Semi-sealed device of four-ram blowout preventer of coiled tubing and method

A technology of blowout preventer and four rams, which is applied in earthwork drilling, sealing/isolation, wellbore/well components, etc., can solve the problems of half-sealing device failure, poor sealing, failure, etc., and avoid half-sealing Ineffectiveness, avoiding man-made damage, reducing the effect of hard friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

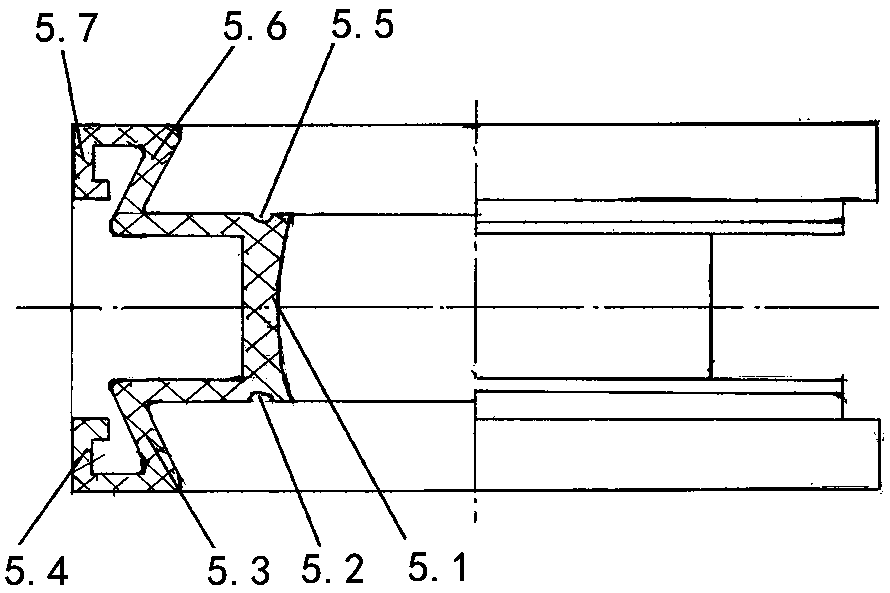

[0051] Example 2 is different from Example 1 in that the cross-section of the side of the setting expansion side (5.1) in contact with the coiled tubing of the present invention is an arc structure, and the cross-section of the other side is a protrusion that is conducive to rebound. arc structure.

[0052] The method of use is the same as in Example 1, the difference is that: as the hydraulic pressure increases, the expansion side of the setting (5.1) expands in one direction under the action of the pressure, forming a cup seal structure, so as to tightly and continuously. The outer wall of the tubing forms a seal; the cross section of the side in contact with the coiled tubing is an arc structure, forming a convex bowl bottom shape in the opposite direction.

Embodiment 3

[0053] Embodiment 3 is different from Embodiments 1 and 2: refer to the attached Figure 5 , the setting expansion side (5.1) of the present invention is a three-section structure, the section of the side in contact with the coiled tubing is composed of arc structure, plane structure and arc structure, and the middle section is plane structure. In this way, the middle plane structure is better combined with the outer wall of the coiled tubing, forming a larger sealing surface and a more durable sealing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com