Pressure-sensitive conductive adhesive tape

A tape and adhesive layer technology, applied in the direction of pressure-sensitive film/sheet, adhesive, adhesive type, etc., can solve problems such as inability to reach and increase pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

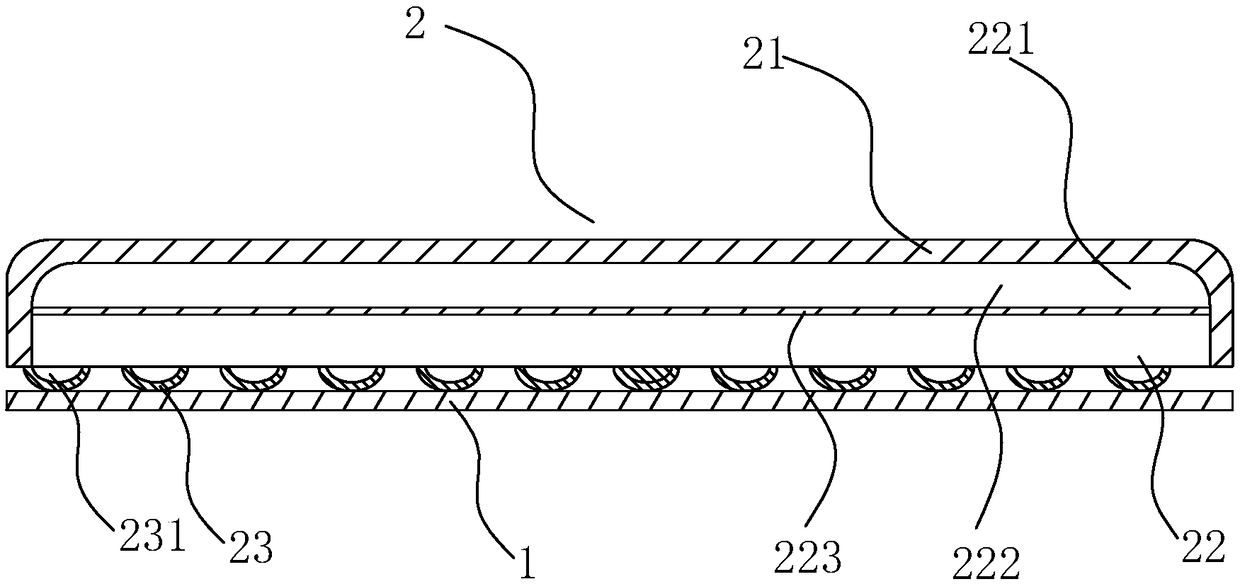

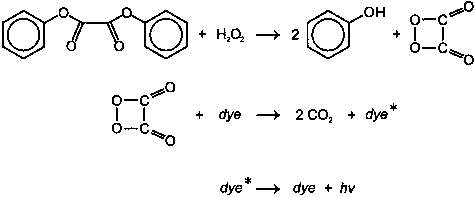

[0033] A pressure sensitive conductive tape such as figure 1 As shown, it includes an adhesive layer 1 and a release material layer 2. The release material layer 2 includes a flexible middle layer 21 and a force-bearing light-emitting layer 22 therein. The flexible hollow layer 21 can be made of PET, PVC or other plastics with good properties. resin; the flexible hollow layer 21 is provided with a glass membrane 223, and the flexible hollow layer 21 is separated into an upper hollow layer 221 and a lower hollow layer 222 by the glass membrane 223, wherein the upper hollow layer 221 is filled with a fluorescent agent, and the lower hollow layer 222 is filled with a fluorescent agent. Filled with an activator; the fluorescer uses fluorescent dye and diphenyl oxalate, and the activator uses hydrogen peroxide. In order to make the fluorescer and the activator react better, a thickener can be added to the fluorescer and the activator.

[0034] Such as figure 1 As shown, the adhesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com