A method for regenerating vanadium electrolyte from the cathode electrolyte of a failed vanadium battery

A positive electrolyte and electrolyte technology, applied in the field of vanadium batteries, can solve the problems of low utilization rate, cumbersome recycling process of invalid vanadium electrolyte, etc., and achieve the effects of easy operation, avoiding waste, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

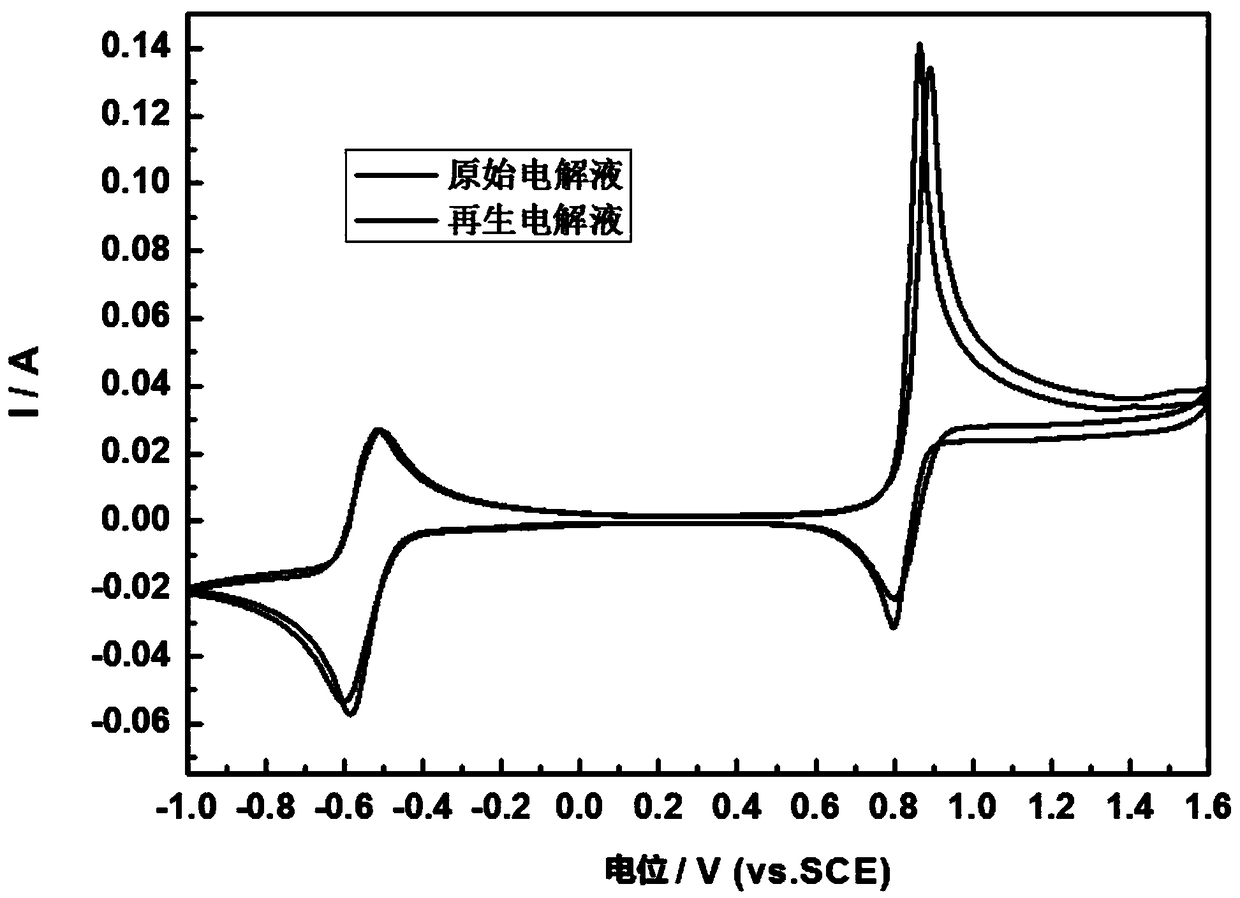

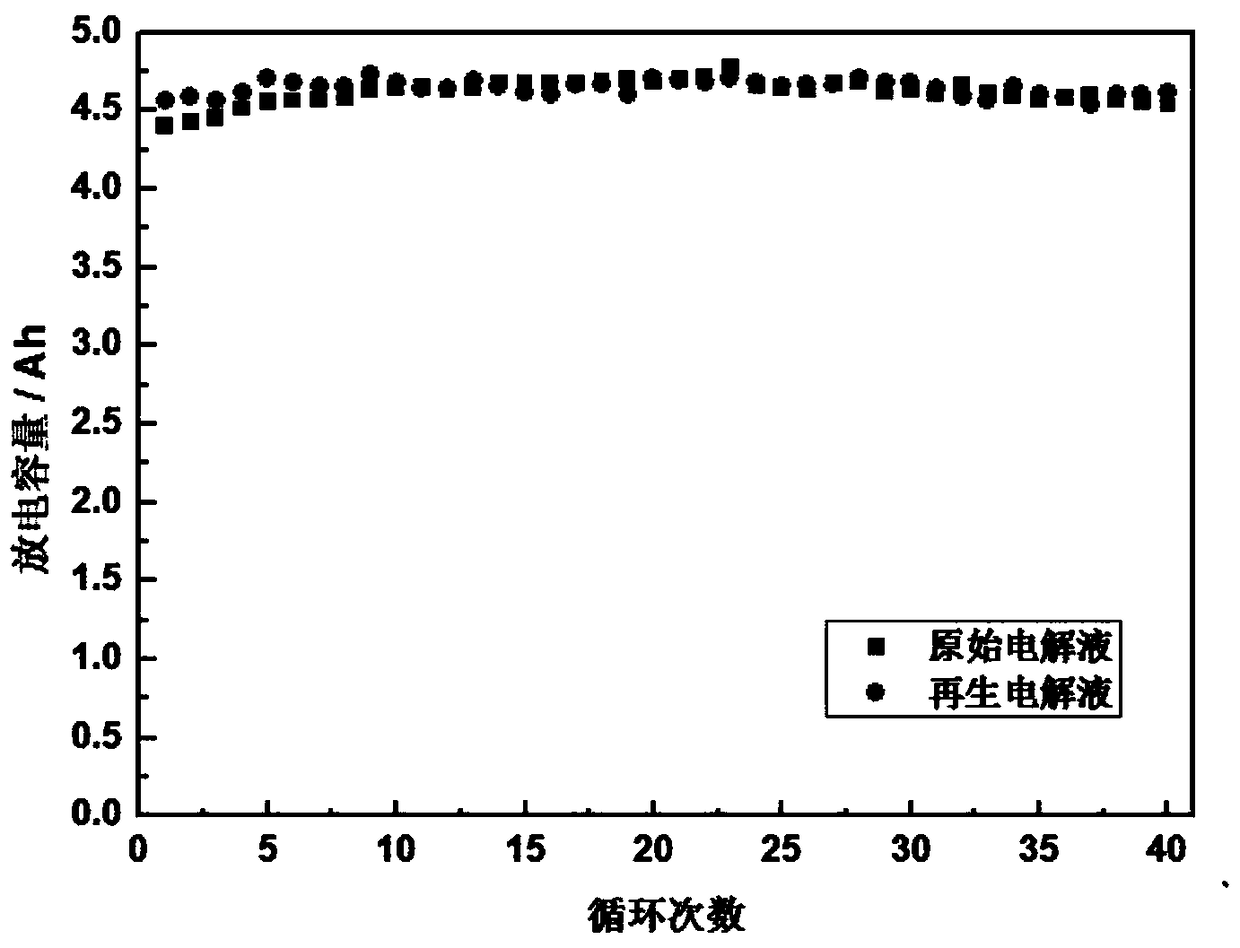

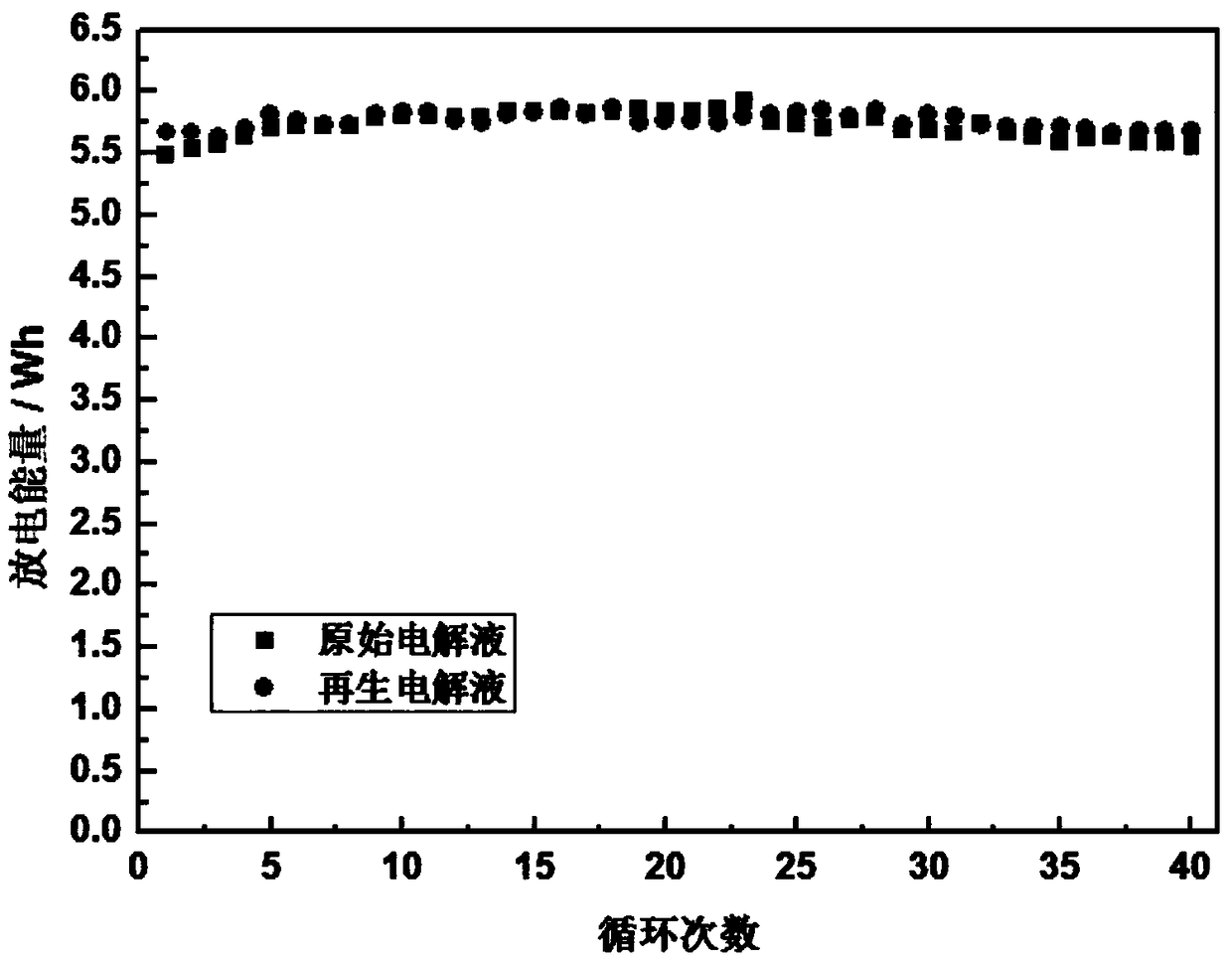

[0037] Embodiment 1 adopts the inventive method to prepare vanadium battery electrolyte

[0038] Using the chemical titration method, the concentration of vanadium ions in the vanadium electrolyte of the invalid positive electrode was measured to be 1.5mol / L, and the average valence state was +4.6; the concentration of chloride ions in the vanadium electrolyte of the invalid positive electrode was measured to be 5.6mol / L; The volume is 20.0L. The vanadium ion concentration of the regenerated electrolyte is 1.6mol / L, and the chloride ion concentration is 6.4mol / L. Therefore, calculate according to formula (1) the amount of substance n1 of required divalent solid vanadium dichloride to be 22.0mol, calculate the volume V2 of regenerated electrolyte according to formula (2) be 32.5L, calculate according to formula (3) The amount of material to give the desired HCl was 52.0 mol. Finally, according to the calculation results, add 22.0 mol of divalent vanadium dichloride and 52.0 m...

Embodiment 2

[0041] Embodiment 2 adopts the inventive method to prepare vanadium battery electrolyte

[0042] Using chemical titration, the concentration of vanadium ions in the invalid positive vanadium electrolyte was 1.7mol / L, and the average valence state was +4.5; the chlorine ion concentration in the invalid vanadium electrolyte was 6.1mol / L; The volume is 30.0L. The vanadium ion concentration of the regenerated electrolyte is 1.7mol / L, and the chloride ion concentration is 6.4mol / L. Therefore, calculate according to formula (1) the amount of substance n1 of required divalent solid vanadium dichloride to be 34.0mol, calculate the volume V2 of regenerated electrolyte according to formula (2) be 50.0L, calculate according to formula (3) The amount of material to give the desired HCl was 69.0 mol. Finally, according to the calculation results, add 34.0mol of divalent solid vanadium dichloride and 69.0mol of HCl to the 30.0L spent vanadium electrolyte, and then adjust the volume of the...

Embodiment 3

[0043] Embodiment 3 adopts the inventive method to prepare vanadium battery electrolyte

[0044]Using chemical titration, the concentration of vanadium ions in the invalid positive vanadium electrolyte was 1.4mol / L, and the average valence state was +4.1; the chlorine ion concentration in the invalid vanadium electrolyte was 5.8mol / L; The volume is 50.0L. The vanadium ion concentration of the regenerated electrolyte is 1.6mol / L, and the chloride ion concentration is 6.4mol / L. Therefore, calculate according to formula (1) the amount of substance n1 of required divalent solid vanadium dichloride to be 28.0mol, calculate the volume V2 of regenerated electrolyte according to formula (2) be 61.25L, calculate according to formula (3) The amount of material to give the desired HCl was 41.5 mol. Finally, according to the calculation results, add 28.0 mol of divalent solid vanadium dichloride and 46.0 mol of HCl to 50.0 L of spent vanadium electrolyte, and then adjust the volume of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com