A processing device for rubber-plastic sealing composite material components

A technology of composite material components and processing devices, applied in metal processing and other directions, can solve the problems of rubber and plastic sealing and lubrication problems, such as the inability of high-end technology to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

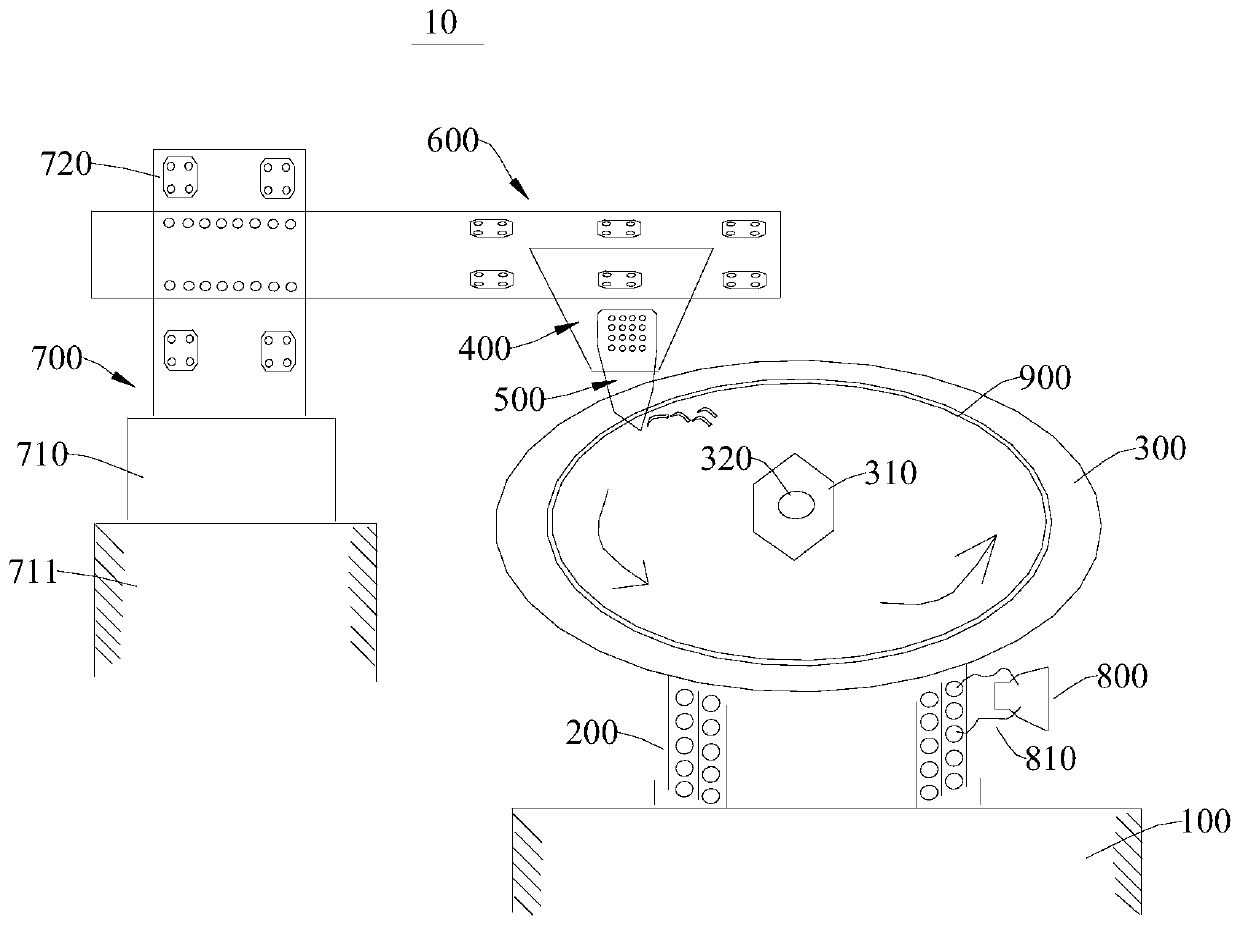

[0045] During the manufacturing process of the rubber-plastic sealing composite component 900, the rubber-plastic sealing material is prone to problems such as delamination, shrinkage, tearing damage, and severe tool wear. In the process, there were very few tests on the generation, development and evolution of the internal stress of the rubber-plastic seal manufacturing, which resulted in the poor performance of the rubber-plastic seal composite component 900 in terms of wear resistance, corrosion resistance, friction reduction and life extension, and it was difficult to achieve strong alternating temperature. The service life and reliability of rubber and plastic seals of high-end equipment under the environment of strong vibration, high pressure, and high speed cannot establish a quantitative model for the state transition of the soft friction and lubrication area of the friction pair.

[0046] The applicant found that the reason is that the experimental data of the rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com