Method of converter steelmaking through limestone

A converter steelmaking and limestone technology, which is applied in the manufacture of converters and the improvement of process efficiency, can solve the problems of difficult slag melting, less ore addition, serious slag back-drying, etc., shortening the smelting time and reducing the amount of converter slag Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

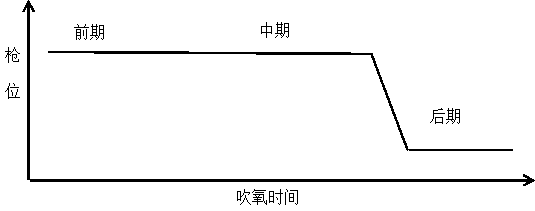

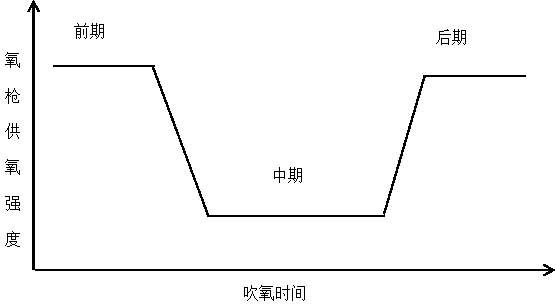

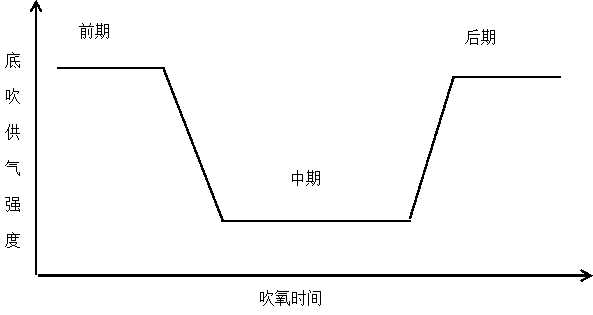

[0034] In a converter with a nominal capacity of 350 tons, the amount of limestone accounts for 64.6% of the total lime amount, the metal material is 91.7% of molten iron, and 9.3% of scrap steel. The amount of 26.71kg / ton of steel is added, and the limestone is added all at once after the oxygen lance is successfully ignited. The position of the lance in the early stage of blowing is adjusted within a certain range according to the smelting situation. The position of the oxygen lance H=(47~50)d 喉 The oxygen supply intensity of the oxygen lance is 2.85Nm3 / (t.min), and the intensity of the bottom blowing gas supply is 0.06Nm3 / (t.min). After 6 minutes of oxygen blowing, the position of the lance is adjusted within a certain range according to the smelting situation. Oxygen lance position H=(45~46)d 喉 The oxygen supply intensity of the oxygen lance is 2.58Nm3 / (t.min), the gas supply intensity of the bottom blowing is 0.045Nm3 / (t.min), and after 11 minutes of oxygen blowing, the p...

Embodiment 2

[0036] In a converter with a nominal capacity of 350 tons, the amount of limestone accounts for 22.2% of the total lime amount, the metal material is 86.5% of molten iron, and 13.5% of scrap steel. The amount of 11.3kg / ton of steel is added, and the limestone is added all at once after the oxygen lance is successfully ignited. The position of the lance in the early stage of blowing is adjusted within a certain range according to the smelting situation. The position of the oxygen lance H=(48~50)d 喉 Change within the range, the oxygen supply intensity of the oxygen lance is 2.89Nm3 / (t.min), the gas supply intensity of the bottom blowing is 0.05Nm3 / (t.min), after 6.5min of oxygen blowing, the position of the lance is adjusted within a certain range according to the smelting situation , oxygen lance position H=(46~48)d 喉 Change within the range, the oxygen supply intensity of the oxygen lance is 2.4Nm3 / (t.min), the gas supply intensity of the bottom blowing is 0.042Nm3 / (t.min), af...

Embodiment 3

[0038] In a converter with a nominal capacity of 350 tons, the amount of limestone accounts for 100% of the total amount of lime, the metal material is 92.1% of molten iron, 7.9% of scrap steel, the temperature of the molten iron into the furnace is 1445°C, and the silicon content of the molten iron into the furnace is 0.48%. The amount of 38kg / ton steel is added, and the limestone is added in three times. The amount of limestone added for the first time accounts for 57.1% of the total limestone. After oxygen blowing for 2 minutes, the limestone is added for the second time. Limestone accounts for 21.5% of the total amount of limestone, and oxygen is blown for 1.5 minutes Finally, put in the remaining limestone, and adjust the lance position in the early stage of blowing within a certain range according to the smelting situation. The oxygen lance position H=(49~50)d 喉 Change within the range, the oxygen supply intensity of the oxygen lance is 2.76Nm3 / (t.min), the intensity of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com