Constant-temperature preparation method of semi-solid structural slurry of die-casted aluminum alloy billet

An aluminum alloy and semi-solid technology, which is applied in the field of warm semi-solid tissue slurry preparation, can solve the problems of high energy consumption and expensive production equipment for thixotropic forming slurry, and achieve efficient transformation process and shape, and reduced deformation power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

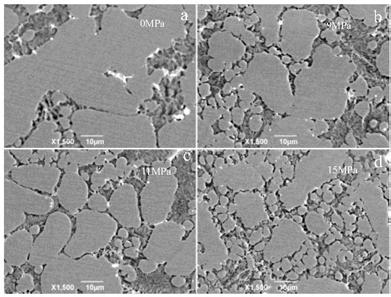

[0031] Step 1: Pour aluminum alloy molten metal at a temperature of 730°C to 750°C into the die-casting machine, adjust the first-speed switching position of the die-casting machine to 355mm to 365mm, the first-speed speed to 35cm / s to 45cm / s, and the second-speed switching position to 45mm ~55mm, 2nd speed 85cm / s~95cm / s;

[0032] Adjust the injection pressure of the die-casting machine to 0MPa for pouring and die-casting to obtain an aluminum alloy die-casting ingot;

[0033] Step 2: Place the alloy die-casting ingot in a resistance furnace, and at an isothermal temperature of 605°C to 615°C, select the isothermal time to be 4min to 9min, 9min to 15min, 15min to 20min, 25min to 30min or 58min to 63min to obtain half Solid aluminum alloy paste.

Embodiment 2

[0035] Step 1: Pour aluminum alloy molten metal at a temperature of 730°C to 750°C into the die-casting machine, adjust the first-speed switching position of the die-casting machine to 355mm to 365mm, the first-speed speed to 35cm / s to 45cm / s, and the second-speed switching position to 45mm ~55mm, 2nd speed 85cm / s~95cm / s;

[0036] Adjust the injection pressure of the die-casting machine to 8-10MPa for pouring and die-casting to obtain an aluminum alloy die-casting ingot;

[0037] Step 2: Place the alloy die-casting ingot in a resistance furnace, and at an isothermal temperature of 605°C to 615°C, select the isothermal time to be 4min to 9min, 9min to 15min, 15min to 20min, 25min to 30min or 58min to 63min to obtain half Solid aluminum alloy paste.

Embodiment 3

[0039] Step 1: Pour aluminum alloy molten metal at a temperature of 730°C to 750°C into the die-casting machine, adjust the first-speed switching position of the die-casting machine to 355mm to 365mm, the first-speed speed to 35cm / s to 45cm / s, and the second-speed switching position to 45mm ~55mm, 2nd speed 85cm / s~95cm / s;

[0040] Adjust the injection pressure of the die-casting machine to 10-13 MPa for pouring and die-casting to obtain an aluminum alloy die-casting ingot;

[0041] Step 2: Place the alloy die-casting ingot in a resistance furnace, and at an isothermal temperature of 605°C to 615°C, select the isothermal time to be 4min to 9min, 9min to 15min, 15min to 20min, 25min to 30min or 58min to 63min to obtain half Solid aluminum alloy paste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com