A wet-sprayable waterborne two-component polyurethane coating

A water-based two-component polyurethane coating technology, applied in polyurea/polyurethane coatings, antifouling/underwater coatings, coatings, etc., can solve problems such as low production efficiency and difficulty in wet spraying, and improve production efficiency , reduce excessive time, reduce the effect of production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

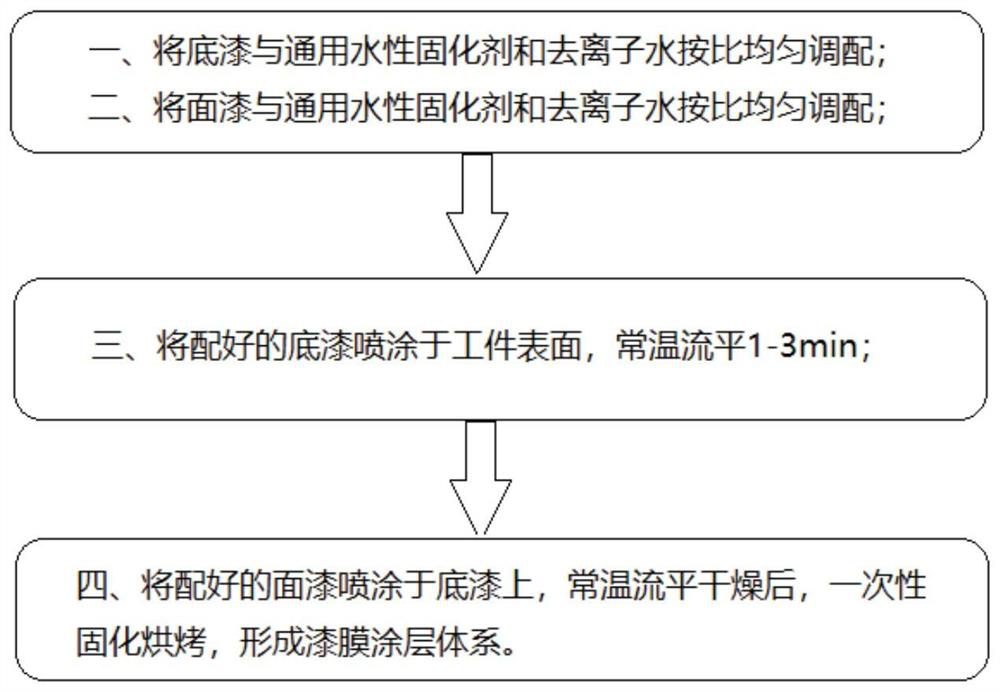

[0038] like Figure 1-Figure 3 As shown, a wet sprayable water-based two-component polyurethane coating of this embodiment, the coating includes a primer and a topcoat, wherein the primer and the topcoat are both added with hydrophilic fumed silica, and the primer is The added weight part of hydrophilic fumed silica is more than the added weight part of hydrophilic fumed silica in the topcoat. Specifically, in the present embodiment, the primer includes the following raw materials by weight:

[0039]

[0040]

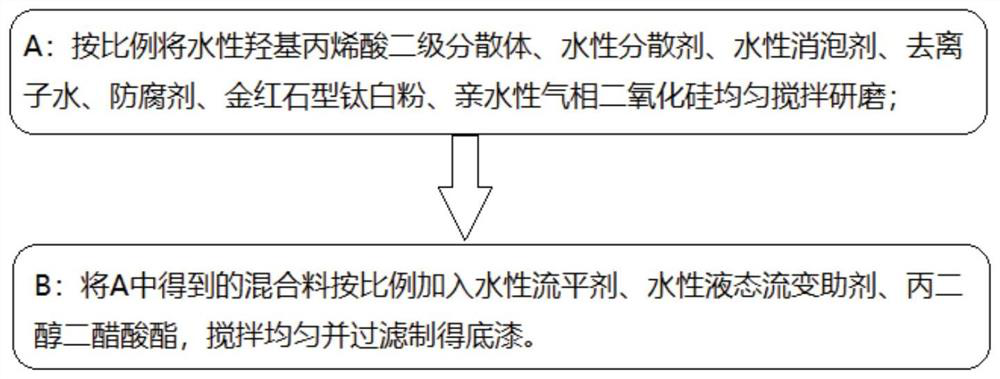

[0041] The preparation method of this primer in the present embodiment is as follows:

[0042] A, prepare the raw material according to the above-mentioned formula amount, stir the water-based hydroxyacrylic acid secondary dispersion under the condition of 300 rev / min, add 0.2-0.4 parts by weight pH value regulator (according to the selected secondary water-based hydroxyacrylic acid) under the stirring condition The pH value of the dispersion determines the addi...

Embodiment 2

[0057] A kind of wet-sprayable waterborne two-component polyurethane coating of the present embodiment, coating comprises primer and finish paint, is basically the same as embodiment 1, difference is, in the present embodiment, primer comprises the raw material of following weight portion:

[0058]

[0059]

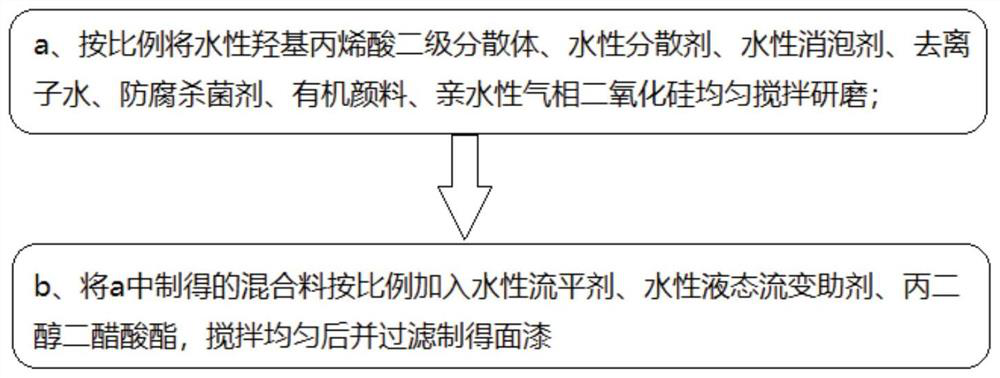

[0060] The preparation method of this primer in the present embodiment is as follows:

[0061] A. Prepare the raw materials according to the above formula, stir the water-based hydroxyacrylic acid secondary dispersion at 500 rpm, and add 0.2-0.4 parts by weight of a pH regulator under stirring conditions (according to the selected water-based hydroxyacrylic acid secondary dispersion). The PH value of the dispersion determines the amount added), water-based dispersant, water-based defoamer, deionized water, antiseptic and fungicide, rutile titanium dioxide, hydrophilic fumed silica. After stirring for 12 minutes under the condition of / minute, grind to a fineness of...

Embodiment 3

[0070] A kind of wet-sprayable waterborne two-component polyurethane coating of the present embodiment, coating comprises primer and finish paint, is basically the same as embodiment 1, difference is, in the present embodiment, primer comprises the raw material of following weight portion:

[0071]

[0072] The preparation method of this primer in the present embodiment is as follows:

[0073] A. Prepare the raw materials according to the above formula, stir the water-based hydroxyacrylic acid secondary dispersion at 700 rpm, and add 0.2-0.4 parts by weight of a pH regulator under stirring conditions (according to the selected water-based hydroxyacrylic acid secondary dispersion). The PH value of the dispersion determines the amount added), water-based dispersant, water-based defoamer, deionized water, antiseptic and fungicide, rutile titanium dioxide, hydrophilic fumed silica, after adding, the mixture is turned at 1200 rpm After stirring for 15 minutes under the condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com