Square can empty can production line and production method

A production line and empty tank technology, which is applied to hollow objects, safety equipment, applications, etc., can solve problems such as low production efficiency, and achieve the effects of improving production efficiency, improving use efficiency and reducing idle rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

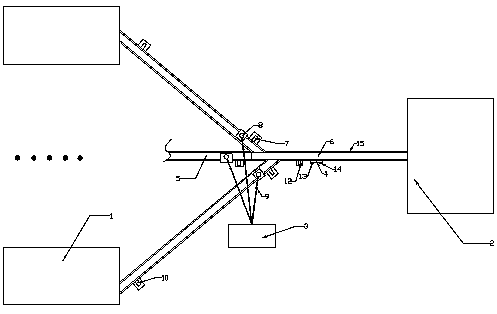

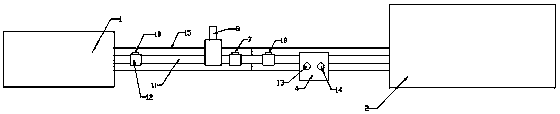

[0033] This embodiment, as a preferred embodiment of the present invention, discloses a square can empty can production line, its specific distribution diagram is as follows: figure 1 As shown, it includes 2 square can body assembly machines 1, a can lid sealing machine 2, a control air source 3 and a controller 4, the outlet end of the square can body assembly machine 1 is provided with a branch conveyor 5, and the can lid The inlet end of the sealing machine 2 is provided with a main conveyor 6, and the branch conveyor 5 communicates with the main conveyor 6; both sides of the branch conveyor 5 and the main conveyor 6 are provided with guardrails 15 and chutes 11. The distance between the guardrails 15 on the same conveyor is 1.1 times the width of the can body to ensure that the cans on the conveyor are arranged neatly; there are multiple mounting seats 12 slidingly arranged in the chute 11; A safety sensor 10 is arranged on the safety seat 12 at the inlet end of the convey...

Embodiment 2

[0036] In this embodiment, as another preferred embodiment of the present invention, it is provided with 5 square can body assembly machines 1 and a can lid sealing machine 2 in total, and the guard rails of the branch line conveyor 5 and the main conveyor 6 The spacing between 15 is 1.3 times of the width of the can body of the can; the detection sensor 7 is located on the left side of the control cylinder 8 .

Embodiment 3

[0038] This embodiment, as another preferred embodiment of the present invention, discloses a control method for a production line of square cans and empty cans, which includes the following steps:

[0039] A. Set the starting time interval T of the detection sensor on each branch conveyor to 10s and the effective detection time T of the safety sensor to 8s through the controller;

[0040]B. Set the opening sequence of the control cylinders on each branch conveyor through the controller. After the setting is completed, the controller will first open the control cylinder on the branch conveyor, retract its piston rod, and at the same time retract all the piston rods of the remaining control cylinders. freed;

[0041] C. Start all equipment and start timing. When the time T is over, start the detection sensor on the branch conveyor that was opened first. When the detection sensor is blocked by the tank body, it will transmit a control signal to the controller, and the controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com