vacuuming method, etc. problems, to achieve the effect of low vacuum, stable airflow and large pumping capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

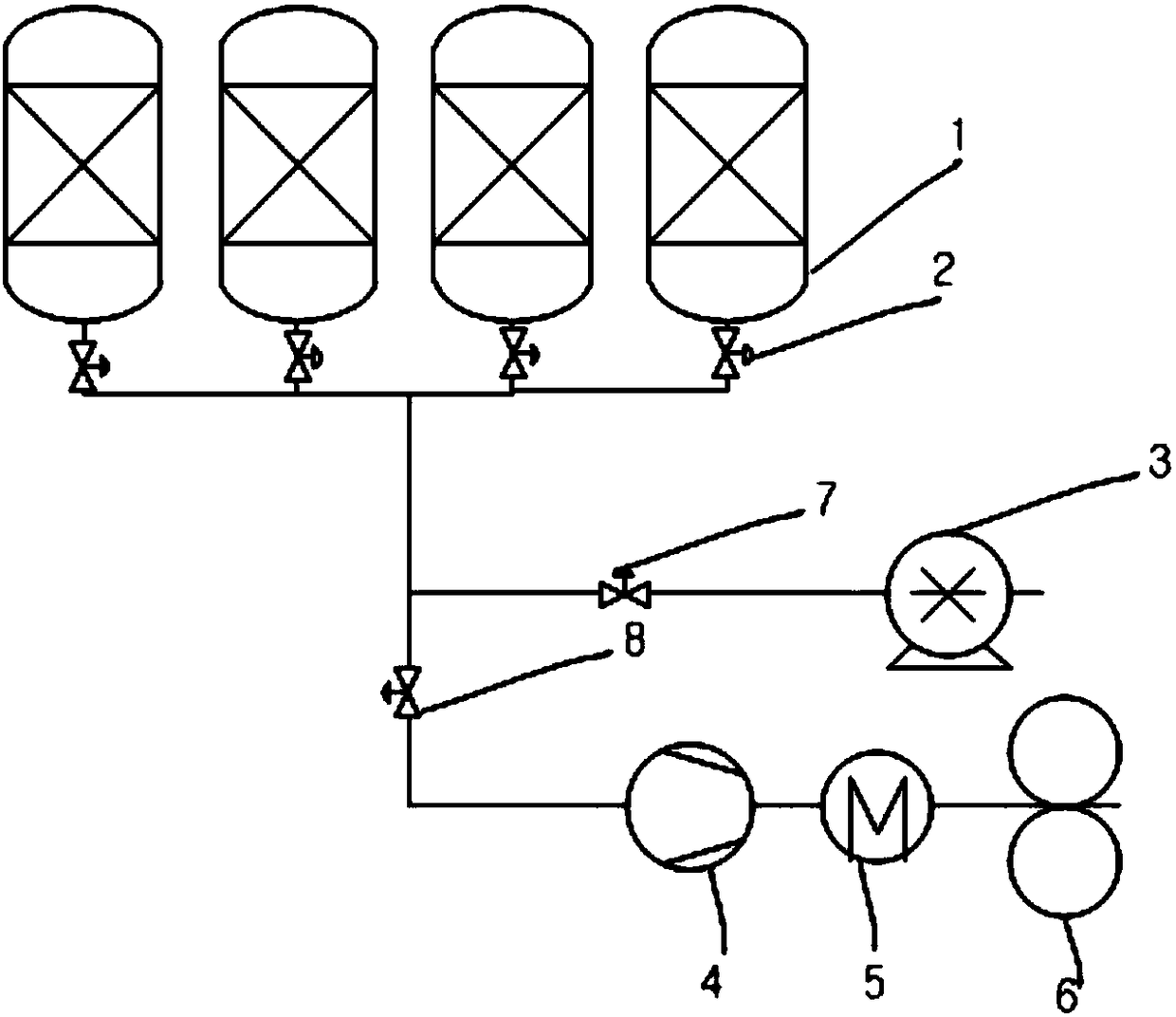

[0016] The invention provides a high-efficiency oil and gas recovery adsorption tank regeneration device, such as figure 1 As shown, the device has low operating cost and stable operation.

[0017] Such as figure 1 The high-efficiency oil and gas recovery adsorption tank regeneration device shown includes a liquid ring vacuum unit 3, a Roots vacuum unit 4, a screw vacuum unit 6, a Roots vacuum unit 4 and a screw vacuum unit 6 connected to four adsorption tanks 1 through pipelines. connected in series and in parallel with the liquid ring vacuum unit 3; the outlet of the adsorption tank 1 is provided with an analytic valve 2, the pipeline between the liquid ring vacuum unit 3 and the adsorption tank 1 is provided with a program-controlled valve 17, the Roots vacuum unit 4 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com