An air-bearing rotor bearingless motor with slot wedge ventilation

A bearingless motor and rotor technology, used in electrical components, electromechanical devices, electric components, etc., can solve the problems of increasing the size and complexity of the motor stator, reducing the motor efficiency and power density, and excessively long axial length. Achieve the effect of eliminating mechanical bearings, suppressing rotor temperature rise, and shortening length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

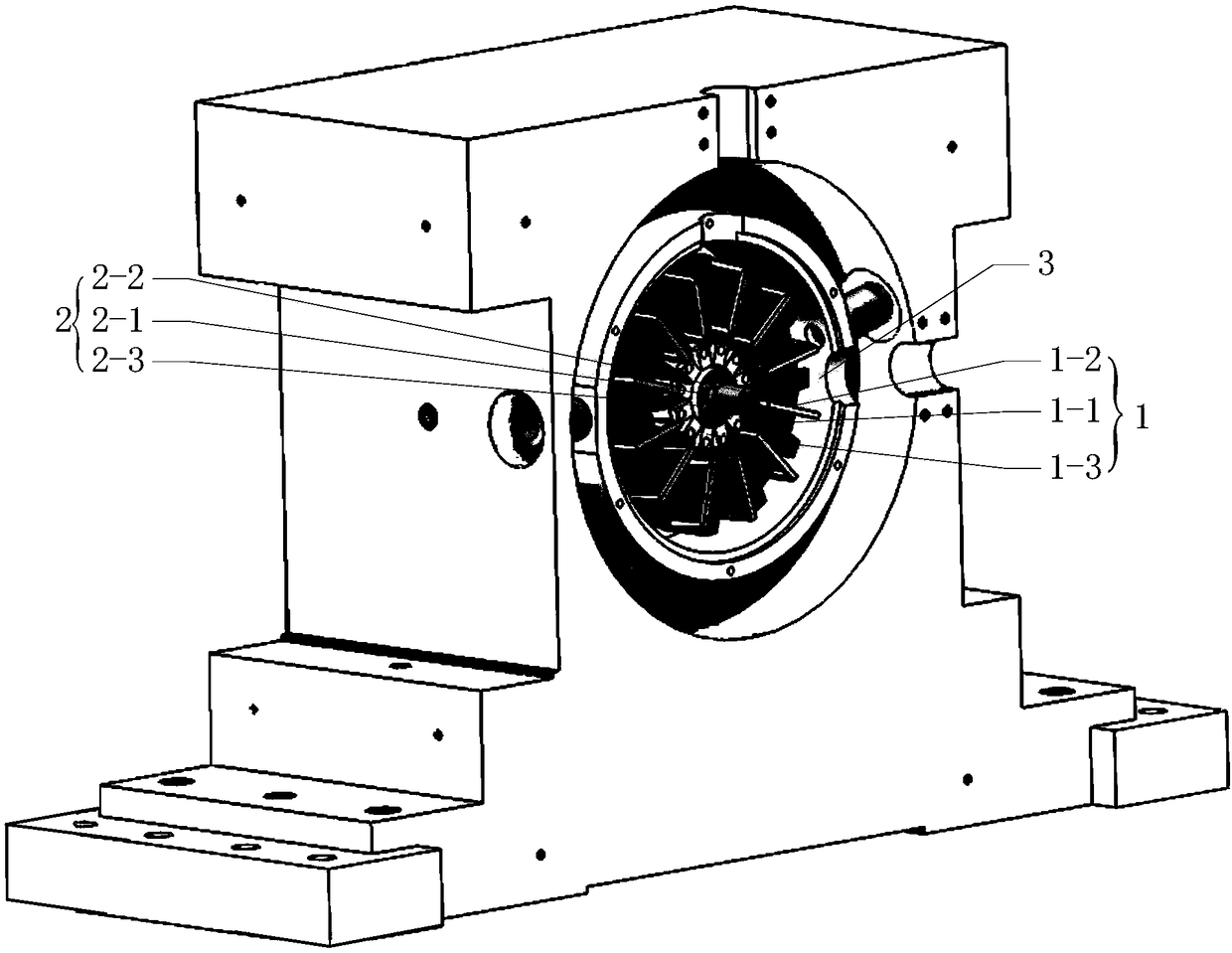

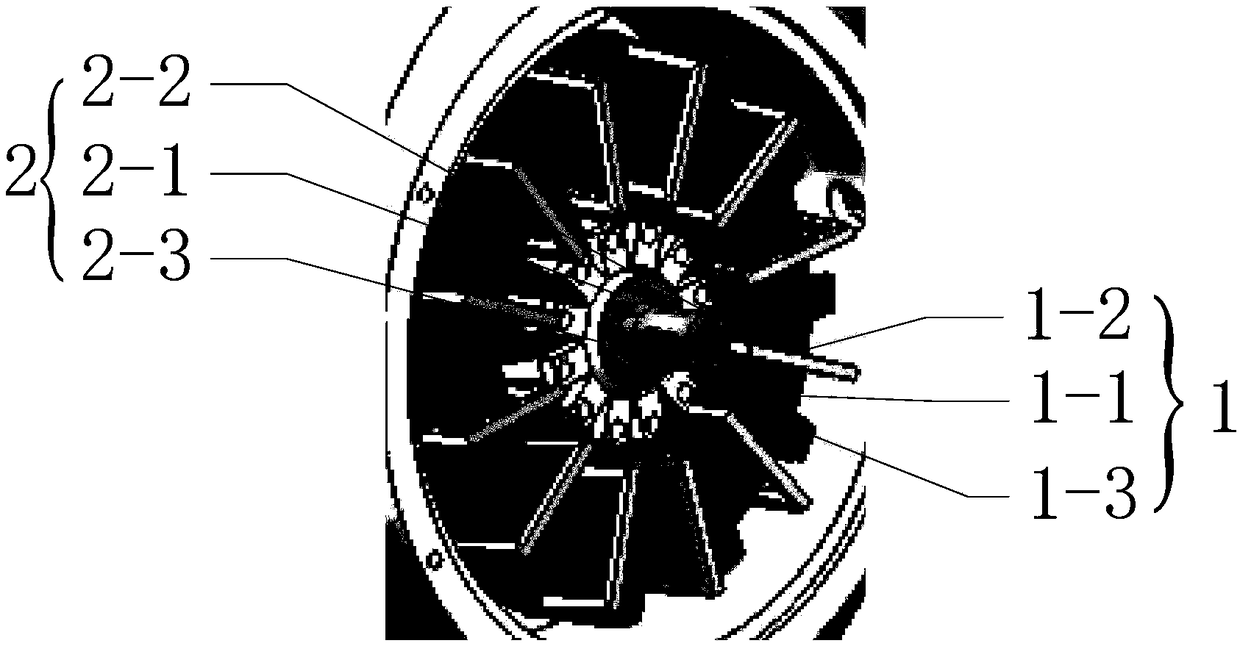

[0031] Specific implementation mode 1: Combination Figure 1 to Figure 3 Detailed description of this embodiment, a slot-wedge ventilated air-floating rotor bearingless motor described in this embodiment includes a stator 1, a rotor 2 and a casing 3;

[0032] The stator 1 is fixed in the casing 3, the rotor 2 is sleeved in the stator 1, and there is an air gap between the stator 1 and the rotor 2;

[0033] The stator 1 includes a stator core 1-1, a stator winding 1-2 and a slot wedge 1-3;

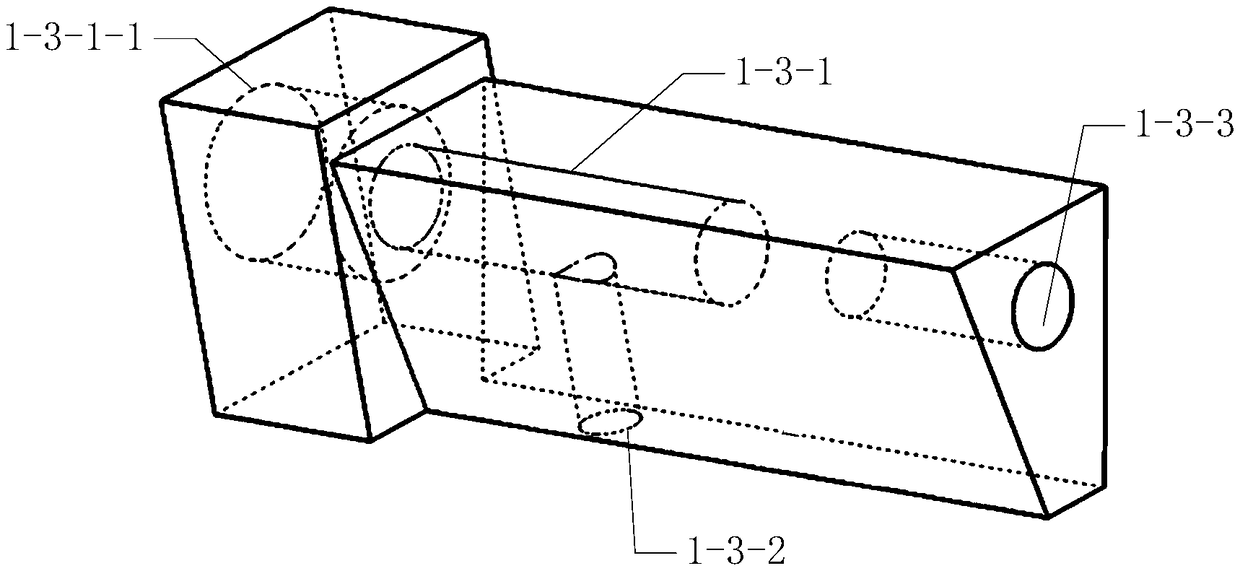

[0034] The stator core 1-1 is fixed to the casing 3. The stator core 1-1 has multiple slots evenly along the circumferential direction, each slot is provided with a stator winding 1-2, and each inner slot is fixed with a slot wedge 1 -3, the slot wedge 1-3 is provided with an air supply channel 1-3-1 and a throttle hole 1-3-2, and the throttle hole 1-3-2 communicates with the air supply channel 1-3-1 and faces the rotor 2. ;

[0035] The gas is input into the gas supply channel 1-3-1 and ejected ...

specific Embodiment approach 2

[0045] Specific embodiment 2: This embodiment is a further description of a slot wedge ventilated air-floating rotor bearingless motor described in the first embodiment. In this embodiment, the slots opened by the stator core 1-1 are open slots .

[0046] In order to ensure sufficient air supply, the diameter of the orifice 1-3-2 in the slot wedge 1-3 should be increased to produce greater suspension force. For this reason, the stator slot should be an open slot, and the slot wedge 1-3 Use magnetic slot wedges to reduce the distortion rate of the air gap magnetic field.

specific Embodiment approach 3

[0047] Specific embodiment three: This embodiment is a further description of a slot-wedge ventilated air-floating rotor bearingless motor described in specific embodiment 1. In this embodiment, the magnetizing direction of the rotor poles 2-1 is radial , In order to reduce the harmonic components of the air gap magnetic field.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com