Fan filter unit detection robot system and detection method thereof

A robot system and fan filtering technology, which is applied in the testing of machine/structural components, testing of mechanical components, instruments, etc., can solve the problems of low detection accuracy, large influence of human error, long operation time, etc., to save manpower. Work intensity, precise positioning of the detection position, and the effect of fully automated detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

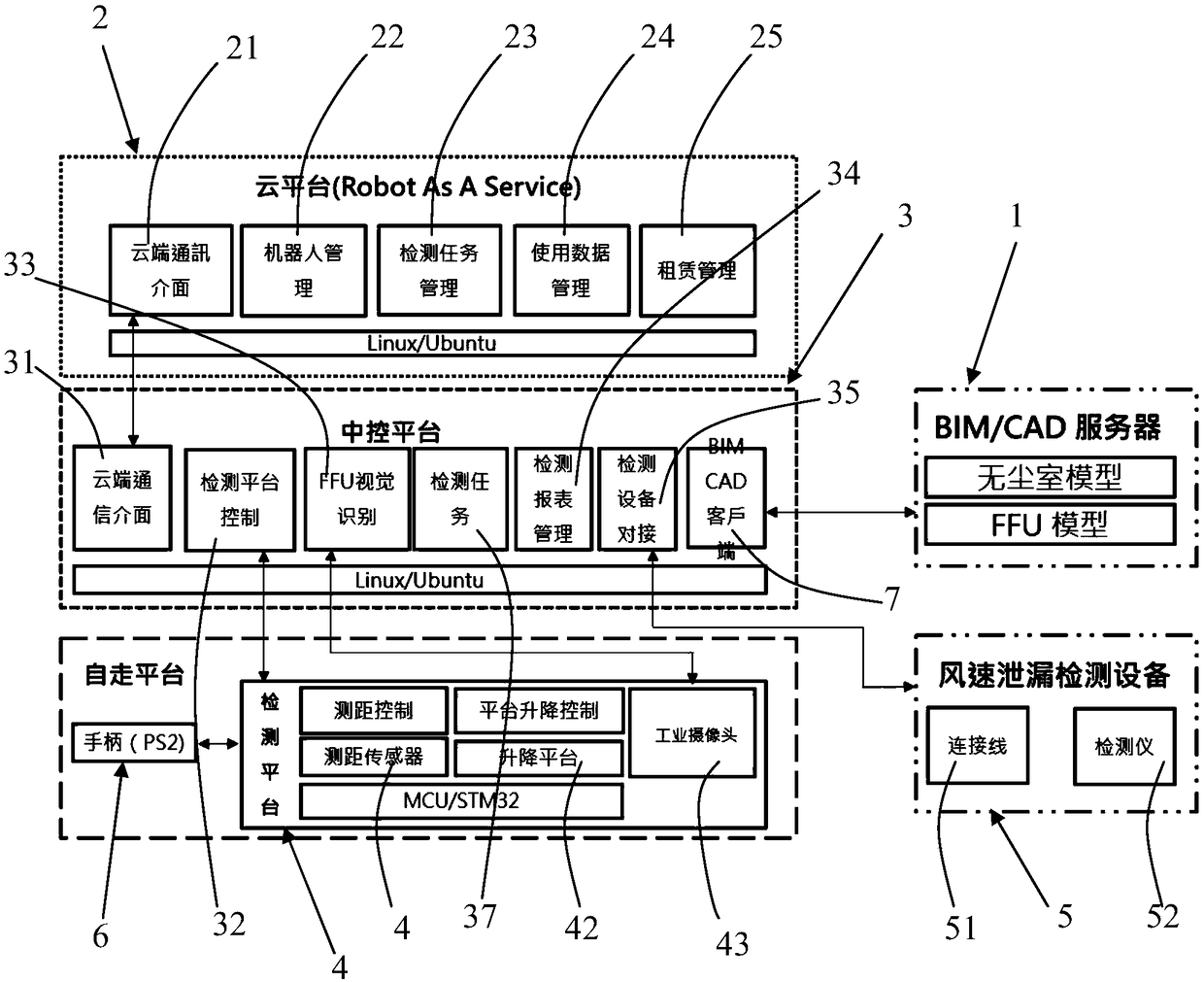

[0023] Such as figure 1 As shown, a fan filter detection robot system includes: Building Information Modeling (Building Information Modeling, BIM) server 1, cloud platform 2, building information modeling client 7, central control platform 3, detection platform 4, wind speed leakage detection A device (Fan Filter Unit, FFU) 5 and a handle 6 .

[0024] The BIM server 1 has a database of clean room models and fan filter unit models, and the BIM client 7 reads the clean room model and fan filter unit model data from the BIM server 1 and uploads them to the cloud platform 2 . The cloud platform 2 has a cloud communication interface 21 , a robot management module 22 , a detection task management module 23 , a usage data management module 24 and a leasing module 25 .

[0025] The central control platform 3 includes a cloud communication interface 31 , a detection platform control module 32 , a visual recognition module 33 , a detection report management module 34 , and a detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com