Method for predicting transverse connection morphology of weld beads in wire and arc additive manufacturing

An additive manufacturing and lateral connection technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of unstable accumulation state, high welding bead height, inability to obtain a flat surface, etc., and achieve good lateral connection results. , the effect of good conformity and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention proposes a method for predicting the lateral connection shape of weld beads in arc additive manufacturing. The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

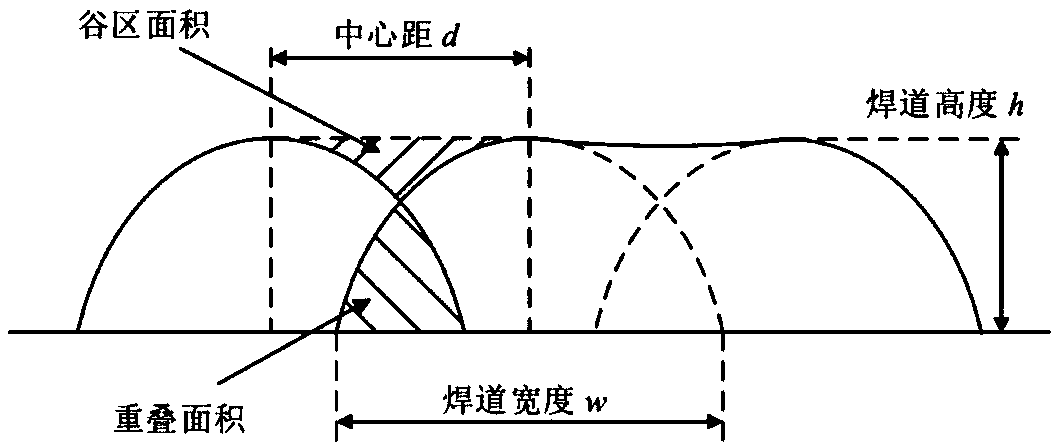

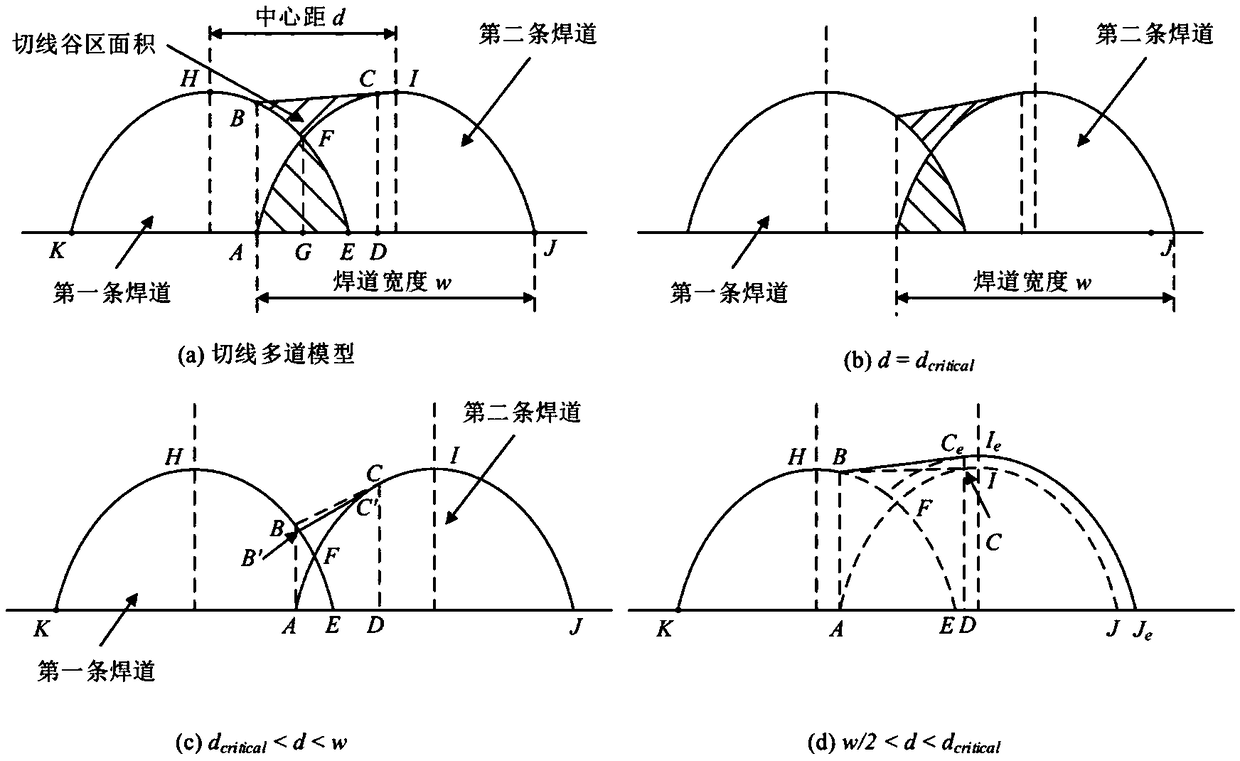

[0025] The present invention proposes a method for predicting the lateral connection morphology of weld beads in arc additive manufacturing, comprising the following steps:

[0026] (1) Determine the parabolic model and its parameters of the single weld bead section.

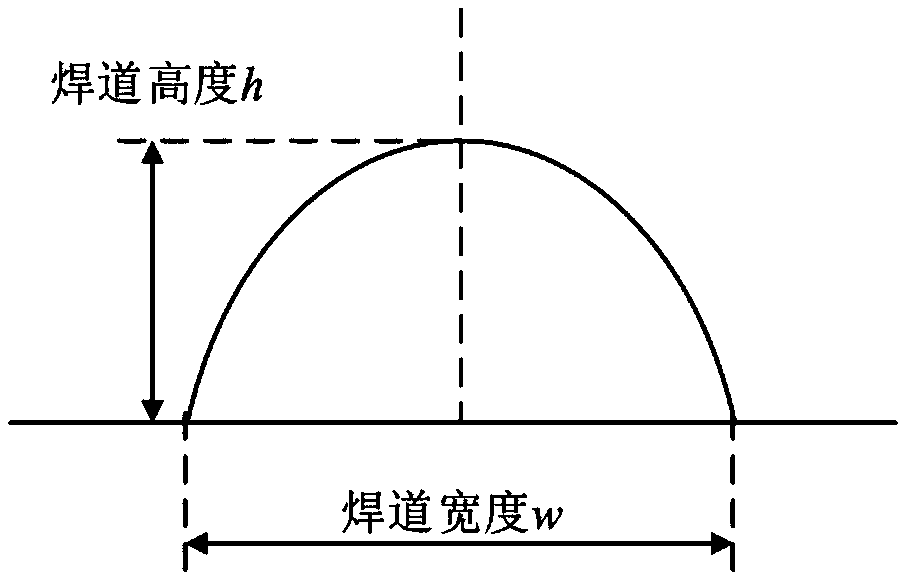

[0027] Weld a single bead on the substrate as the first bead, measure the height h and width w of the first bead;

[0028] In actual operation, according to actual needs, under the selected welding process parameters, a single weld bead is welded on the substrate as the first weld bead, and the N positions of the weld bead (3 places in this embodiment) are respectively measured. For the width and height of the weld bead, the average value of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com