Breaking stress testing device for polyimide moulding pipe and application thereof

A destructive stress and polyimide technology, applied in the direction of measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve the effect of gravity, affect test results, unbalanced pressure of power mechanism and connecting rod, etc. problem, to achieve the effect of reducing impact, reducing friction, and avoiding the effect of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

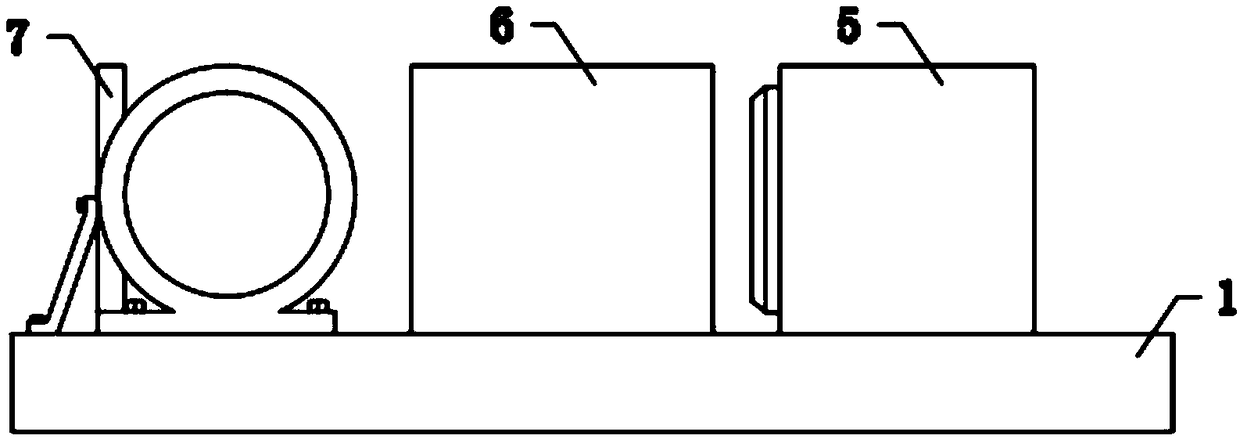

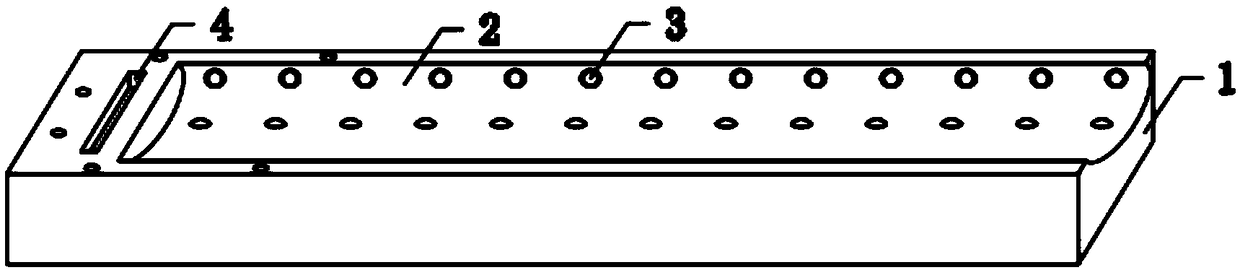

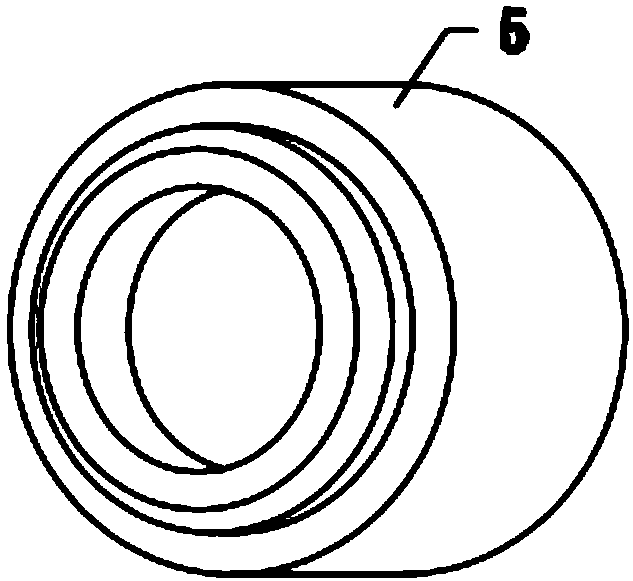

[0023] see Figure 1-4 , the present invention provides a technical solution: a polyimide molded part pipe body failure stress test device, including a support table 1, a pressure column 6 and a baffle mechanism 7, the middle of the upper surface of the support table 1 is horizontally opened with a receiving groove 2 , the inner wall of the accommodating groove 2 is evenly embedded with anti-friction balls 3, the left side of the upper surface of the support table 1 is longitudinally provided with a mounting slot 4, the baffle mechanism 7 is fixedly installed on the top left end of the support table 1 by screws, and the baffle plate The mechanism 7 includes a rear supporting half ring 71, a front supporting ring 72, and a top plate 73 arranged between the rear supporting half ring 71 and the front supporting ring 72. The lower end of the top plate 73 is embedded in the mounting slot 4, and the rear supporting half rings 71, The bottom ends of the front support ring 72 are resp...

Embodiment 2

[0025] like Figure 1-4 As shown in the figure, the failure stress test device for the pipe body of the polyimide molded part includes a support table 1, a pressure column 6 and a baffle mechanism 7. The middle part of the upper surface of the support table 1 is provided with a receiving groove 2 horizontally, and the inner wall of the receiving groove 2 The anti-friction balls 3 are evenly embedded on the upper surface of the support table 1, and a mounting slot 4 is longitudinally opened on the left side of the upper surface of the support table 1. The baffle mechanism 7 is fixedly installed on the top left end of the support table 1 by screws. The baffle mechanism 7 includes a rear support half. The ring 71, the front support ring 72 and the top plate 73 arranged between the rear support half ring 71 and the front support ring 72, the lower end of the top plate 73 is embedded in the installation slot 4, the rear support half ring 71, the bottom of the front support ring 72 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com