Submerged pipeline comprising a jacket comprising a polypropylene block copolymer

A polypropylene block, underwater pipeline technology, used in pipeline systems, pipeline protection, pipeline damage/wear prevention, etc., can solve problems such as loss of sealing function, and achieve good impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

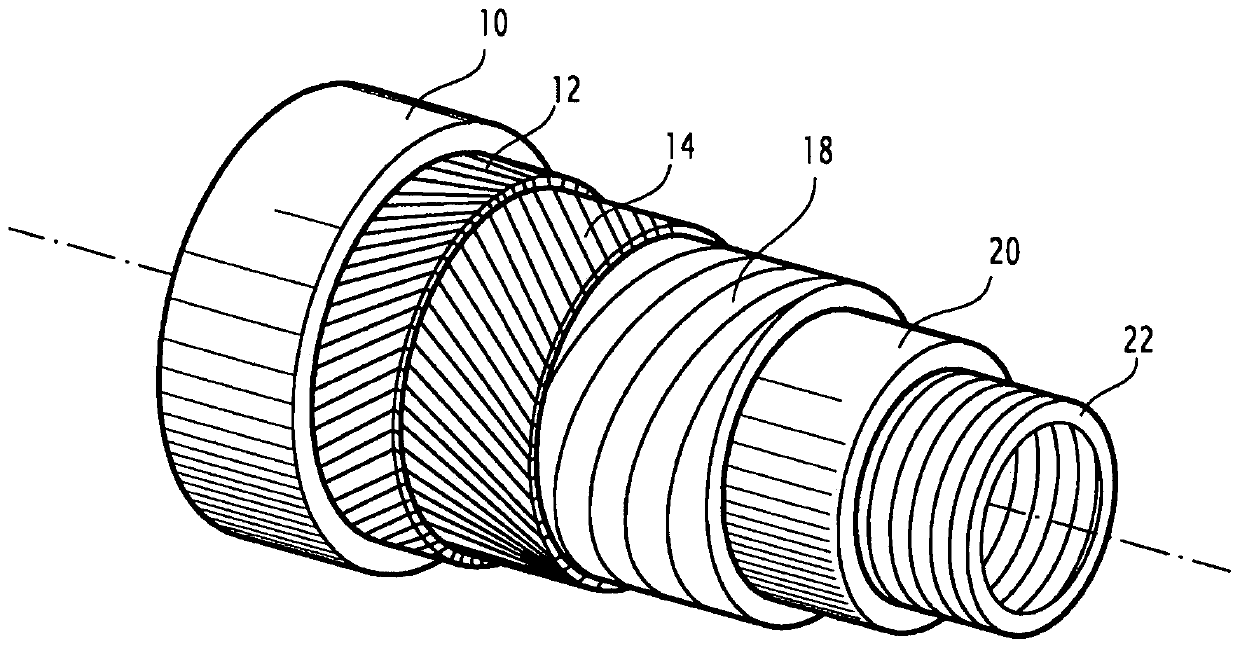

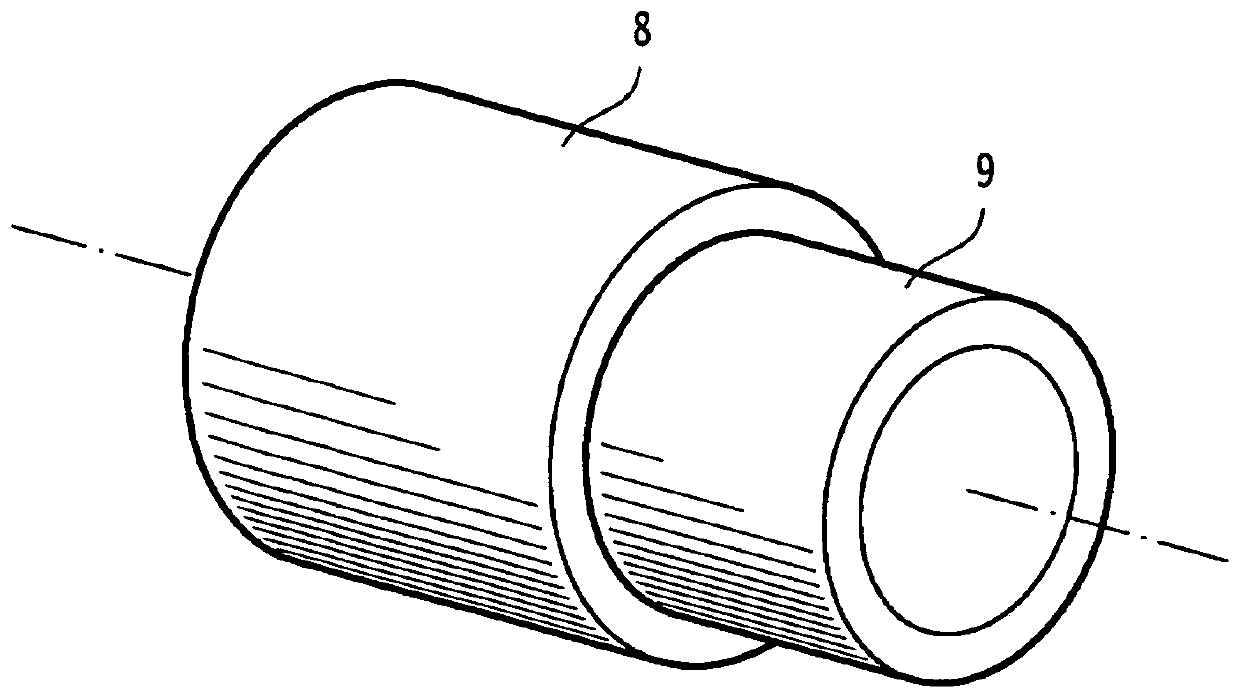

Image

Examples

Embodiment 1

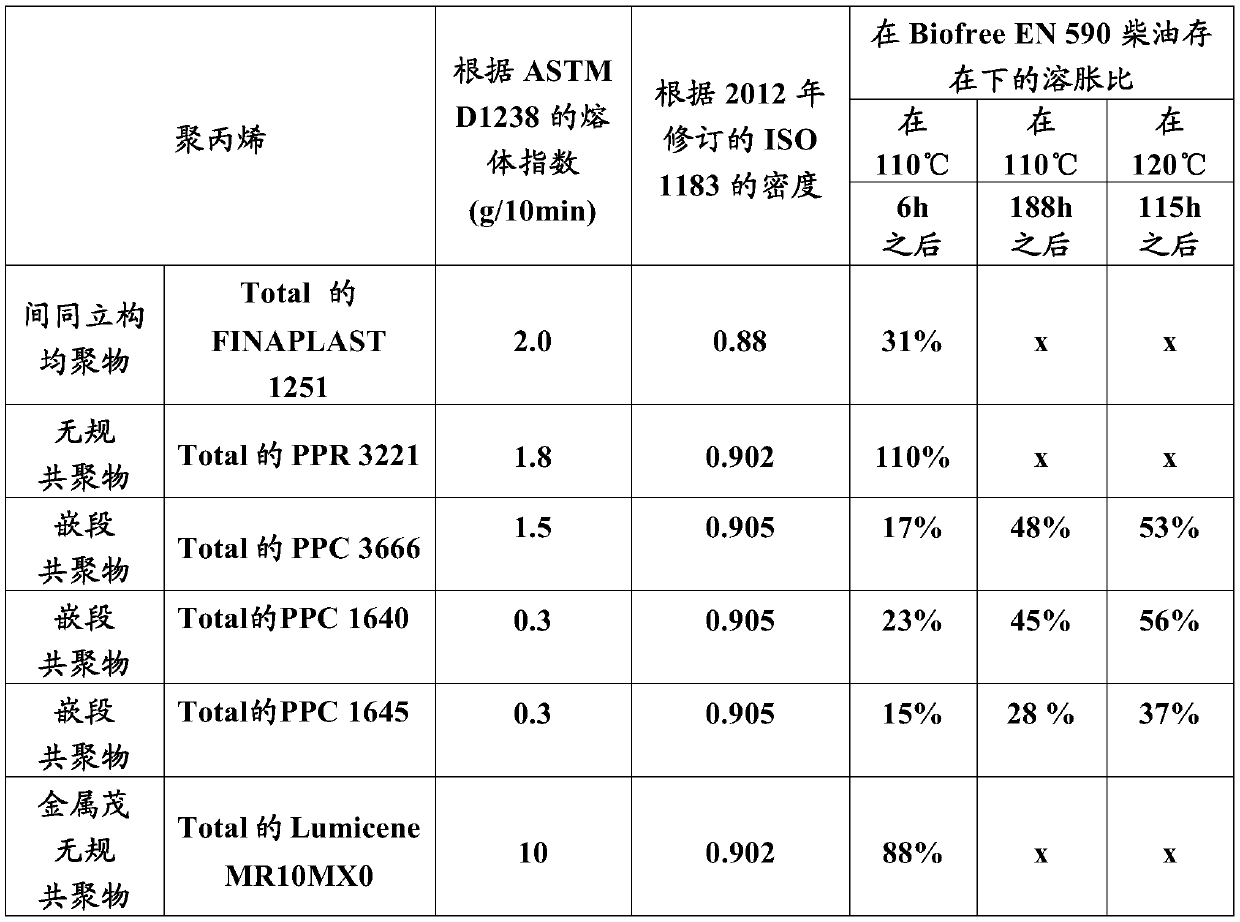

[0164] Example 1: Swelling ratio of polypropylene in the presence of petroleum fluid at elevated temperature

[0165] Samples of different classes of polypropylene were weighed, then contacted with petroleum fluid Biofree EN 590 Diesel, and then weighed after a certain period of time in this fluid. The difference in mass before and after contact enables determination of the degree of swelling.

[0166] Table 1 compares and provides the swelling ratios (mass percent) of different classes of polypropylene in the presence of the petroleum fluid Biofree EN 590 Diesel.

[0167]

[0168] Table 1: Swell ratio of various polypropylenes in the presence of Biofree EN 590 diesel

[0169] These results show that the polypropylene block copolymers used in the sheathing of pipes according to the invention have a low swelling ratio in the presence of hydrocarbons at elevated temperatures.

Embodiment 2

[0170] Example 2: Resistance of polypropylene when severe pressure release

[0171] Several polypropylenes were saturated with gas at high temperature and pressure and then decompressed to atmospheric pressure (1 bar) at a depressurization rate of 70 bar / min similar to flexible pipe operation. The appearance of blisters on the polypropylene surface after this treatment was monitored (Table 2).

[0172]

[0173] Table 2: Occurrence of blistering on various polypropylene surfaces after severe pressure relief

[0174] These results show that the polypropylene block copolymer used in the jacket of the pipe according to the invention is capable of withstanding severe depressurization simulating a production shutdown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com