Latex preparation process

A technology of latex and latex particles, which is applied in the field of preparing latex emulsion and toner, and can solve problems such as difficulty in achieving batch consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

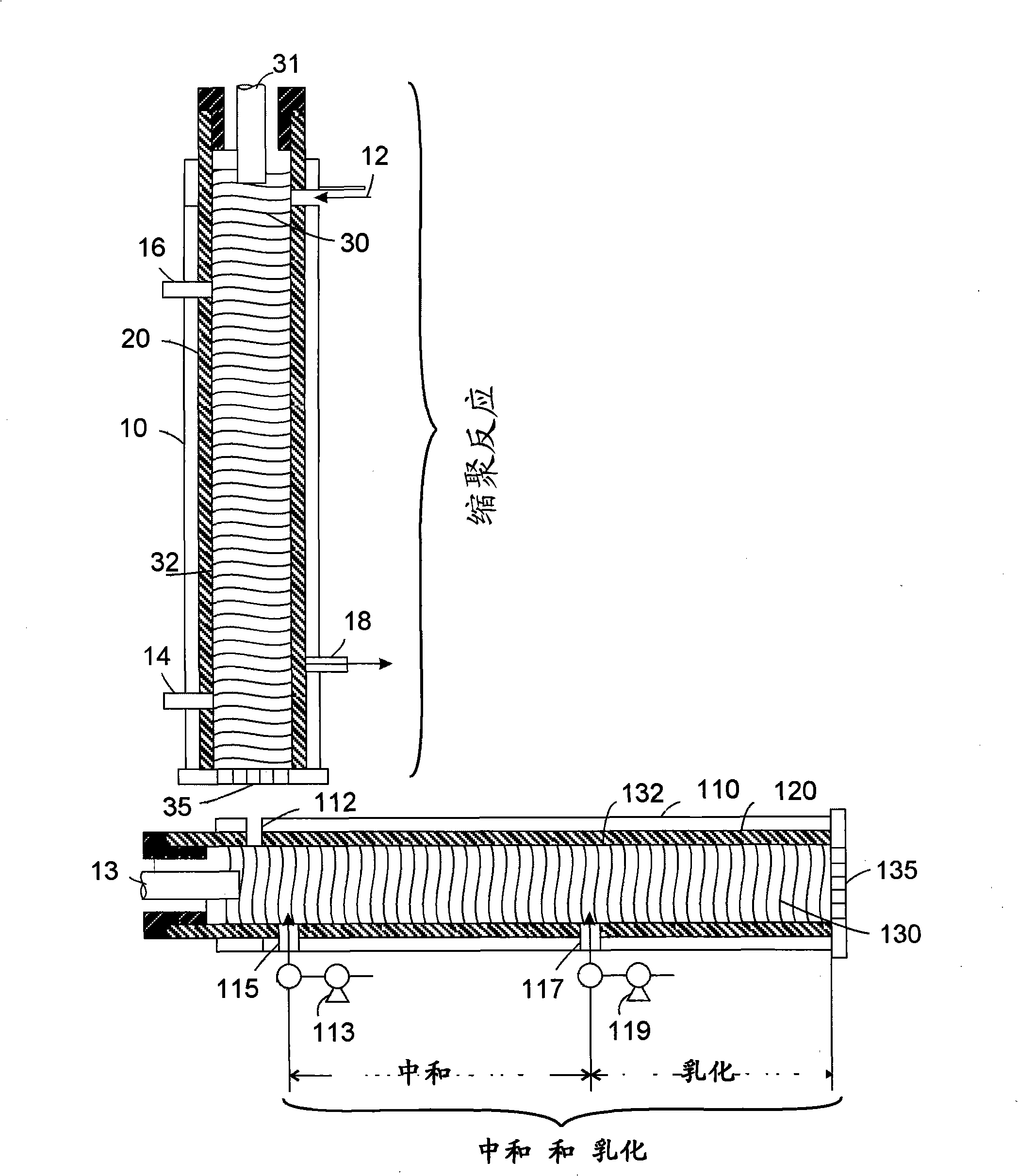

[0107] use figure 1 The extruder depicted in was used to continuously prepare solvent-free linear amorphous polyester emulsions.

[0108] Linear propoxylated bisphenol A fumarate polyester resin GTUF (commercially available from Kao Corporation, Japan) was charged into the extruder at a rate of about 2 lbs / hour, and deionized Water, sodium bicarbonate, and alkyl diphenyl ether disulfonate ionic surfactant (commercially available as DOWFAX® from The Dow Chemical Company) TM 2A1) in water, independently pumped into the extruder downstream of the extruder at a rate of about 100 g / min, the extruder rotating at about 900 rpm at a temperature of about 20°C. The formulations are summarized in Table 1 below:

[0109] Table 1

[0110] Linear Polyester (GTUF)

29.28%

0.73%

Dowfax 2A1

1.76%

Deionized water

68.23%

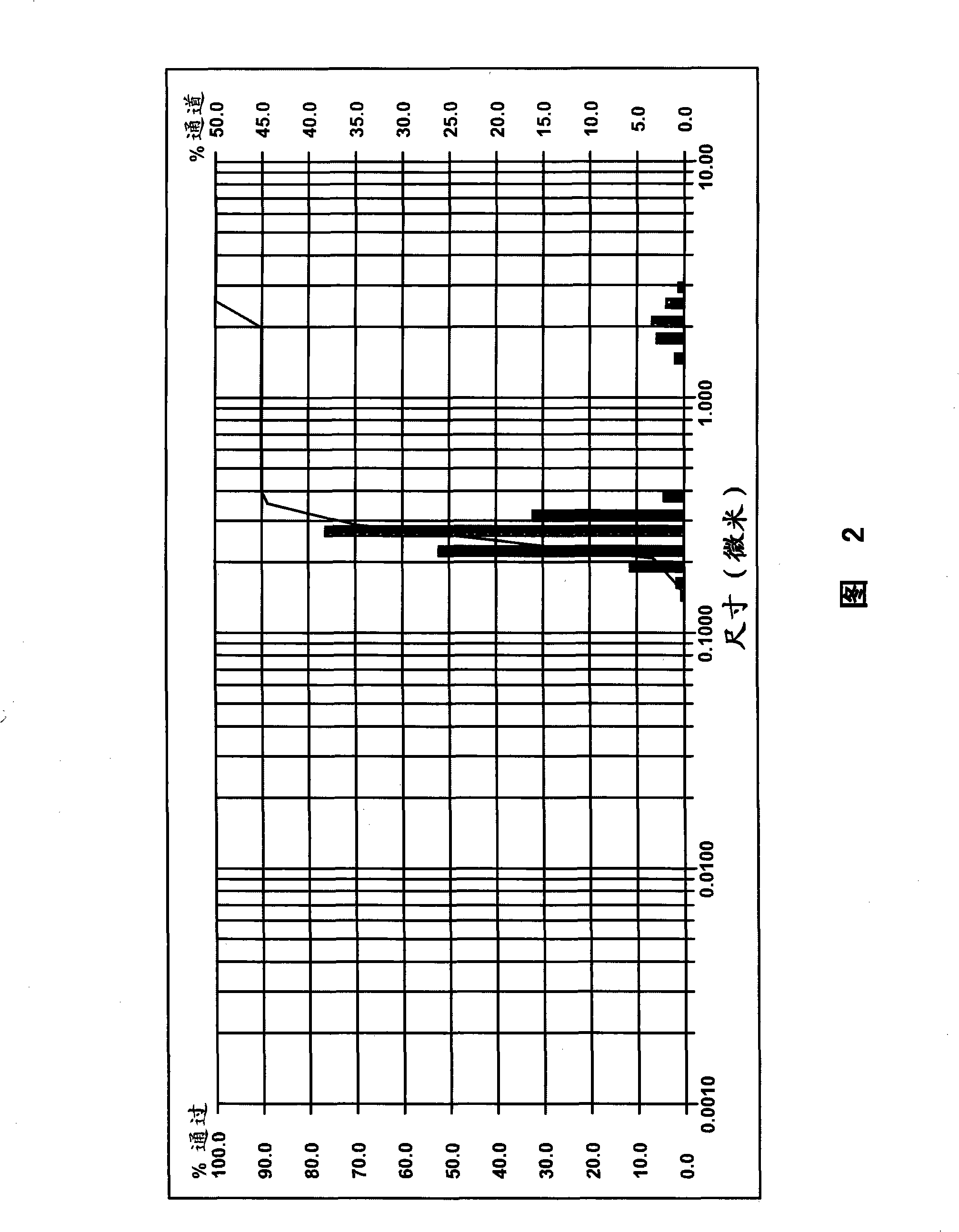

[0111] The emulsified particles were collected at the end of the extruder and the particle...

Embodiment 2

[0122] use figure 1 The extruder depicted in was used to continuously prepare solvent-free linear crystalline polyester emulsions.

[0123] A3C crystalline polyester (a proprietary blend of 1,4-butanediol, fumaric acid, and adipic acid obtained from Kao Corporation (Japan)) was fed to the extruder at a rate of about 4 lbs / hour , and will contain deionized water, sodium bicarbonate and DOWFAX TM An aqueous solution of 2A1 (alkyldiphenyl ether disulfonate anionic surfactant from The Dow Chemical Company) was pumped into the extruder downstream of the extruder at a rate of about 100 g / min, and the extruder was running at about 1100 rpm. Speed rotation, temperature about 20°C. The formulations are summarized in Table 3 below:

[0124] table 3

[0125] Crystalline Polyester (A3C)

29.28%

0.73%

Dowfax 2A1

1.76%

Deionized water

68.23%

[0126] The emulsified particles were collected at the end of ...

Embodiment 3

[0132] A high molecular weight amorphous polyester resin comprising 1,4-benzenedicarboxylic acid and 1,3-dihydro-1,3-dioxo-5 was emulsified in a multi-screw extruder -isobenzofuran carboxylic acid, 3-(dodecen-1-yl)dihydro-2,5-furandione, α,α′-[(1-methylethylene)di-4,1 -phenylene]bis[Ω-hydroxypoly(oxy-1,2-ethanediyl)] and α,α′-[(1-methylethylene)bis-4,1-phenylene]bis Conjugation of [Ω-hydroxypoly[oxy(methyl-1,2-ethylenediyl)]]. The polyester resin 1 was charged into the extruder at a rate of about 6 lbs / hour, and an ionic surfactant (commercially available from Tayca Corporation (Japan)) was injected downstream at a rate of about 166 grams / minute, Next, about 10% NaOH solution was injected at a rate of about 66 g / min. The emulsion was processed in the extruder at a screw speed of about 500 rpm and a barrel temperature of about 100°C.

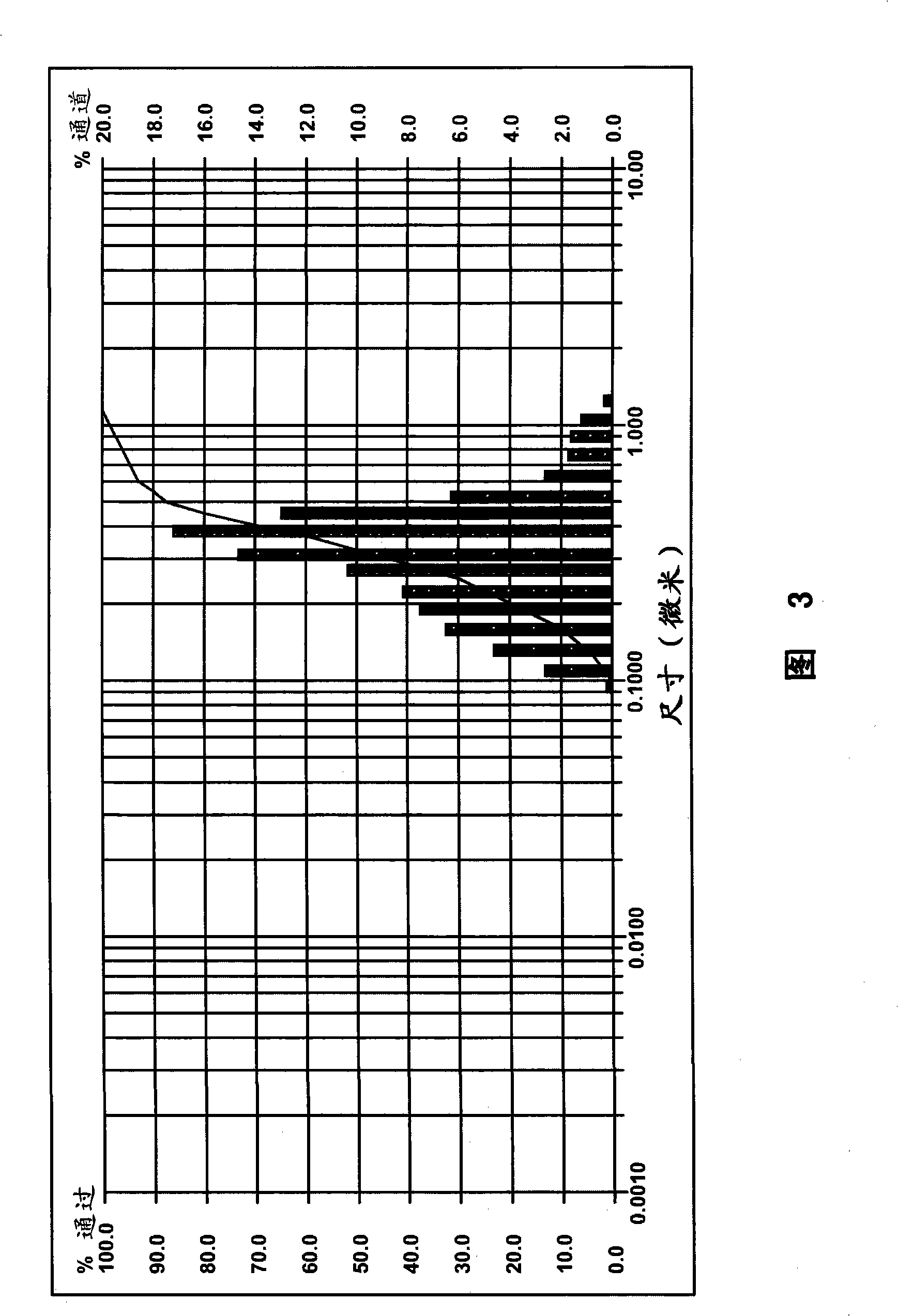

[0133] The emulsion particles were collected and the particle size and size distribution were measured as described in Example 1 above. Fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com