A kind of application method of wet spray wet water-based two-component coating

A water-based two-component, wet-spraying technology, applied in antifouling/underwater coatings, polyurea/polyurethane coatings, devices for coating liquids on surfaces, etc., can solve problems such as low production efficiency and difficulty in wet spraying , to achieve the effect of improving production efficiency, reducing excessive time, and reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

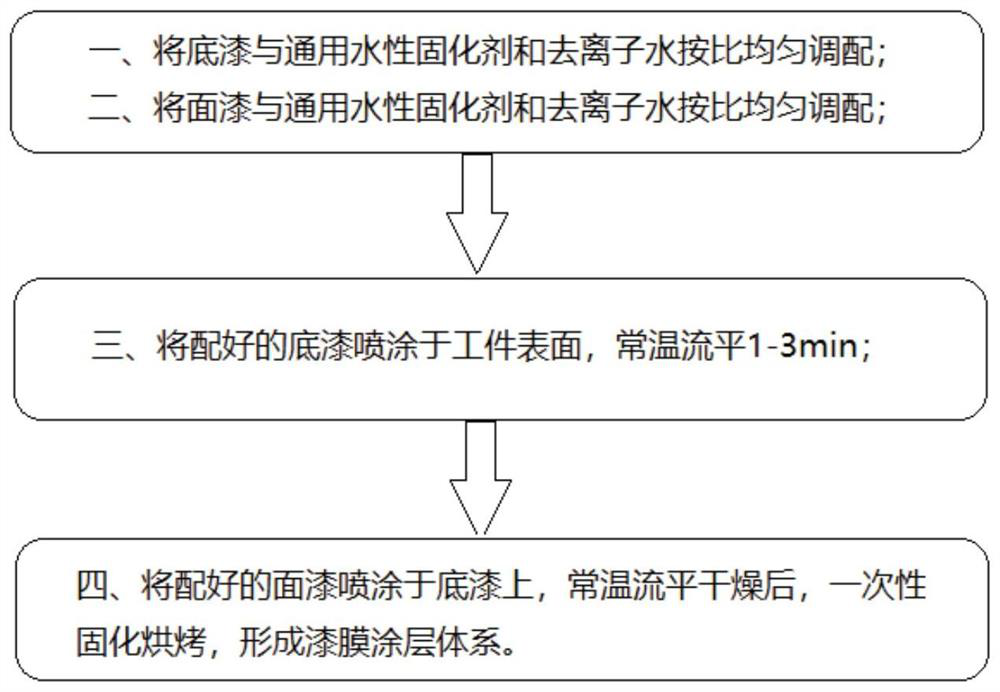

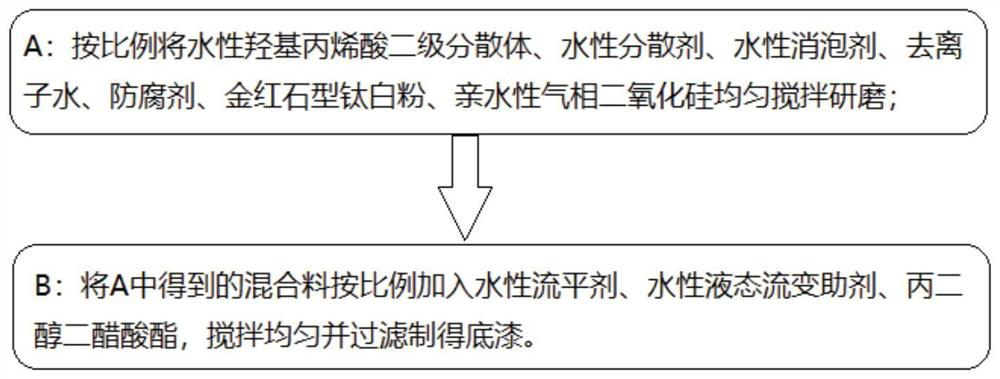

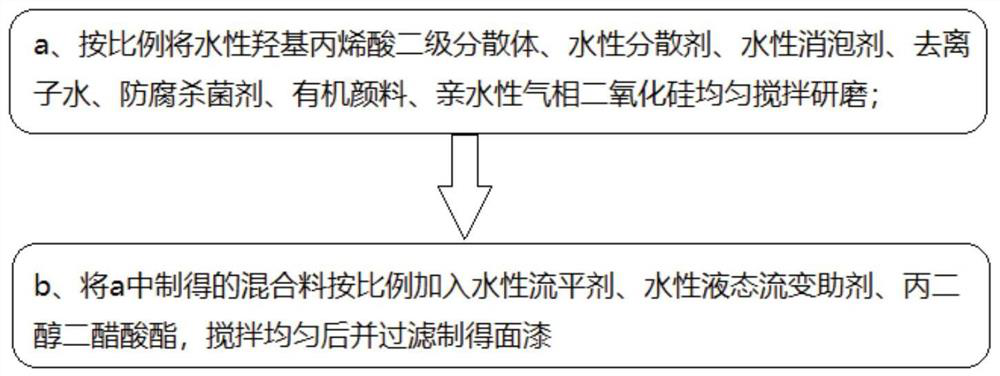

[0042] like Figure 1-Figure 3 As shown, the use method of a kind of wet spray wet water-based two-component paint of the present embodiment is carried out according to the following steps:

[0043] Step 1. Evenly mix the primer with the general water-based curing agent and deionized water at a ratio of 4:1:1;

[0044] Step 2: Evenly mix the topcoat with the general-purpose water-based curing agent and deionized water at a ratio of 3:1:1;

[0045] Step 3. Spray the prepared primer on the surface of the workpiece, and level it at room temperature for 1min;

[0046] Step 4: Spray the prepared topcoat on the primer layer, and level and dry the two coats at room temperature for 20 minutes; then cure and bake at 75° C. for 25 minutes to form a paint film coating system.

[0047] Wherein step 1 and step 2 have no sequence requirements, and the general water-based curing agent used is a water-based isocyanate curing agent, which specifically includes the following raw materials by we...

Embodiment 2

[0063] A method of using a wet-spray-wet water-based two-component paint of this embodiment, the primer is used together with the topcoat, specifically, the primer, the general-purpose water-based curing agent and deionized water are evenly prepared at 3:2:1; The topcoat, the general-purpose water-based curing agent and deionized water are evenly blended at a ratio of 2:1:1, and the prepared primer is sprayed on the surface of the workpiece. After leveling at room temperature for 3 minutes, the prepared topcoat is sprayed on the primer layer. The two coatings were leveled and dried at room temperature for 30 minutes; then cured and baked at 85°C for 35 minutes to form a paint film coating system.

[0064] The general water-based curing agent used is a water-based isocyanate curing agent, which specifically includes the following raw materials by weight: 40 parts of hydrophilic modified aliphatic polyisocyanate based on IPDI; 40 parts of hydrophilic modified aliphatic polyisocya...

Embodiment 3

[0078] A method of using a wet-spray-wet water-based two-component paint of this embodiment, the primer is used together with the topcoat, specifically, the primer, the general-purpose water-based curing agent and deionized water are evenly prepared at a ratio of 5:2:1; The topcoat, the general-purpose water-based curing agent and deionized water are evenly blended at a ratio of 4:2:1, and the prepared primer is sprayed on the surface of the workpiece. After leveling at room temperature for 2 minutes, the prepared topcoat is sprayed on the primer layer. The two coatings were leveled and dried at room temperature for 25 minutes; then cured and baked at 80°C for 30 minutes to form a paint film coating system.

[0079] The general water-based curing agent used is a water-based isocyanate curing agent, which specifically includes the following raw materials by weight: 50 parts of hydrophilic modified aliphatic polyisocyanate based on IPDI; 50 parts of hydrophilic modified aliphatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com