Clutch housing and clutch

A clutch housing and clutch technology, applied in clutches, friction clutches, mechanical drive clutches, etc., can solve the problems of lowering the temperature of the clutch housing, affecting the performance of the clutch, shortening the service life, etc., to prevent the entry of external impurities, and to achieve good ventilation and heat dissipation. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

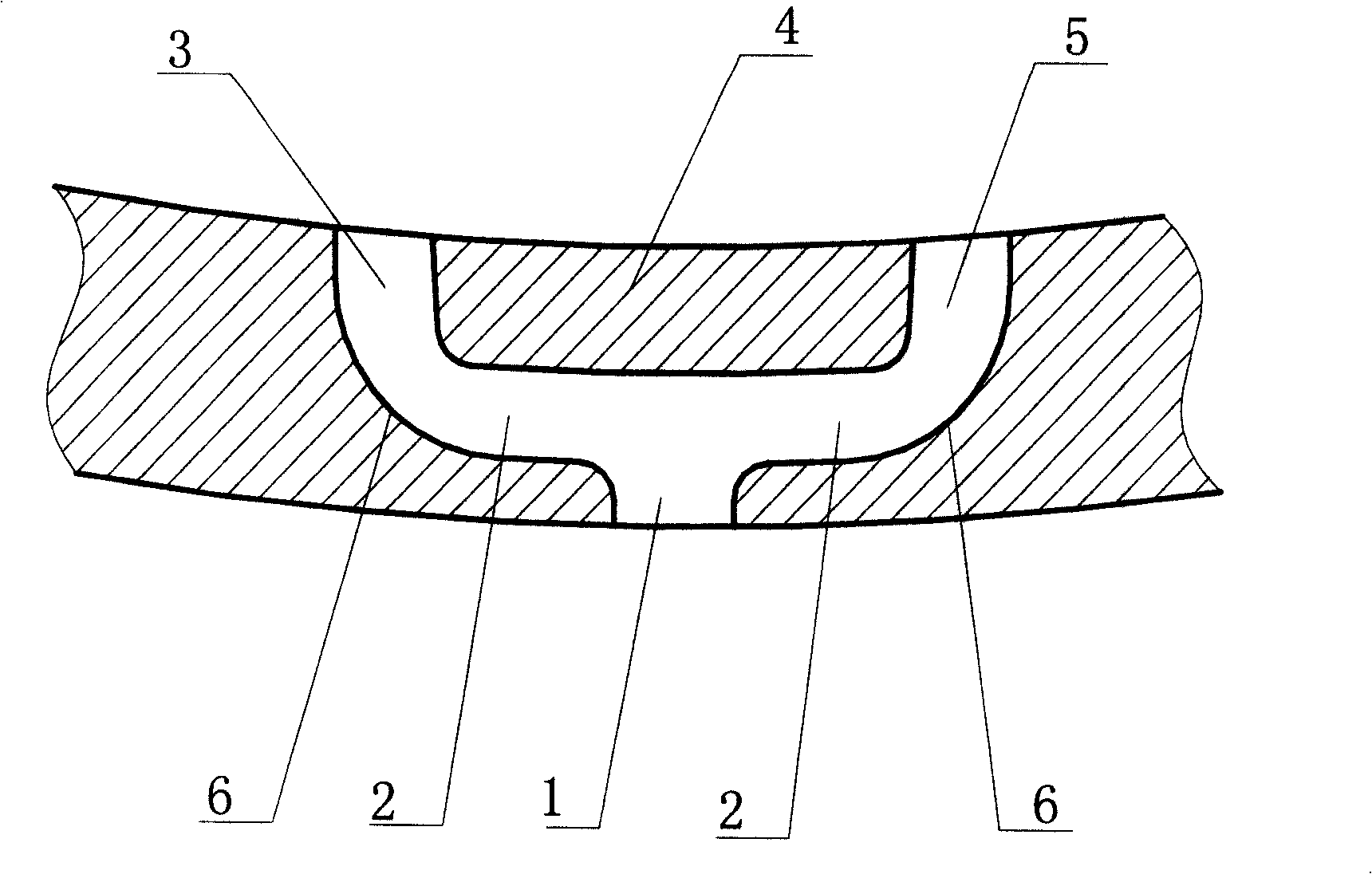

[0022] like figure 1 As shown in the figure, the cross-sectional shape of the hole in this example is approximately "Y" shape. When viewed from the outside of the clutch housing, the hole is located on the outer wall of the clutch housing with only one opening. When viewed from the inside of the clutch housing, the hole is located on the inner wall of the clutch housing. There are two openings. Open your mouth. The shorter outer channel 1 is opened on the outer wall of the clutch housing, which is opposite to the dust-blocking wall 4, and communicates with the middle channel 2 and is almost vertical. The left inner hole 3 and the right inner hole 5 are opened on the inner wall of the clutch housing.

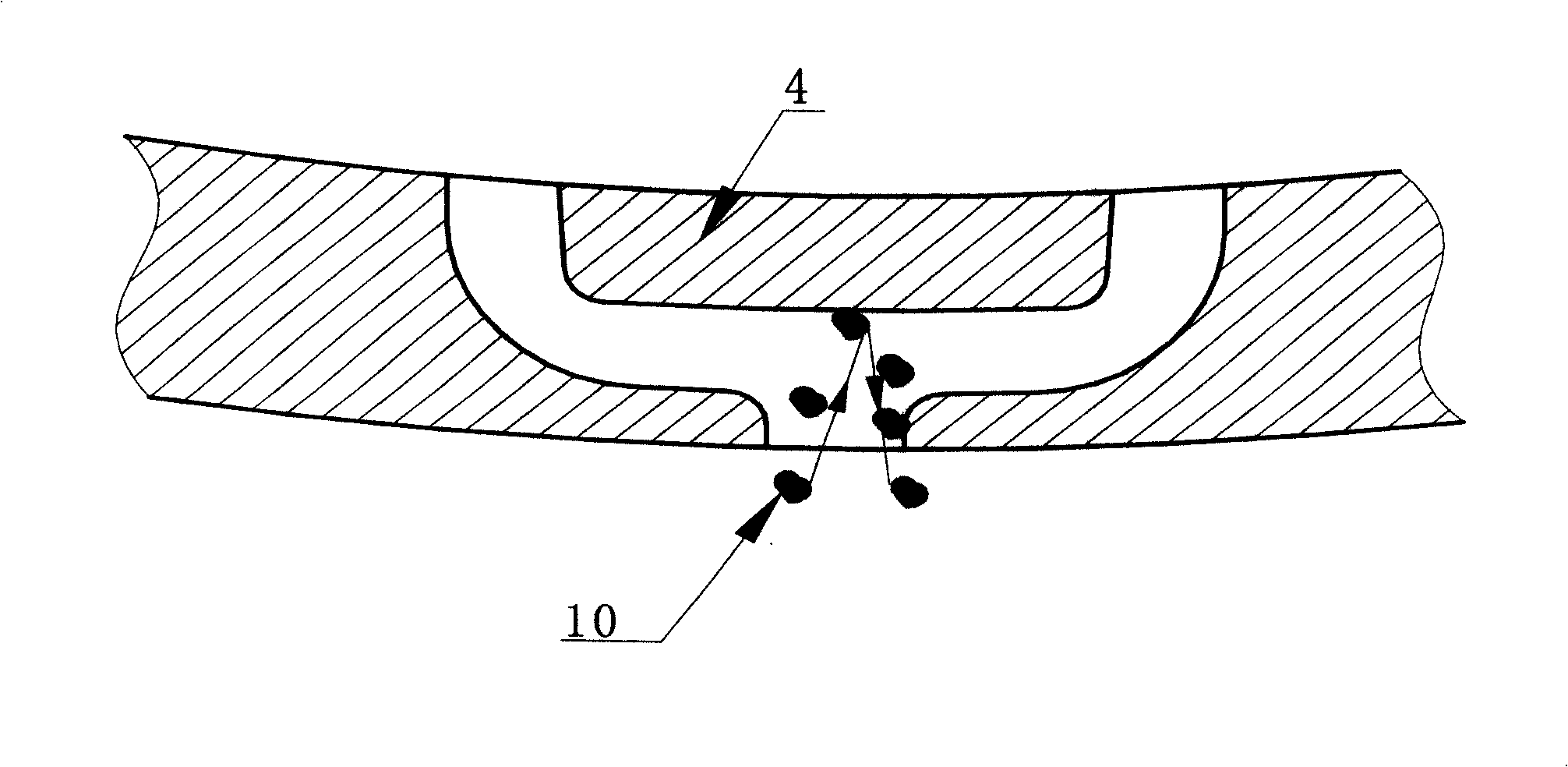

[0023] like figure 2 As shown, on the outer wall of the clutch housing, the approximately "Y"-shaped channel has only one opening, and the area communicating with the outside is small, which reduces the chance of external impurities 10 entering the outer channel 1 .

[0024] ...

Embodiment 2

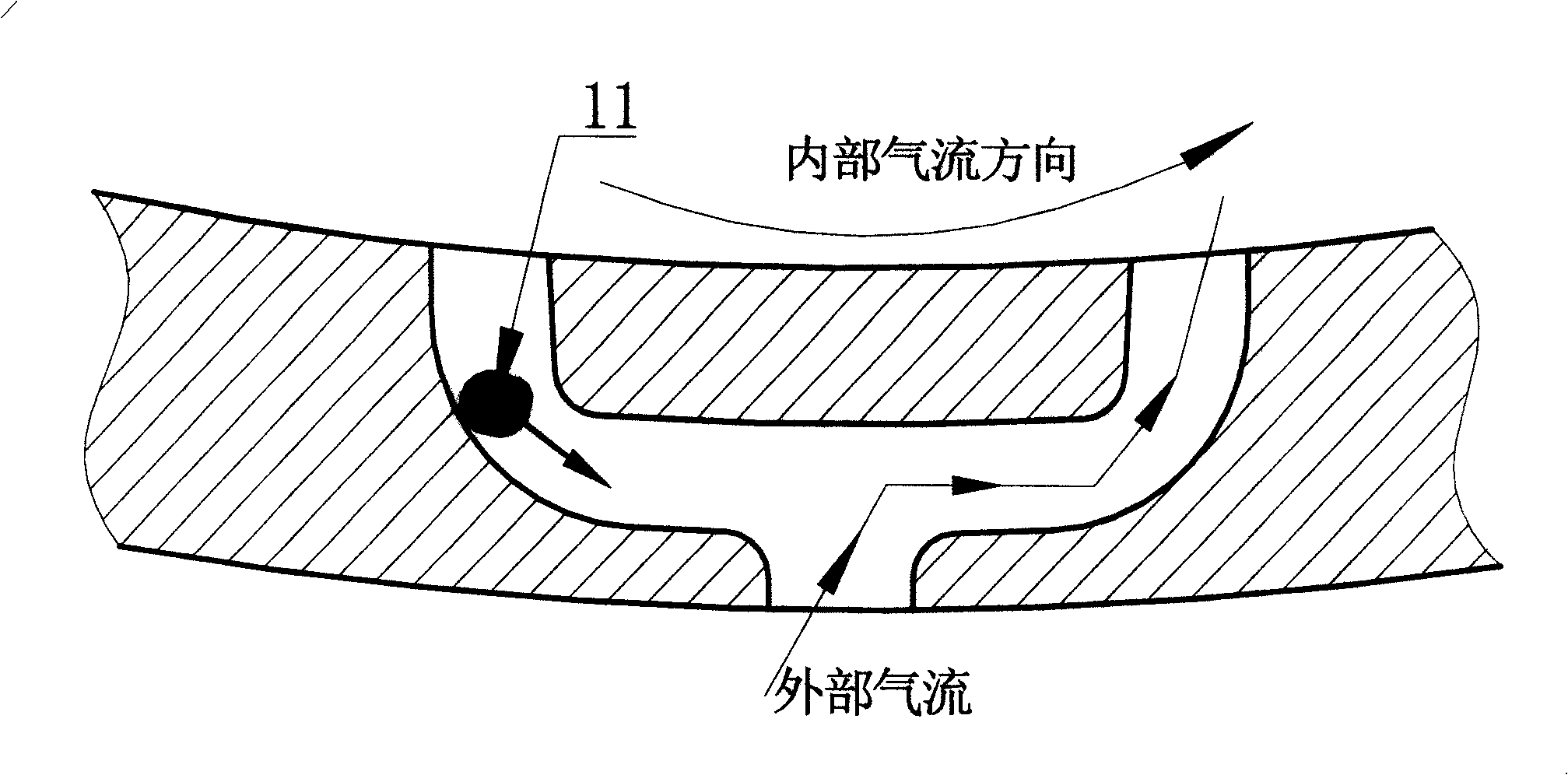

[0028] like Figure 4 As shown, the shape of the hole in this example is "Y" shape. When viewed from the outside of the clutch housing, the hole is located on the outer wall of the clutch housing with only one opening. When viewed from the inside of the clutch housing, the hole is located on the inner wall of the clutch housing with two openings. The left inner channel 31 and the right inner channel 32 are opened on the inner wall 20 of the clutch housing to form a "V" shape, the outer channel 30 is opened on the outer wall 21 of the clutch housing, and one end is connected with the left inner channel 31 and the right inner channel 32 to form a "V" shape. "-shaped bottoms are connected to form a "Y"-shaped channel as a whole. Compared with the current structure with no holes or only simple straight holes on the clutch housing, it can not only discharge the wear debris of the clutch, the water and the lubricating oil infiltrated by the gearbox, but also effectively prevent exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com