Thermal Error Prediction Method of Machine Tool Spindle Based on Genetic Algorithm and Wavelet Neural Network

A technology of wavelet neural network and machine tool spindle, which is applied in the thermal error prediction of machine tool spindle, and in the field of thermal error prediction of machine tool spindle based on genetic algorithm wavelet neural network, which can solve the unsatisfactory effect of thermal error compensation of machine tools and the difficulty of accurately establishing thermal error compensation Model and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below through the embodiments in conjunction with the accompanying drawings.

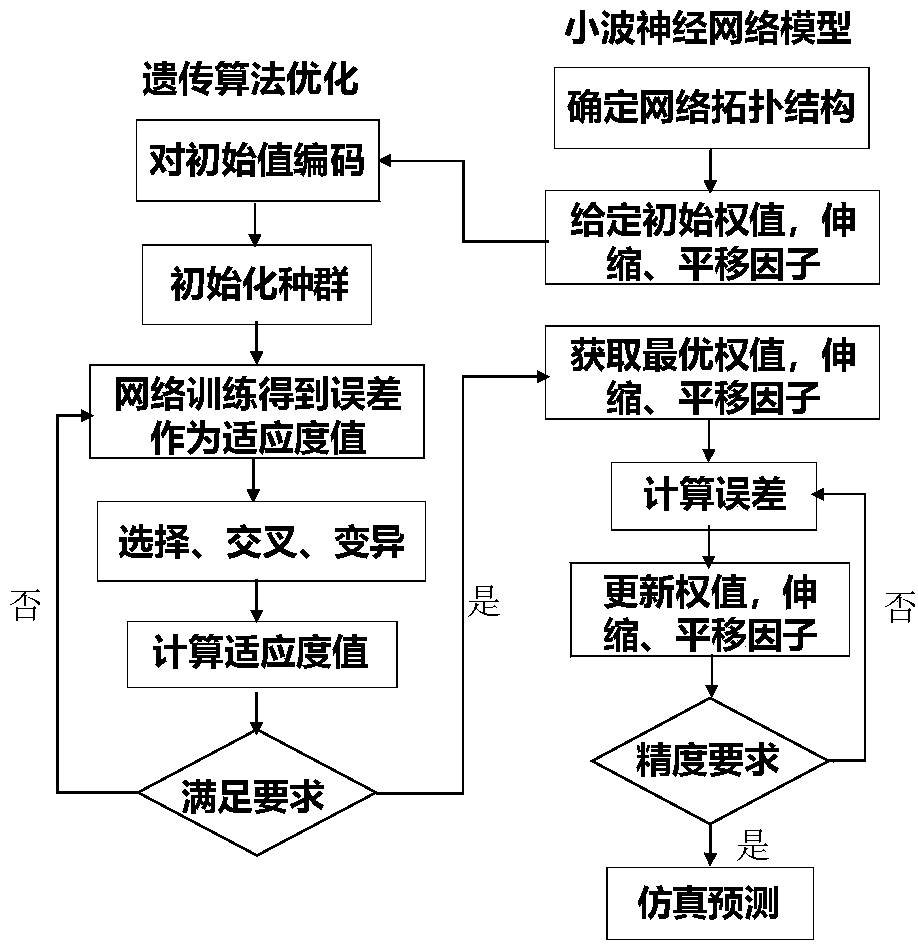

[0064] see figure 1 , a method for predicting the thermal error of a machine tool spindle based on a genetic algorithm wavelet neural network, which specifically includes the following steps:

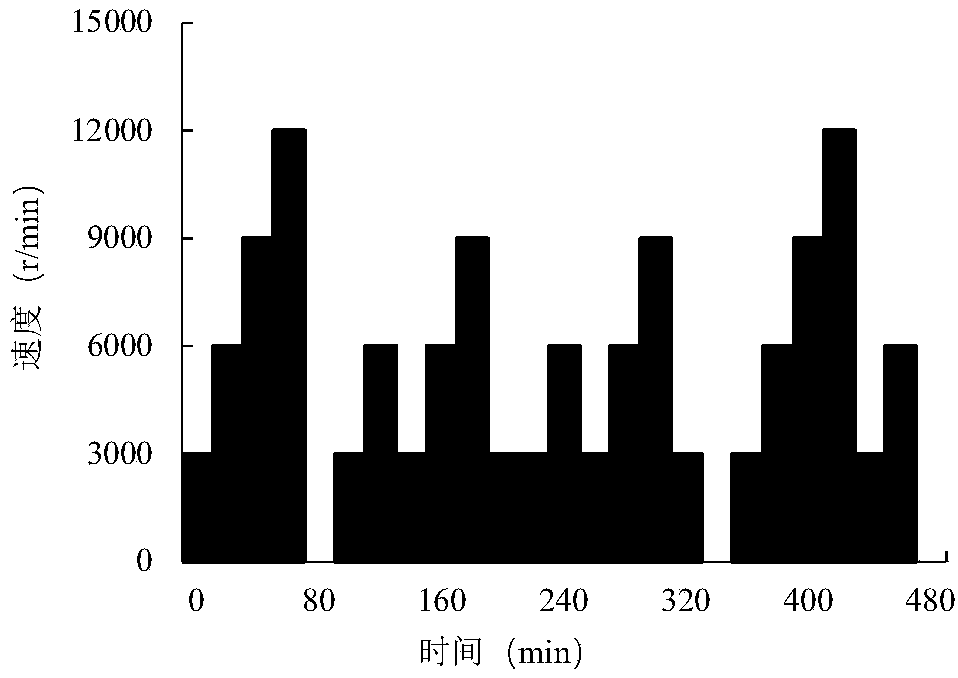

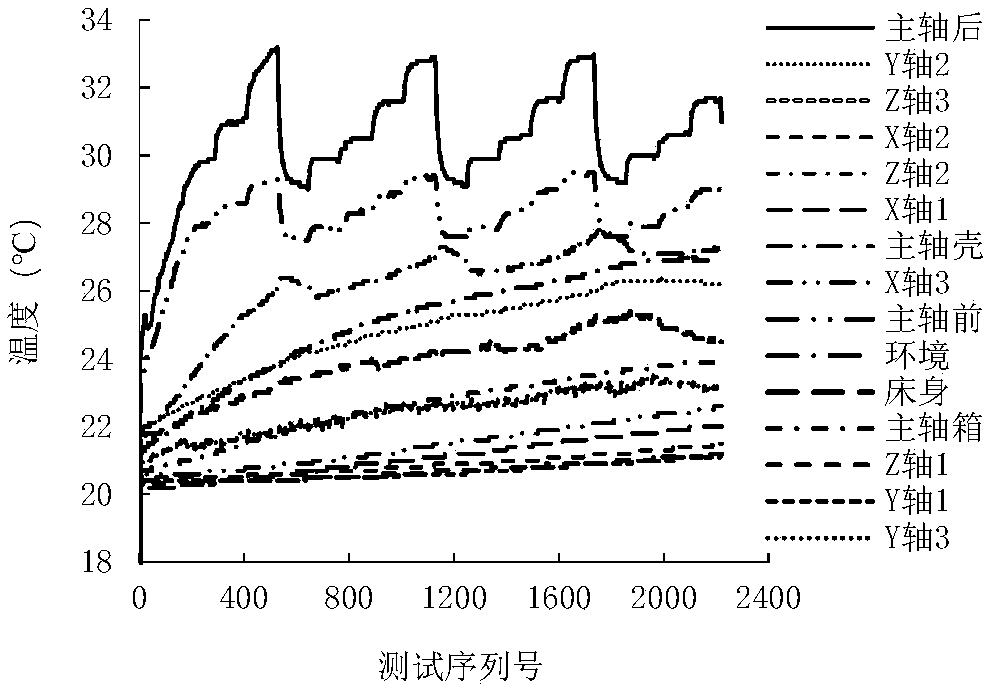

[0065] 1) The spindle of the machine tool runs at the set spindle speed, and the temperature sensor is used to measure the temperature of the key temperature measuring point of the machine tool and the temperature data of the processing environment, and the displacement sensor is used to obtain the thermal error data of the spindle of the machine tool; the temperature sensor can use a contact resistance temperature sensor, The displacement sensor should adopt a non-contact laser displacement sensor.

[0066] Taking a certain type of five-axis swing horizontal machining center as an example, its basic structure and factors that may cause thermal errors ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com