Ramp-error compensation circuit for peak current controlled BUCK converter

A technology of peak current control and error compensation, which is applied in the direction of converting DC power input to DC power output, adjusting electrical variables, and controlling/regulating systems. It can solve problems such as output current static errors, eliminate static errors, and ensure accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

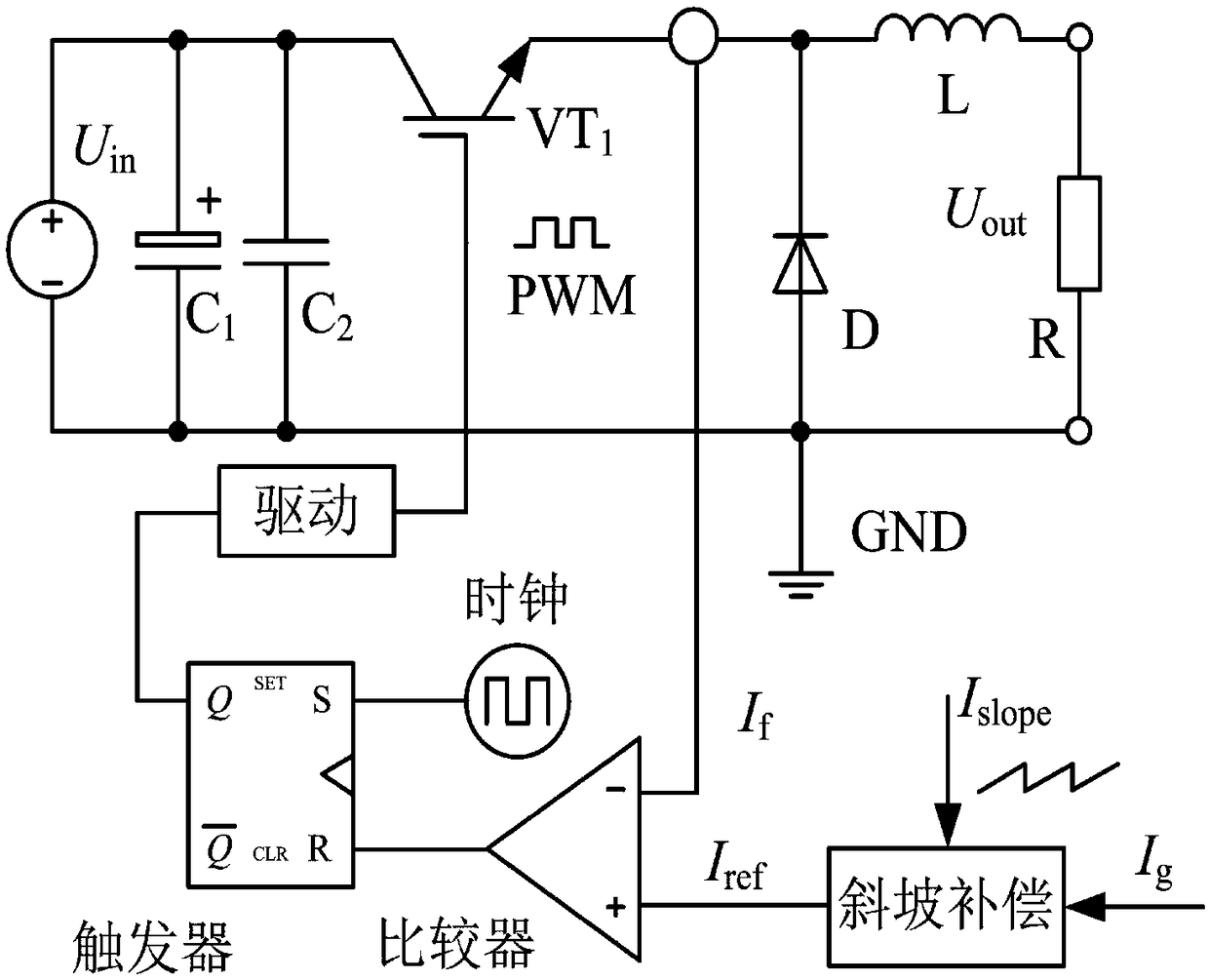

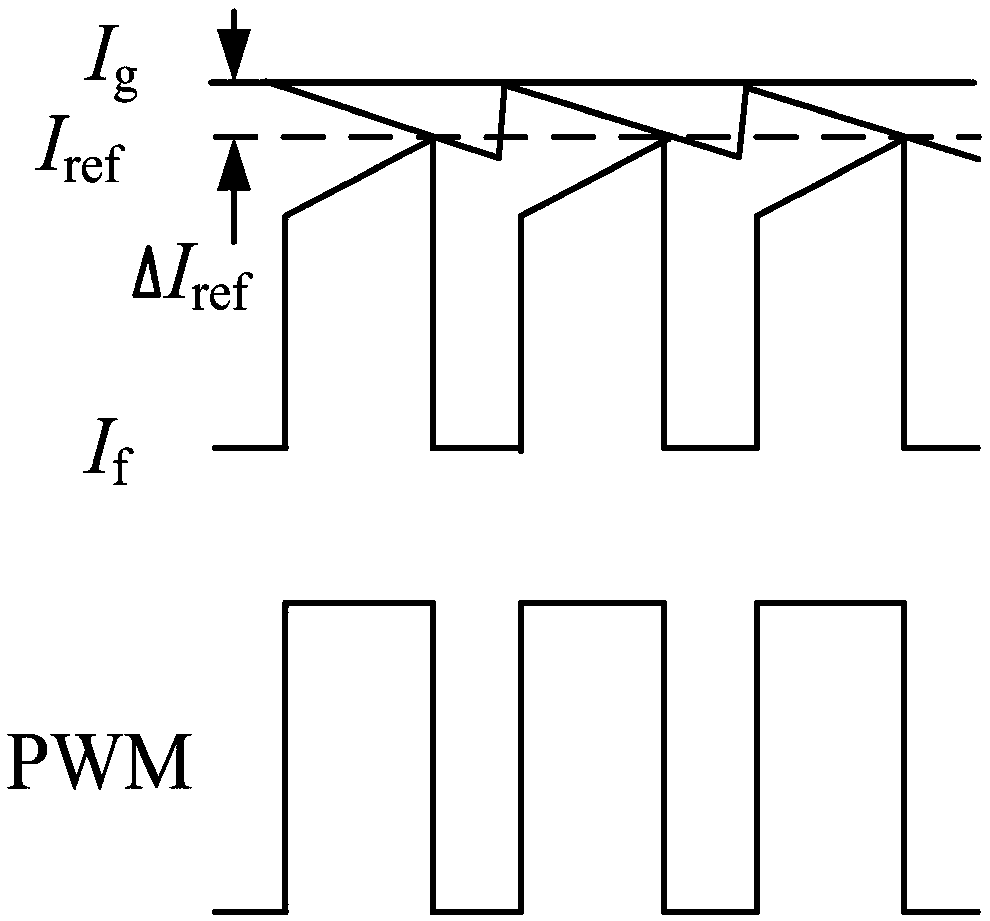

[0059] A specific embodiment of the present invention discloses an error compensation circuit for a peak current control buck converter, the connection relationship of which is as follows Figure 4 shown. The slope-error compensation circuit for the peak current control BUCK converter disclosed in this embodiment includes a slope compensation sub-circuit, an error compensation sub-circuit, and a conditioning amplifier sub-circuit. The slope compensation sub-circuit is connected in parallel with the error compensation sub-circuit, and then connected in series with the conditioning and amplification sub-circuit. A specific connection method is given below.

[0060] Specifically, the slope compensation subcircuit includes an input terminal 1, an input terminal 2, an input terminal 3 and an output terminal. Among them, the input terminal 1 receives the sawtooth wave signal output by the PWM controller, the input terminal 2 receives the bias voltage signal set by the user, the si...

Embodiment 2

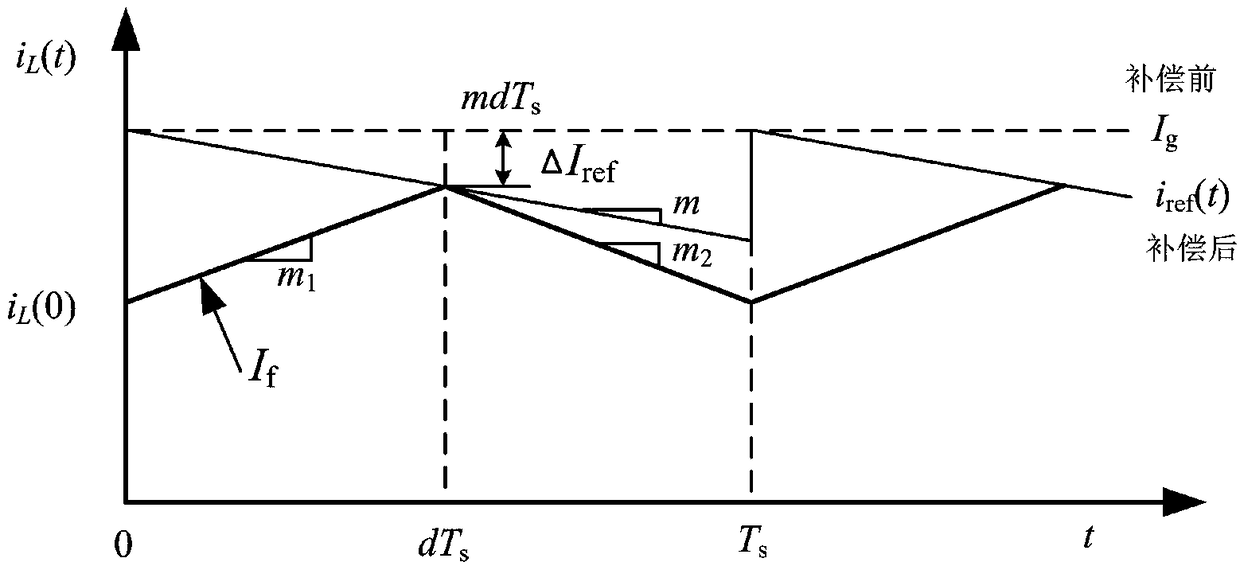

[0067] Optimizing on the basis of the above examples, such as Figure 5 As shown, the slope compensation sub-circuit includes an operational amplifier module 1 and an operational amplifier module 2 connected in series in sequence. The operational amplifier module 1 is used to receive the sawtooth signal and bias voltage signal output by the PWM controller, bias and reverse the sawtooth signal output by the PWM controller, and generate an inverted sawtooth signal that changes from zero and transmit it to Op-amp module 2. The operational amplifier module 2 is configured to receive the above-mentioned inverted sawtooth signal and the current reference signal, and superimpose the inverted sawtooth signal and the current reference signal to generate a current reference signal with slope compensation.

[0068] Preferably, as Figure 6 As shown, the operational amplifier module 1 includes an operational amplifier A1 and resistors R1-R4, and the operational amplifier module 2 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com