A high-precision and fast positioning device based on the principle of end gear positioning

A technology of positioning device and end tooth disc, applied in positioning devices, chucks, manufacturing tools, etc., can solve the problems of extremely high dimensional accuracy and topographic accuracy, and achieve good repeatability of positioning accuracy, good automatic centering, and accurate maintenance. long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

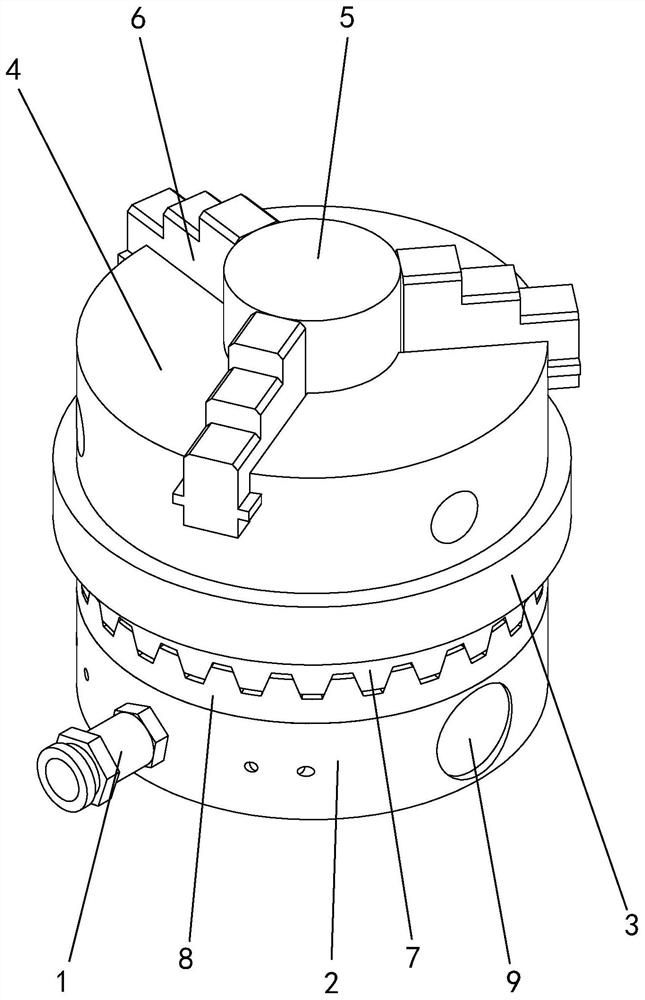

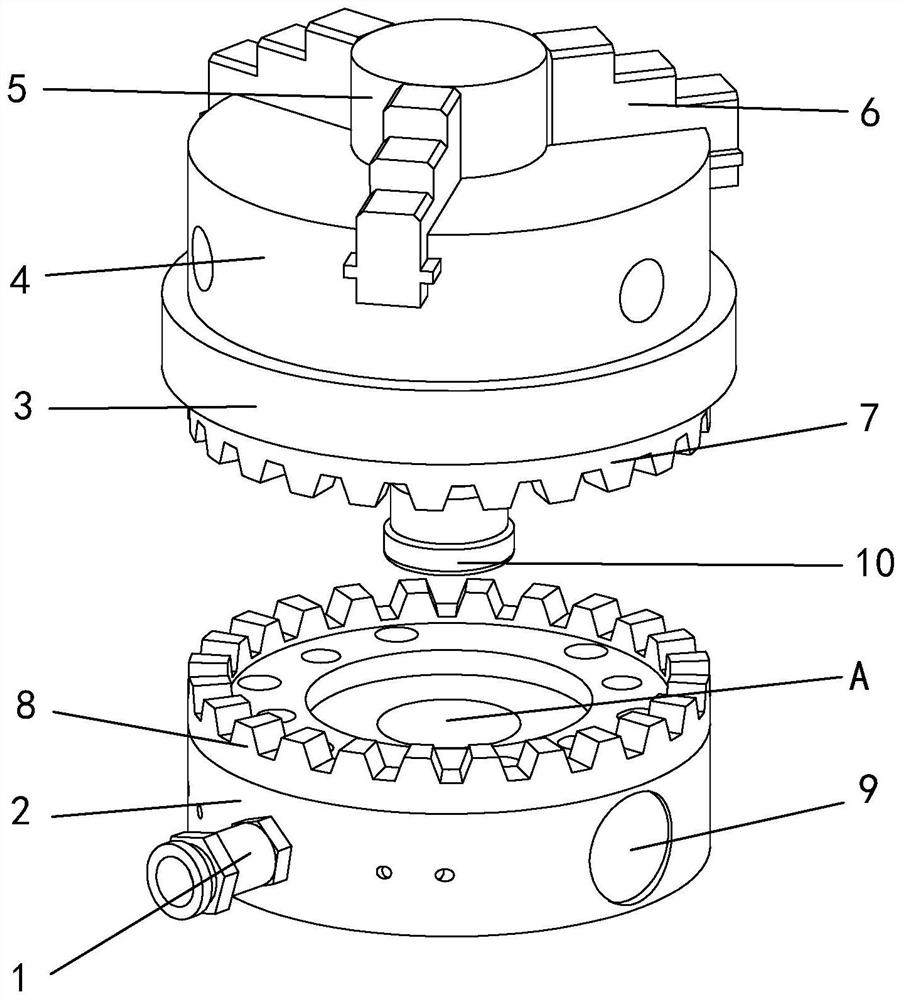

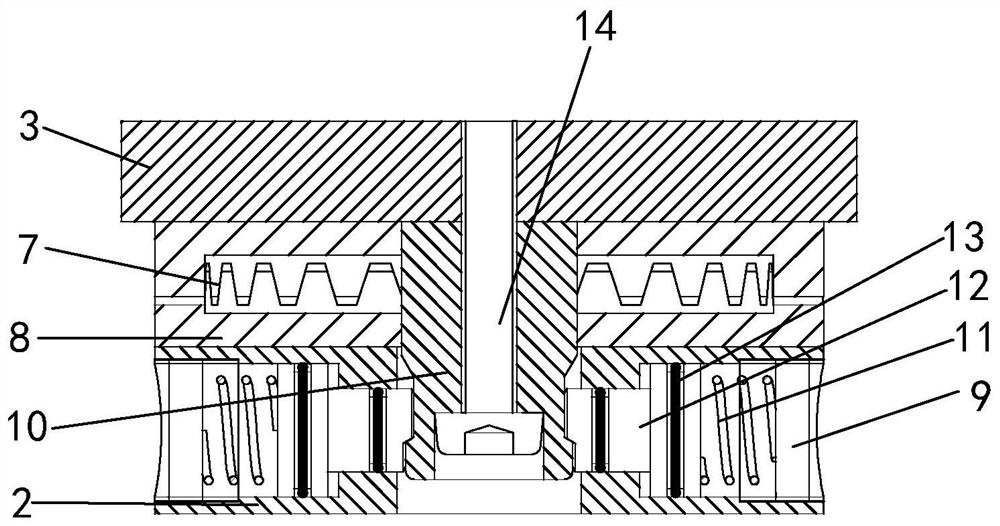

[0015] Specific implementation mode one: as Figure 1 to Figure 8 As shown, the present invention discloses a high-precision rapid positioning device based on the positioning principle of the end tooth disc, including an air joint 1, a columnar base 2, a base plate 3, a three-jaw chuck 4, a joint 10, an end tooth disc and a clamping mechanism, the columnar base 2 is vertically arranged and the middle part of the upper surface is provided with a circular groove A, and the outer peripheral surface of the columnar base 2 is provided with a through hole B and a circular groove C, and the through hole B is connected with the circular groove Groove 1A and round groove 2C are connected to each other, and a clamping mechanism is placed in through hole 1B. The round groove 2C is detachably connected to one end of the gas connector 1 through threads, and the other end of the gas connector 1 Coupled with the high-pressure gas source end joint, the high-pressure gas enters the interior of...

specific Embodiment approach 2

[0016] Specific implementation mode two: as figure 1 , 2 , 4, and 6, this embodiment is a further description of specific embodiment 1, the through hole 1 B and the circular groove 2 C are arranged along the radial direction of the columnar base 2, and the through hole 1 B and the circular groove 2 Groove two C are arranged perpendicular to each other.

specific Embodiment approach 3

[0017] Specific implementation mode three: as Figure 4 As shown, this embodiment is a further description of Embodiment 1 or Embodiment 2. The circular groove 2C communicates with the through hole 1B through the air channel G provided inside the columnar base 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com