Full-automatic dual-grinding-head four-station diamond saw blade edging machine

A diamond saw blade and double grinding head technology, applied in metal sawing equipment, manufacturing tools, metal processing equipment and other directions, can solve the problems of low degree of automation, long cutting time, low cutting precision, etc. Accurate control, high degree of automation, good quality of cutting edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

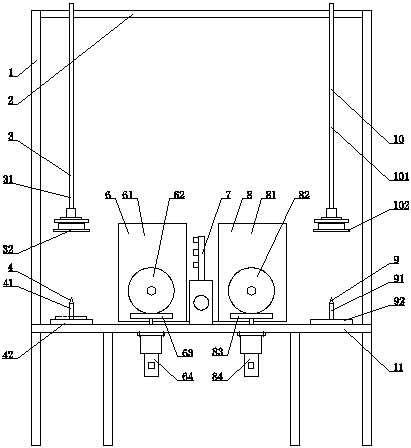

[0007] See figure 1 , The present invention includes a frame 1, the middle part of the frame 1 is provided with a base 11, and also includes a guide rod 2, a front grinding and loading device 3, a loading tray 4, a front edge cutting device 6, and a turning mechanism 7 , Reverse edge opening device 8, blanking plate 9, reverse grinding and loading and unloading device 10, the front grinding and loading device 3 includes a front grinding and loading cylinder 31 and a front grinding and loading electromagnetic chuck 32, the upper The tray 4 includes a feeding positioning column 41 and a feeding tray 42. The front edge sharpening device 6 includes a front edge sharpening grinding head 61, a front edge sharpening wheel 62, a front edge sharpening worktable 63, and a front edge sharpening motor 64. , The reverse edge sharpening device 8, the reverse sharpening grinding head 81, the reverse sharpening grinding wheel 82, the reverse sharpening worktable 83 and the reverse sharpening m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com