A pneumatic-compression composite forming method for rectangular cross-section hollow parts of hard-to-deform materials with rounded corners r≤2t

A technology of rectangular cross-section and composite forming, which is applied in the field of forming of rectangular cross-section hollow components of difficult-to-deform materials, can solve the problems of poor inner profile precision, low profile precision, uneven wall thickness, etc., so as to improve precision and reliability. , the effect of reducing the length of the weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

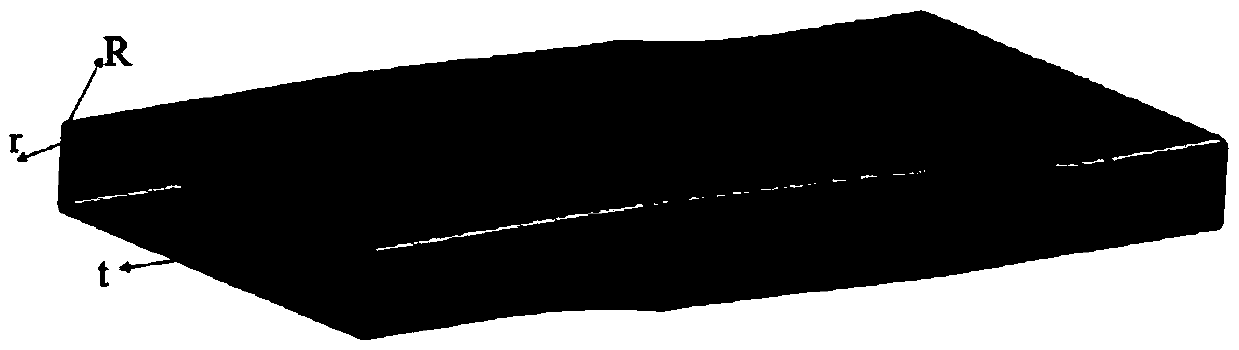

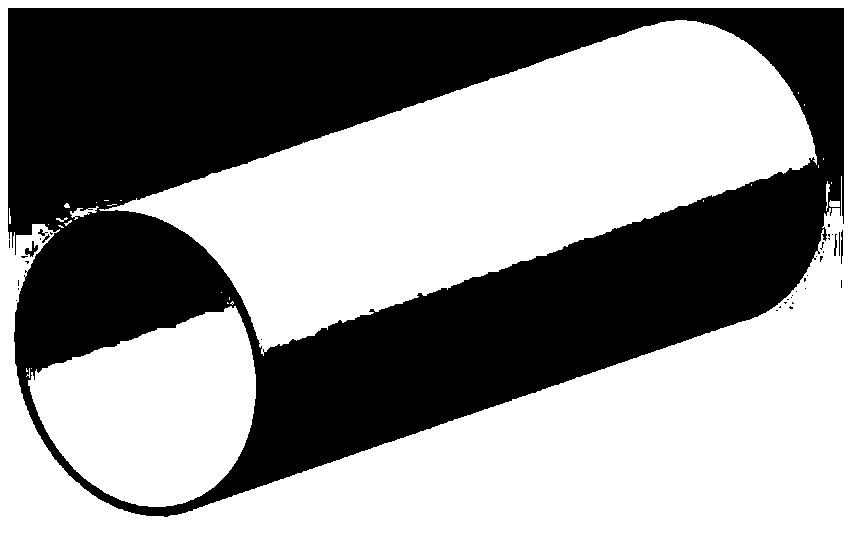

[0022] Specific implementation mode 1: This implementation mode is an air pressure-molding composite forming method for a hollow part with a rectangular cross-section made of a hard-to-deform material with rounded corners R≤2t, which is specifically completed according to the following steps:

[0023] 1. Preforming: Preheat the mold to temperature T 1 ,T 1 is the forming temperature of the hard-to-deform material tube blank, then put the hard-to-deform material tube blank into the mold, and heat the hard-to-deform material tube blank to T 1 , at temperature T 1 Then use the mold to mold the hard-to-deform material tube blank into the preform shape to obtain the preform; the wall thickness of the difficult-to-deform material tube blank is t, the outer diameter of the hard-to-deform material tube blank is D, and the height of the preform is for h 1 , and 0.1D≤h 1 ≤0.9D;

[0024] 2. Air pressure forming: seal both ends of the preform with a sealing structure, and then pass g...

specific Embodiment approach 2

[0027] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the hard-to-deform material tube blank described in step 1 is a titanium alloy round-section tube blank or an intermetallic compound round-section tube blank. Others are the same as the first embodiment.

specific Embodiment approach 3

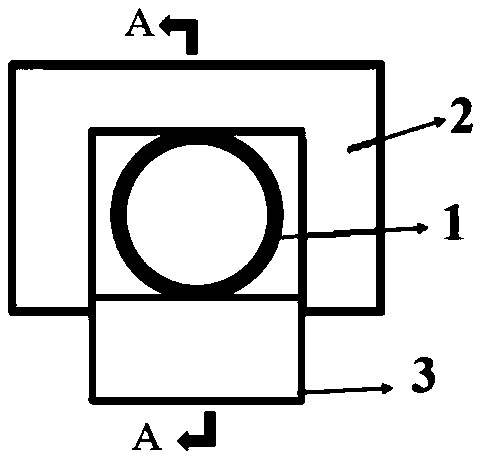

[0028] Specific implementation mode three: combination image 3 , Image 6 with 7 As shown, the difference between this embodiment and one of the specific embodiments 1 or 2 is: the mold described in step 1 is composed of an upper mold 2 and a lower mold 3, and the upper mold 2 and the lower mold 3 are preheated to a temperature T 1 , and then put the difficult-to-deform material tube blank 1 into the mold cavity formed by the upper mold 2 and the lower mold 3, and heat the difficult-to-deform material tube blank 1 to the temperature T through the heat conduction of the mold 1 , at temperature T 1 Next, the upper mold 2 is used to move downward to mold the difficult-to-deform material tube blank 1 into a preform shape to obtain a preform. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com