Tree brushing box, and device adopting same

A technology of brushing and treeing, which is applied to the device, application, and coating of surface coating liquid, which can solve the problems of high labor intensity, low quality of whitening, and unfavorable efficiency, so as to save mortar dust, operate flexibly, and The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention will be further described below in conjunction with description of drawings and specific embodiments:

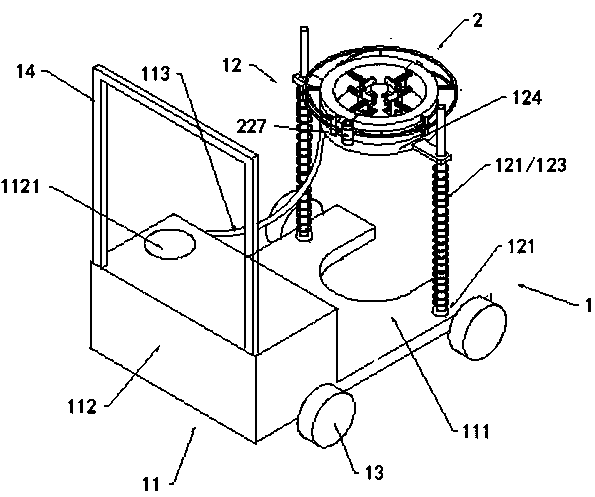

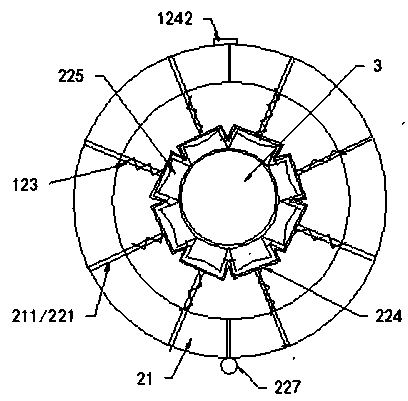

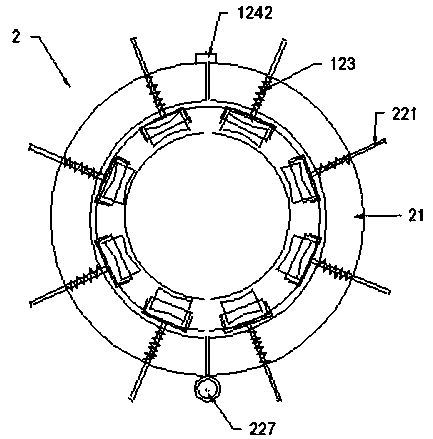

[0028] Such as figure 1 Shown: a spring-supported tree whitening device, including a frame 1 and a brushing box 2.

[0029] 1. Rack.

[0030] Such as figure 1 As shown, the frame 1 includes a base 11 and an elevating mechanism 12. The front end of the base is a notch plate 111, and a notch is arranged in the middle of the front end of the plate. During operation, the tree bar is built into the notch, and the rear end of the base is a pulp bucket 112. The upper end of the slurry bucket is provided with a bucket mouth 1121 for loading slurry, and a conduit 113 is connected between the slurry bucket and the semi-annular box 21 of the brushing box, and the slurry is transported to the semi-annular box 21 by pressurization. The slurry can be drained by the natural drop, the two sides of the base are provided with runners 13, and the rear end of the base is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap