Distillation flask and system and method for ignition-free closed flash point determination of petroleum products

A petroleum product and closed flash point technology, applied in the field of petroleum refining, can solve the problems of low experimental precision, high risk, large test error, etc., and achieve the effects of improving measurement efficiency, high experimental precision and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

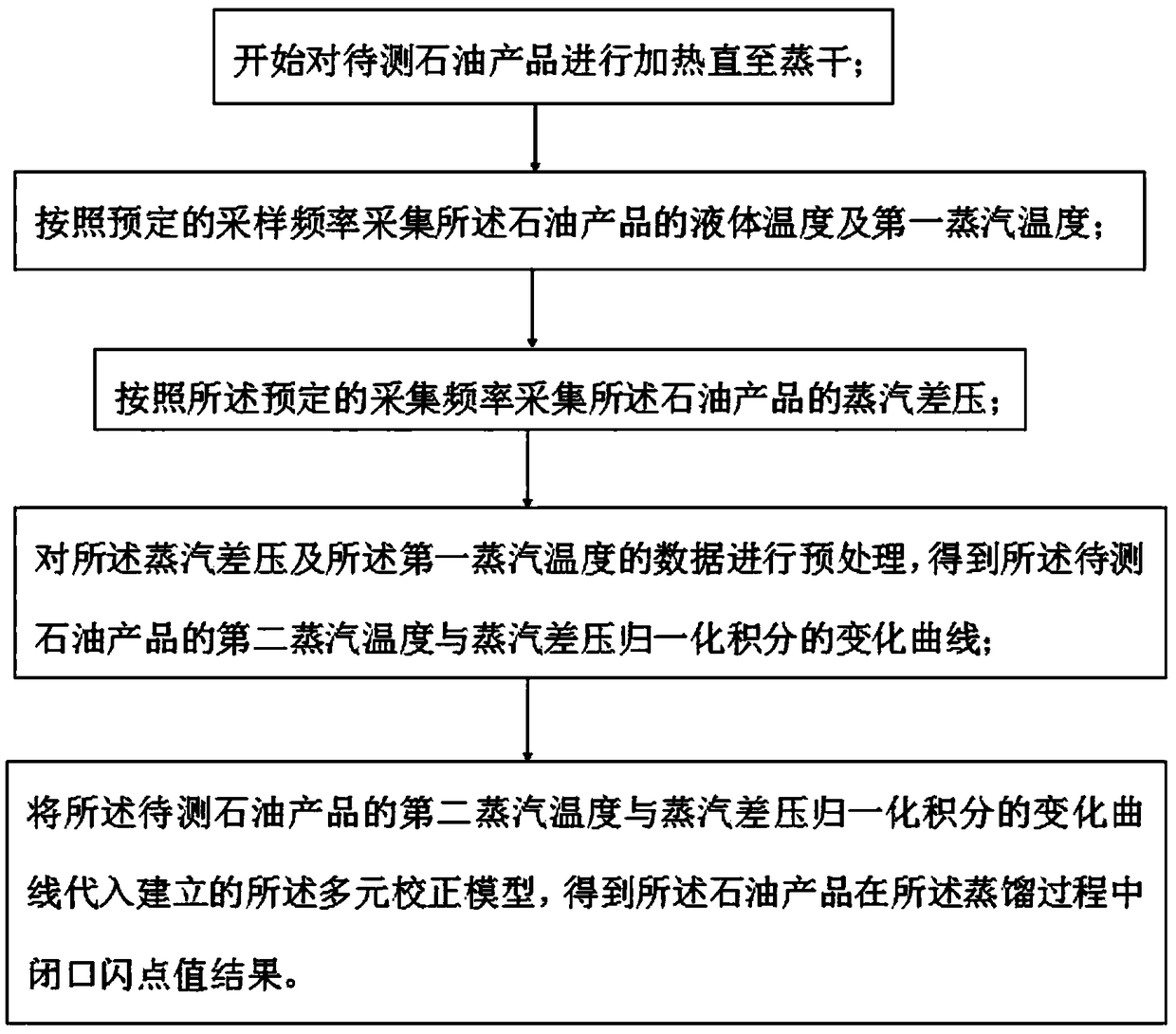

[0049] Such as figure 1 As shown, the embodiment of the present invention discloses a method for determining the non-ignition closed flash point of petroleum products, and the steps include:

[0050] 1) Start to heat the petroleum product to be tested until it evaporates to dryness;

[0051] 2) collecting the liquid temperature and the first steam temperature of the petroleum product according to a predetermined sampling frequency;

[0052] 3) collecting the steam differential pressure of the petroleum product according to the predetermined collection frequency;

[0053] 4) Preprocessing the data of the steam differential pressure and the first steam temperature to obtain a change curve of the normalized integral of the second steam temperature and steam differential pressure of the petroleum product to be tested;

[0054] 5) Substituting the change curve o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com