Ventilation method for high gas extra-long tunnel construction

A technology for tunnel construction and ventilation methods, which is applied in mine/tunnel ventilation, earthwork drilling, mining equipment, etc., to reduce construction risks, improve ventilation effects, and ensure personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

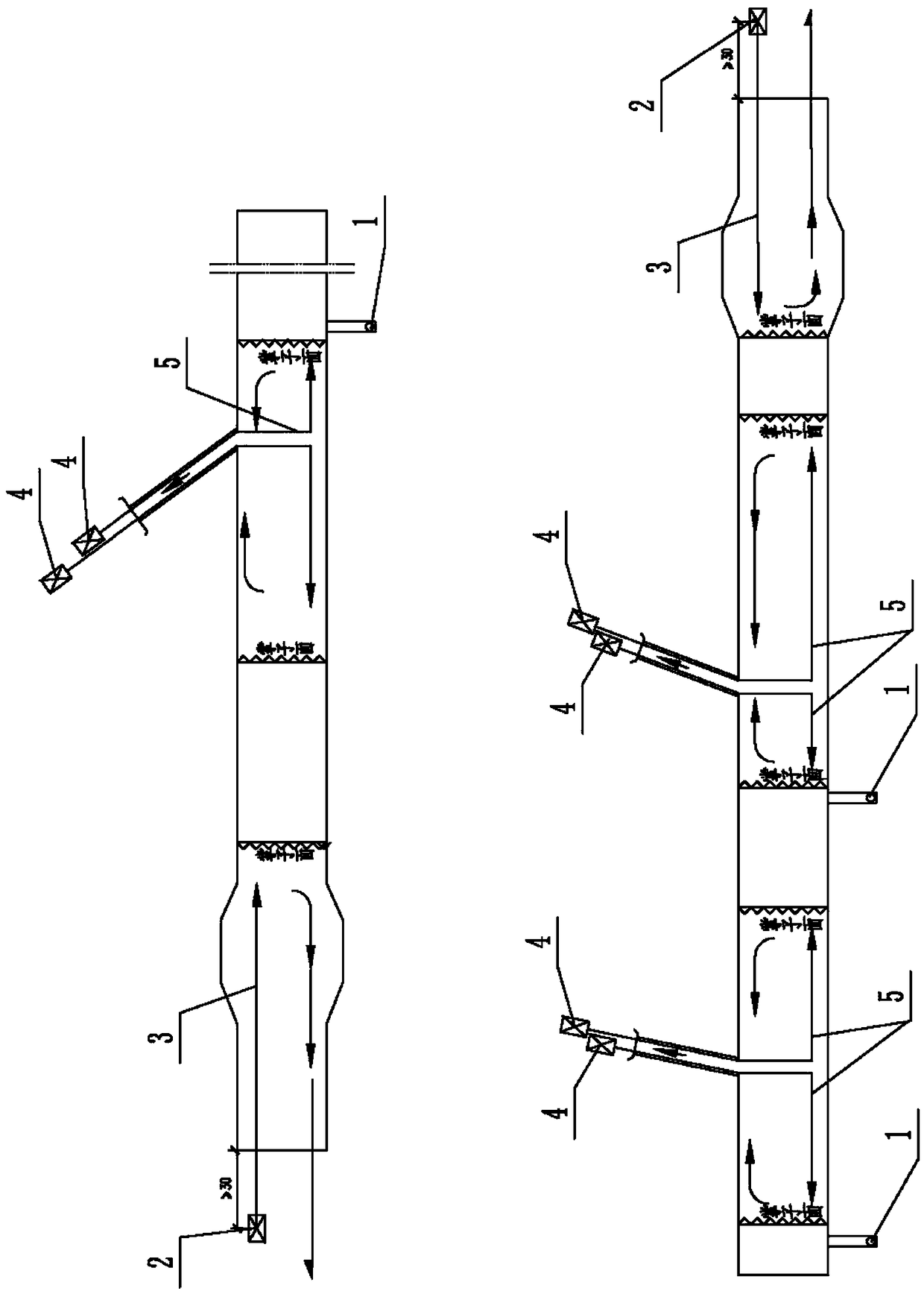

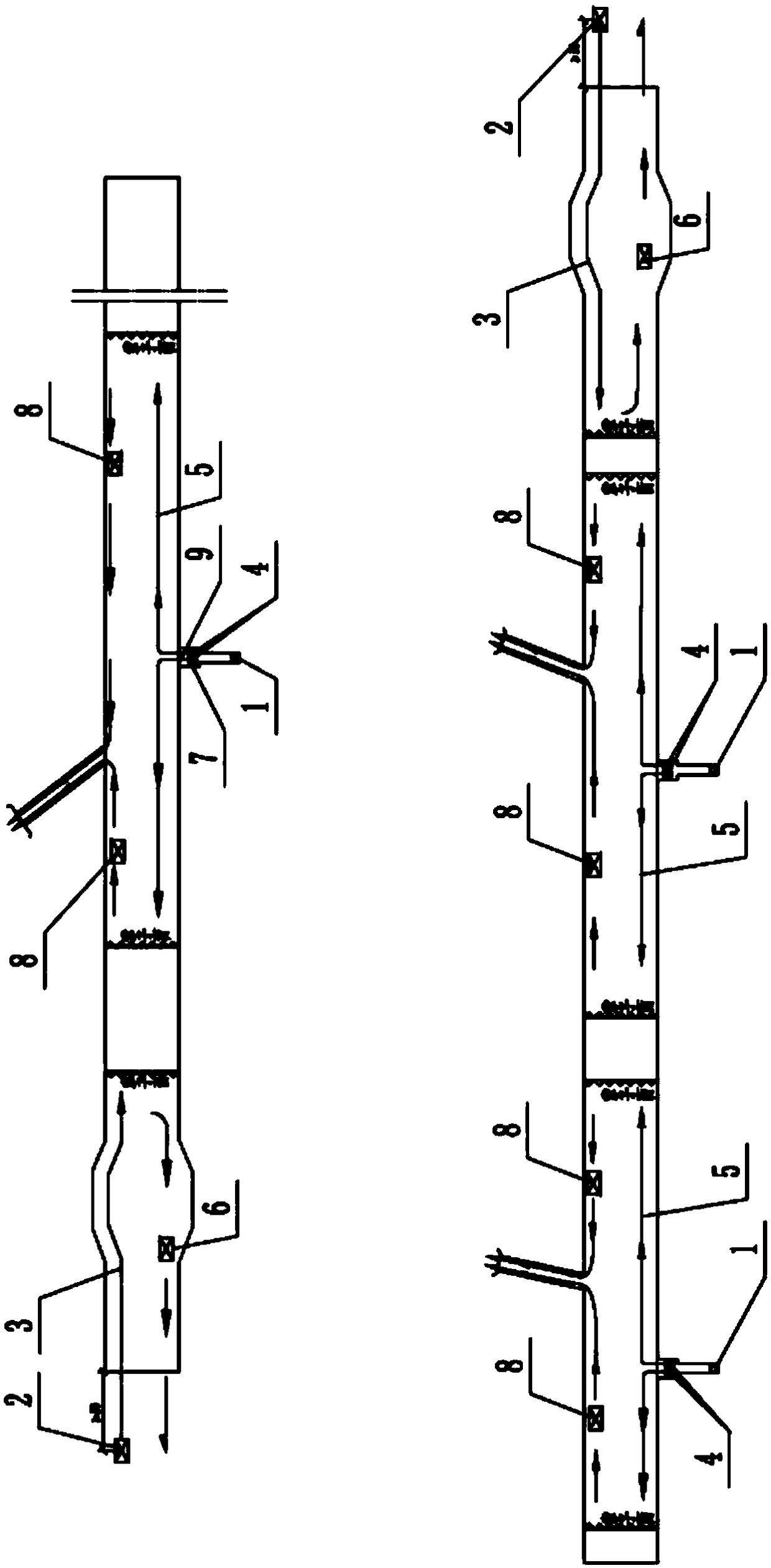

[0021] Attached below Figure 1-2 An embodiment of the present invention is described.

[0022] Step 1: Calculate the air volume required for tunnel construction ventilation according to the blasting smoke exhaust of the construction tunnel, the minimum allowable wind speed, the amount of gas gushing out, the maximum number of people working in the tunnel at the same time, and the use of internal combustion engine exhaust gas in the dilution tunnel, and select the maximum value ; Then according to the maximum air volume required for ventilation, select the models of the axial flow fan Ⅰ2, axial flow fan Ⅱ4, jet flow fan Ⅰ6, and jet flow fan Ⅱ8, and the axial flow fan Ⅱ4, jet flow fan Ⅰ6, and jet flow fan Ⅱ8 must be explosion-proof product. At the same time, a tile-electric locking system and a wind-powered locking system are installed in the tunnel and working conditions are set.

[0023] Step 2: Before the ventilation shaft 1 is penetrated, install an axial flow fan I2 at e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com