A steel structure connector filled with pre-fracture warning rods

A technology for steel structures and connectors, applied in building structures, mechanical visible signals, buildings, etc., can solve problems such as failure to detect in time, prolong the service life of steel structures, hidden safety hazards, etc., and achieve easy viewing, strong warning effects, and improved Follow-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

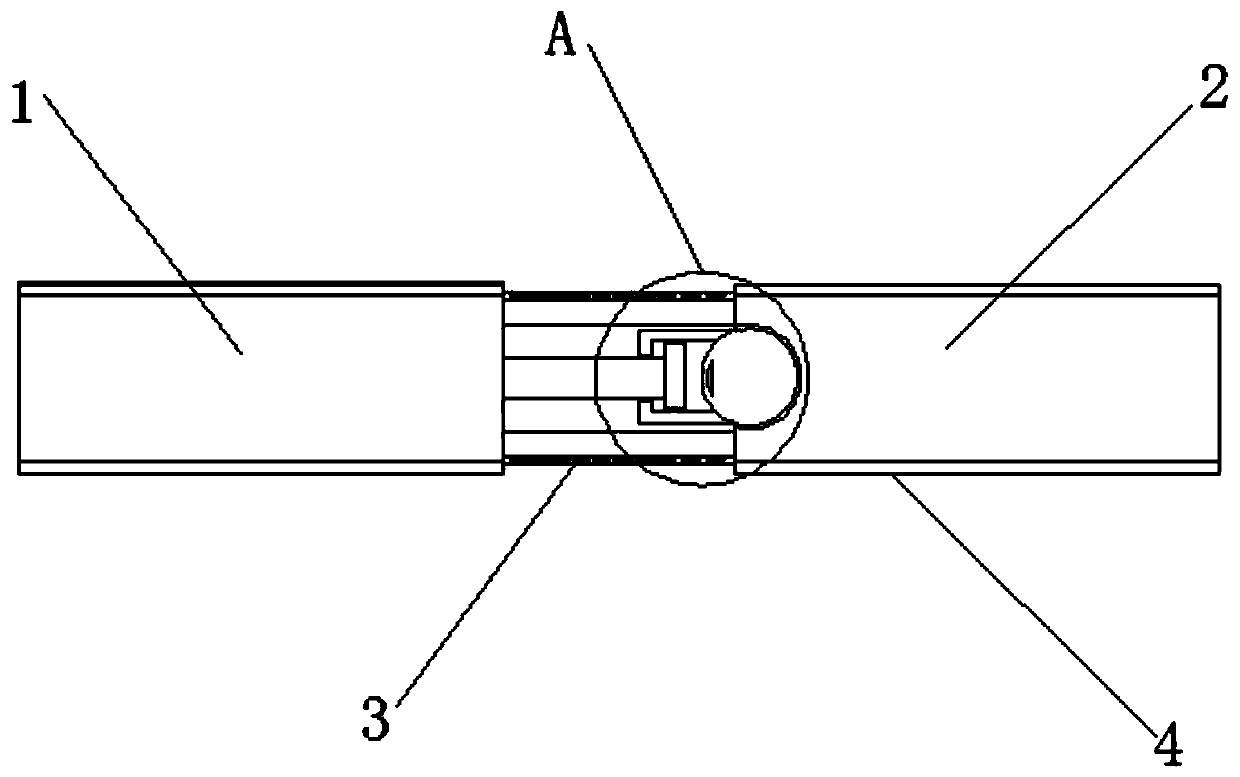

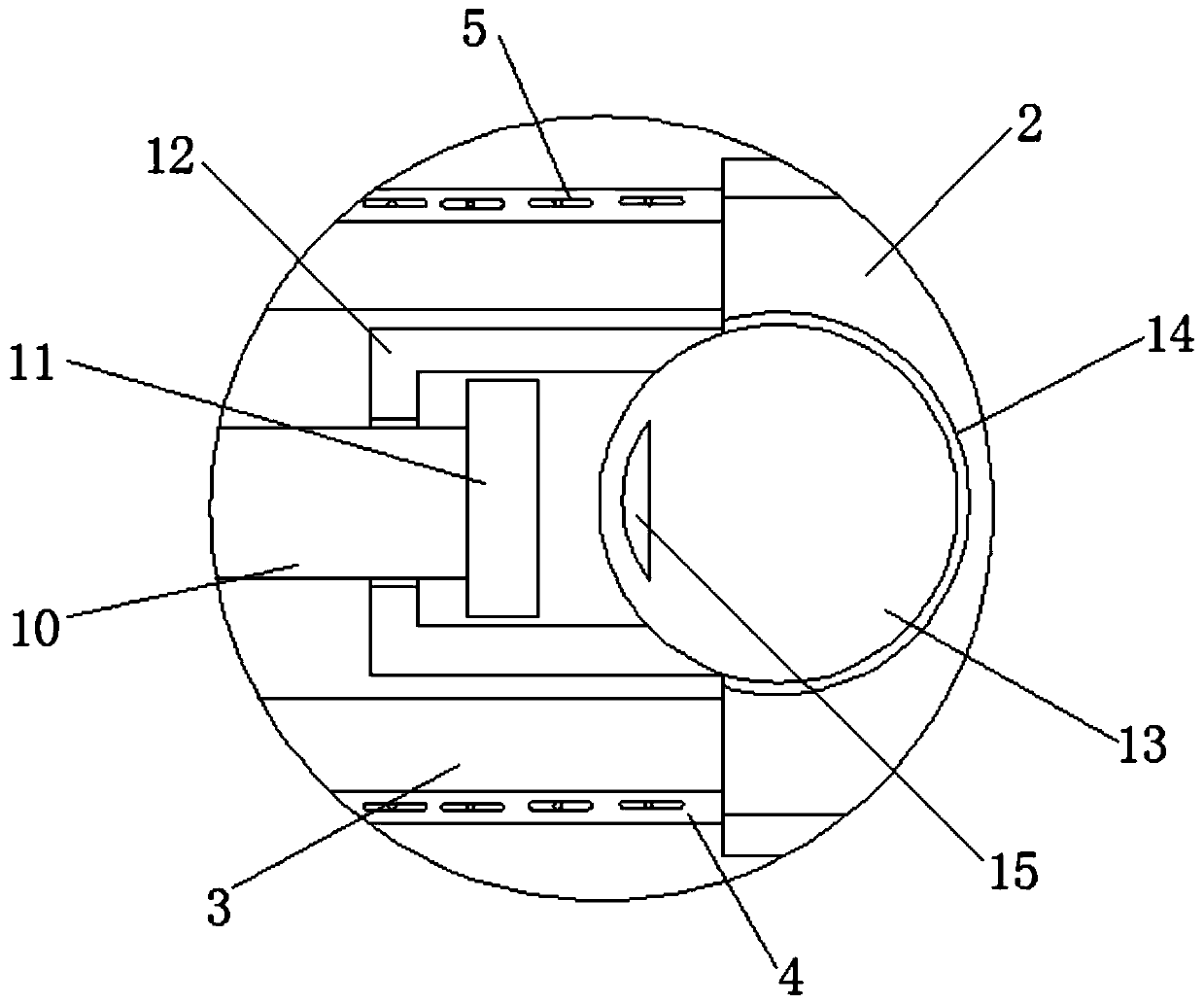

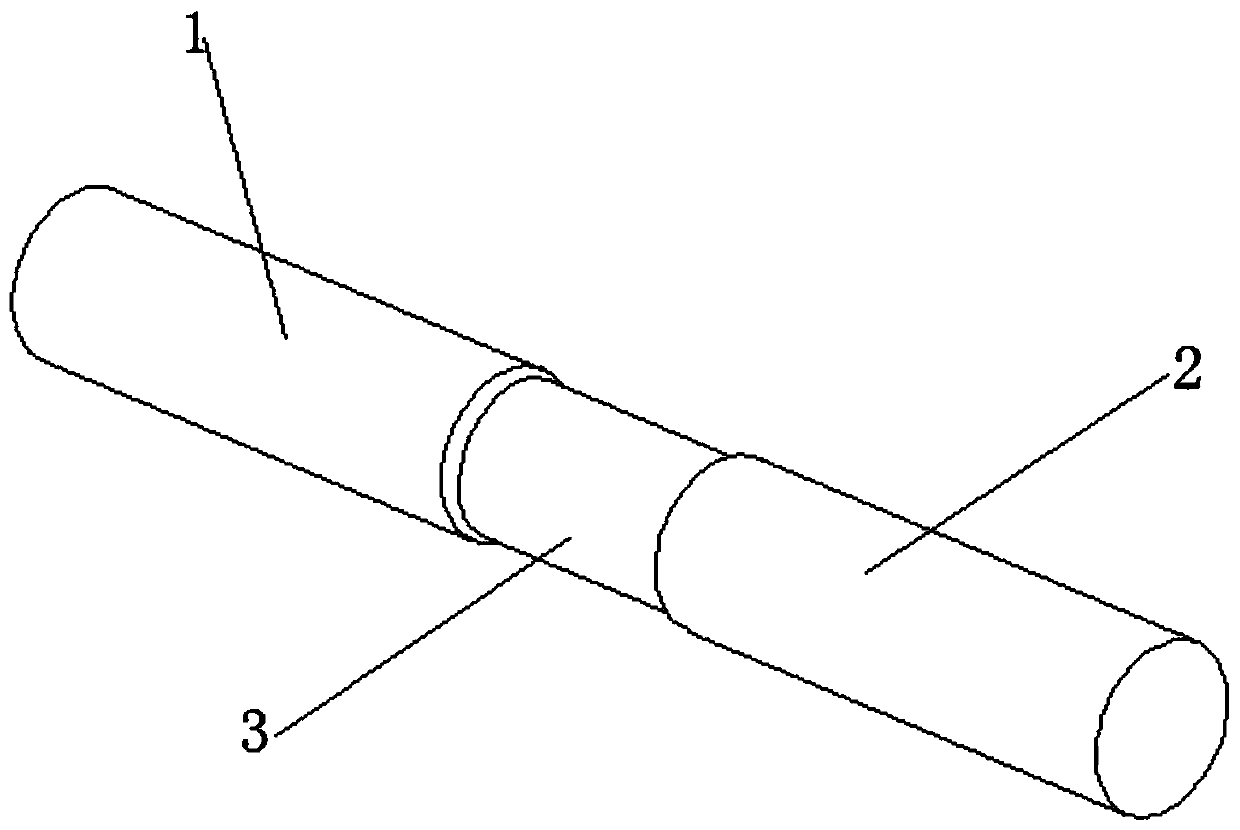

[0041] See Figure 1-8 , A steel structure connecting piece filled with pre-break warning bars, comprising a first steel piece 1 and a second steel piece 2 with a steel structure connecting piece 3 connected between the ends. The surface of the steel structure connecting piece 3 is coated with a coating 4, The surface of the first steel piece 1 and the second steel piece 2 are also coated with a coating 4, and the coating 4 on the surface of the steel structure connection piece 3 is mixed with a cross pre-break warning bar 5, and the steel structure connection piece 3 is tubular and has a steel structure The inner side of the connecting piece 3 is provided with a built-in protection mechanism, which includes a built-in connecting rod 10 and a built-in connection auxiliary device. One end of the embedded connecting rod 10 is connected to the first steel piece 1, and the other end of the embedded connecting rod 10 passes through The embedded connection auxiliary device is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com