A polyurethane elastomer containing two kinds of heteroatoms in the hard segment, a modified polyurethane anti-corrosion peelable film and its preparation method and application

A polyurethane elastomer and heteroatom technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problems of inability to achieve anti-corrosion performance, inability to coat the film to prevent rust, etc., and achieve good peelability and Effects of anti-corrosion performance, excellent anti-corrosion, and excellent adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] refer to Figure 10 , a method for preparing a modified polyurethane anti-corrosion peelable film containing two kinds of heteroatoms in the hard segment of the present invention, comprising the following steps:

[0035]Step 1, in parts by mass, add 5-10 parts of organic acid to 95-190 parts of organic solvent absolute ethanol to prepare solution 1; add 5-10 parts of oxides with anti-corrosion function In the above solution 1, stir at 40-60°C for 4-8 hours at a stirring speed of 120-240r / min, filter and wash with organic solvent anhydrous ethanol several times, and dry at 30-100°C. The modified oxide is obtained; the added oxide is one or more of aluminum oxide, zinc oxide, iron oxide, ferric oxide, and silicon dioxide mixed in any proportion; the particle size of the modified oxide obtained is 200-800 mesh. The organic acid used is one or more of lauric acid, myristic acid, palmitic acid, stearic acid, oleic acid, arachidic acid and the like. Preferably, the amount ...

Embodiment 1

[0051] A method for preparing a modified polyurethane anti-corrosion peelable film containing two kinds of heteroatoms in the hard segment, comprising the following steps:

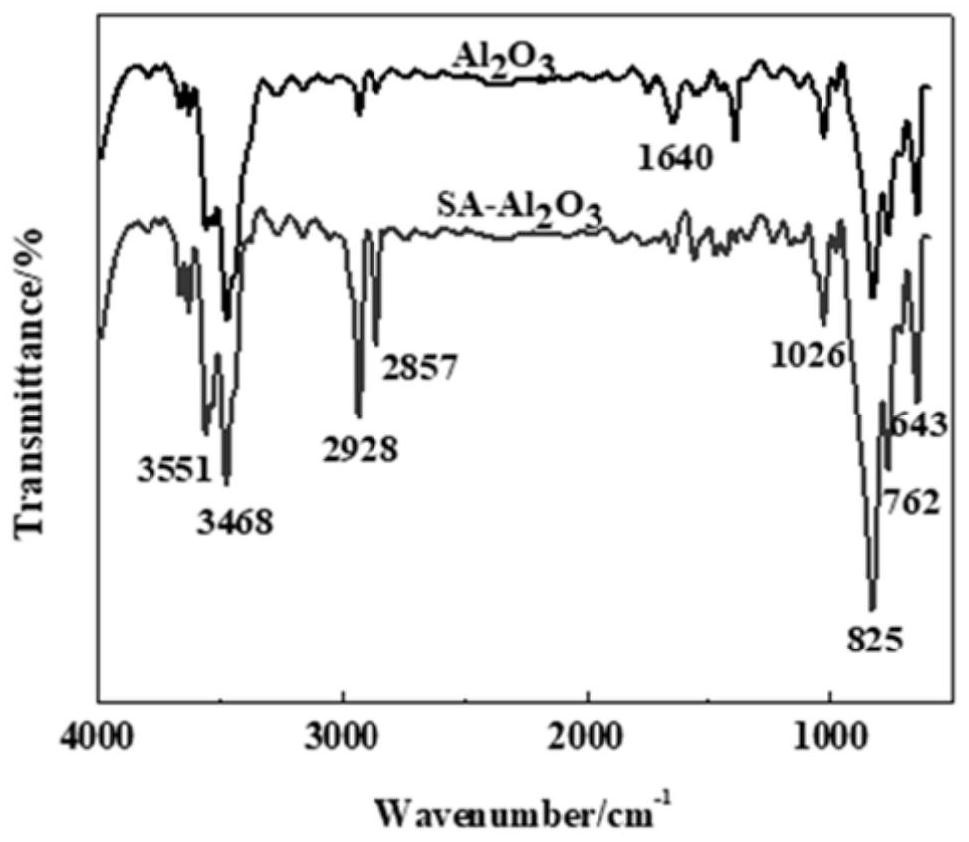

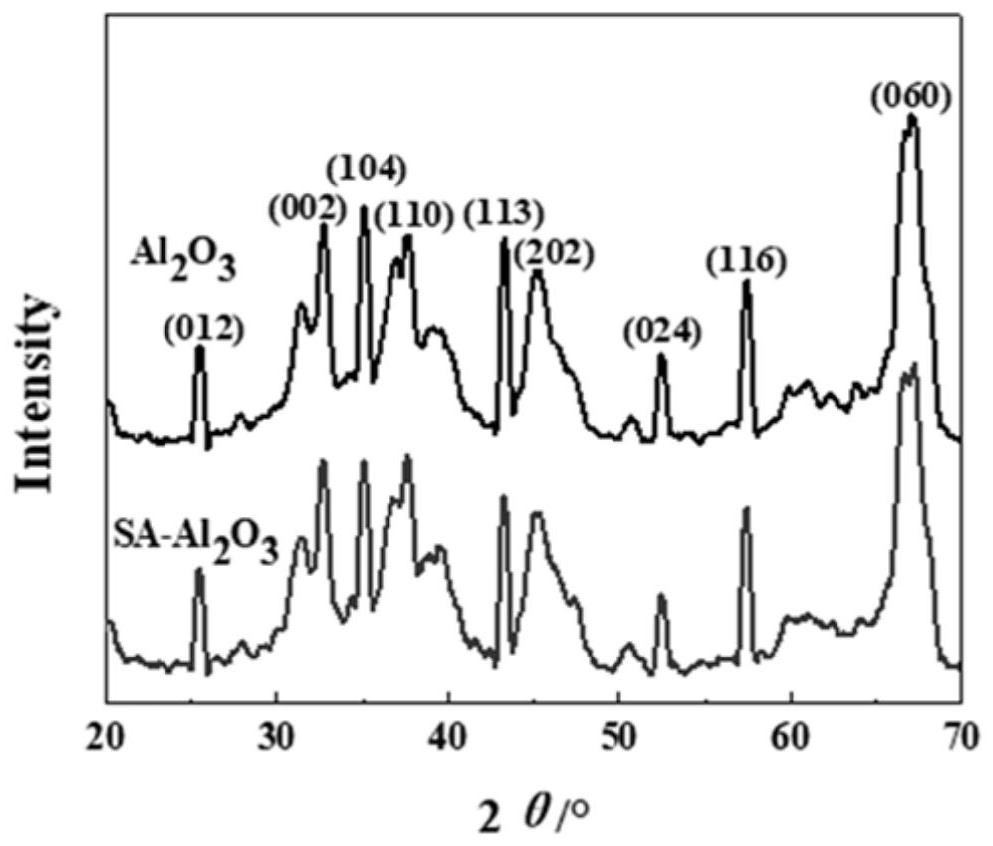

[0052] 1) In terms of parts by mass, add 5 parts of stearic acid to 95 parts of absolute ethanol to prepare solution 1; add 5 parts of alumina to the above solution 1, and stir at 60°C at 180r / min for 6h , filtered and washed several times with absolute ethanol, and dried at 60°C to obtain treated modified alumina;

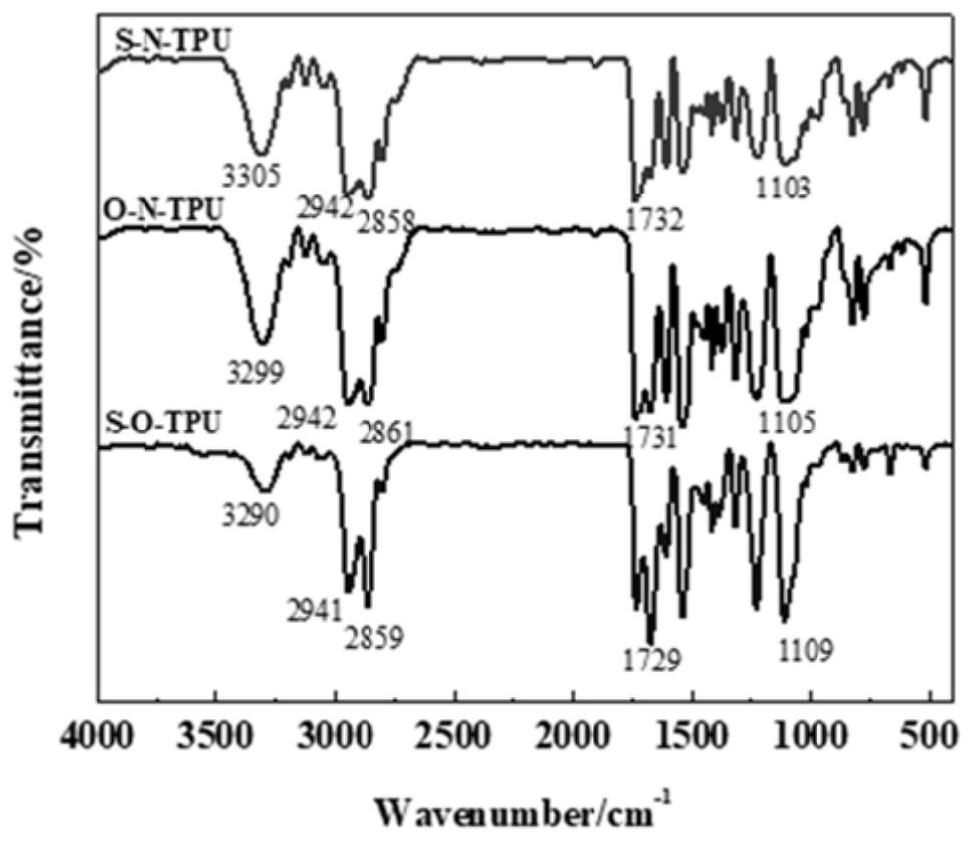

[0053]2) In terms of parts by mass, add 50 parts of purified polytetrahydrofuran ether glycol 1000 to 40 parts of molten 4,4'-methylene bis(phenylisocyanate), at 80°C 75r / min stirring for 0.5h to prepare a prepolymer; add 5 parts of 2,2'-thiobis-ethanol and 5 parts of N-methyldiethanolamine to the prepolymer, stir at 75r / min at 80°C for 1h, and Aging treatment at 110°C for 6 hours to obtain a polyurethane elastomer containing sulfur and nitrogen in the hard segment;

[0054] 3) In terms of ...

Embodiment 2

[0056] A method for preparing a modified polyurethane anti-corrosion peelable film containing two kinds of heteroatoms in the hard segment, comprising the following steps:

[0057] 1) In terms of mass parts, add 10 parts of oleic acid to 190 parts of acetone to prepare solution 1; add 10 parts of zinc oxide to the above solution 1, stir at 180r / min at 60°C for 6h, and use acetone Suction filtration and washing several times, drying at 60°C to obtain treated modified zinc oxide;

[0058] 2) In terms of parts by mass, add 50 parts of purified polytetrahydrofuran ether glycol 1000 to 40 parts of molten 4,4'-methylene bis(phenylisocyanate), at 80°C 75r / Min stirring for 0.5h to prepare a prepolymer; add 5 parts of 2,2'-thiobis-ethanol and 5 parts of diethylene glycol to the prepolymer, stir at 75r / min at 80°C for 1h, and Curing at 110°C for 6 hours to obtain a polyurethane elastomer containing sulfur and oxygen in the hard segment;

[0059] 3) In terms of parts by mass, add 20 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com