An operation method for simulating a slave control device

An operation method and technology for controlling equipment, applied in data exchange network, transportation and packaging, electric vehicle charging technology, etc., can solve problems such as uncontrollable circuit board debugging, complicated operation steps, and single function, so as to improve debugging efficiency and improve Effects of safety and improvement of processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

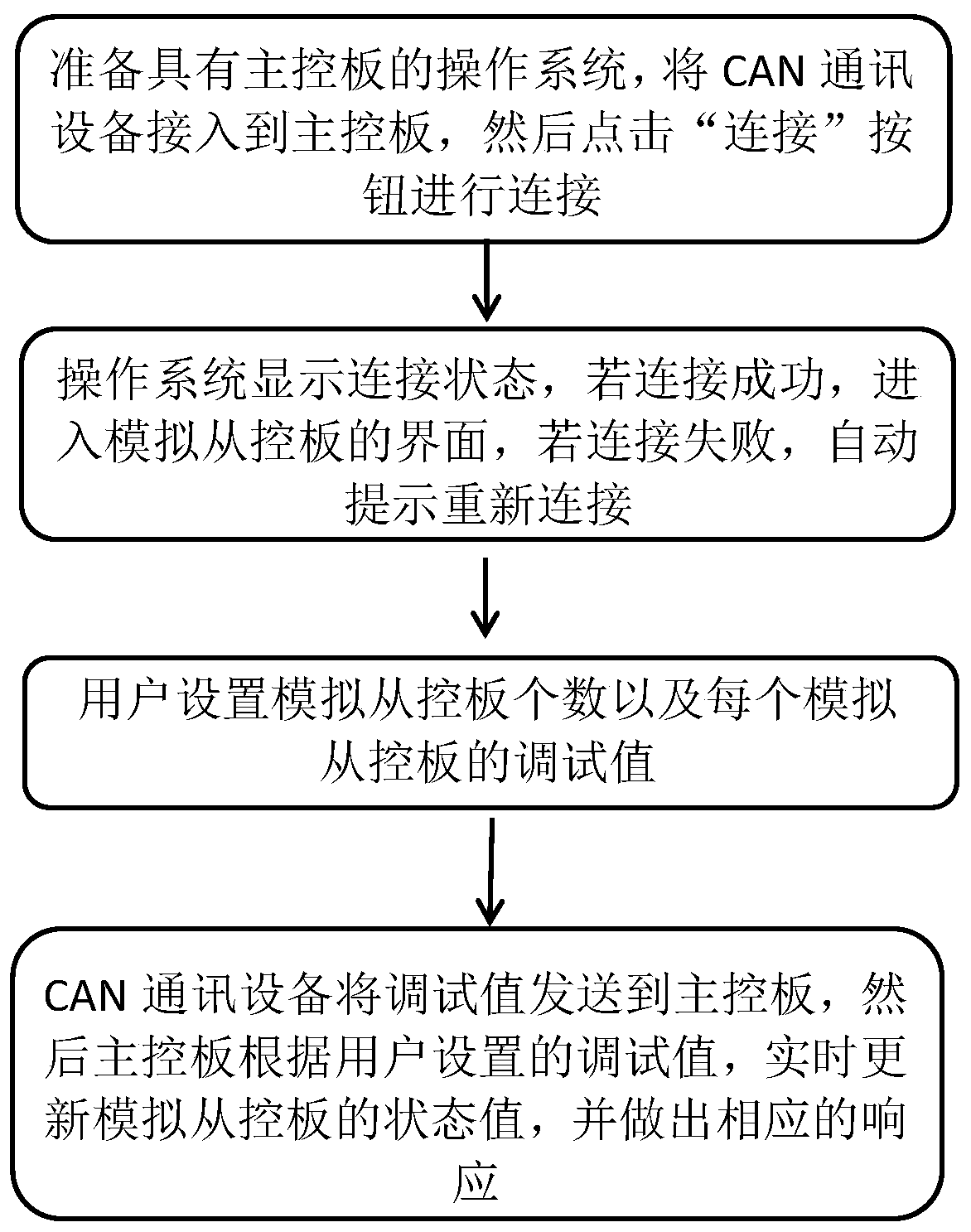

[0028] Such as figure 1 As shown, an operation method for simulating a slave control device includes the following steps:

[0029] 1) Prepare the operating system with the main control board, connect the CAN communication device to the main control board, and then click the "Connect" button to connect;

[0030] 2) The operating system displays the connection status. If the connection is successful, it will enter the interface of the simulated slave control board. If the connection fails, it will automatically prompt to reconnect;

[0031] 3) The user sets the number of simulated slave control boards and the debugging value of each simulated slave control board;

[0032] 4) The CAN communication device sends the debugging value to the main control board, and then the main control board updates the status value of the simulated slave control board in real time according to the debugging value set by the user, and makes a corresponding response.

[0033] It should also be noted...

Embodiment 2

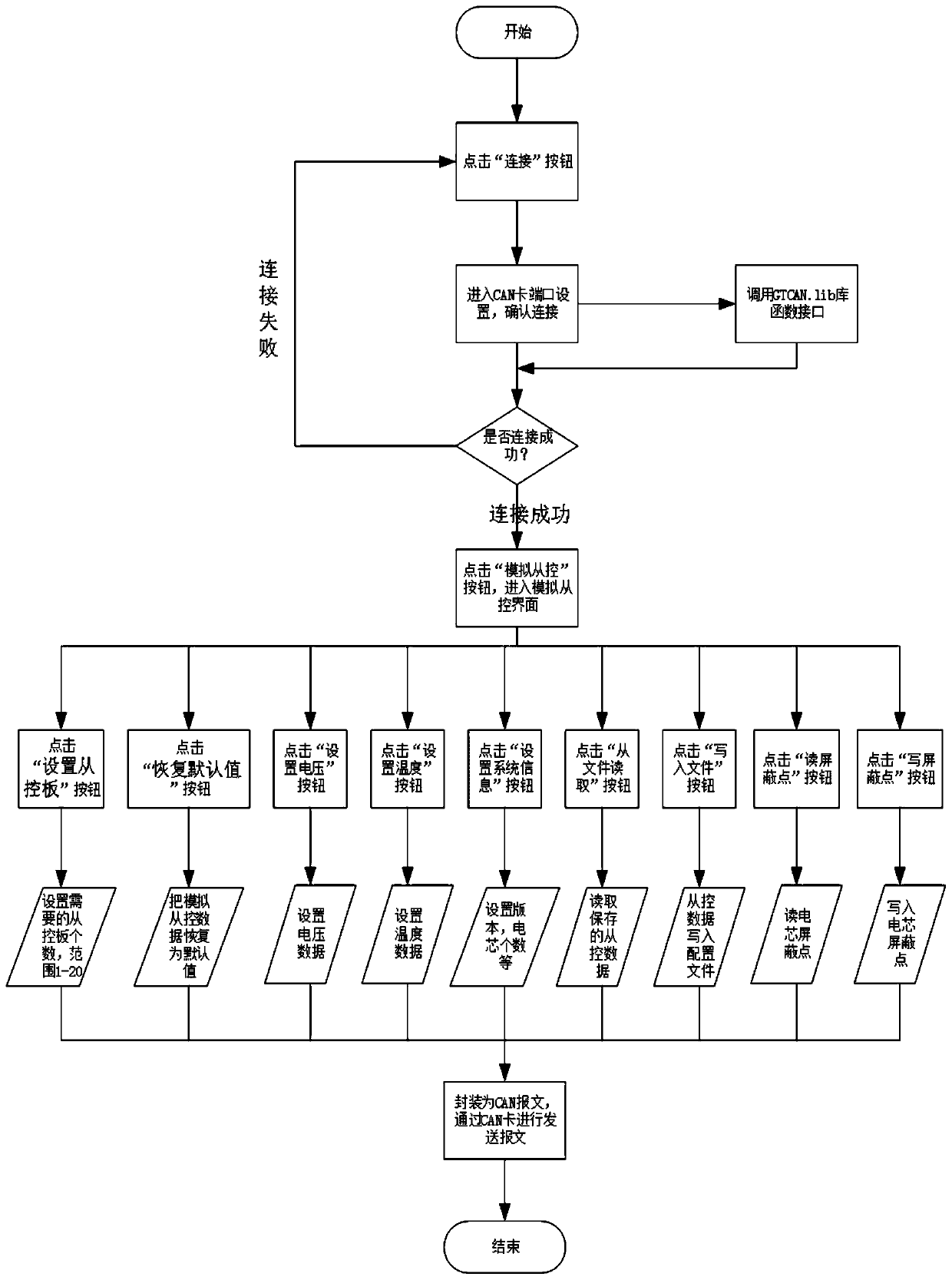

[0042] Such as figure 2 As shown, the difference from Embodiment 1 is that the CAN communication device of this embodiment is a CAN bus, and the debugging value includes the temperature of the analog slave control board, the version number of the analog slave control board, the voltage of the battery cell, the number of battery cells, The number of battery temperature monitoring points, battery factory model, input port, output port and battery shielding point. The CAN bus is connected to the physical bus through the two output terminals CANH and CANL of the CAN transceiver interface chip 82C250, and the state of the CANH terminal can only be high level or suspended state, and the CANL terminal can only be low level or suspended state, and the CAN The node has the function of automatically closing the output in the case of a serious error, so that the operation of other nodes on the bus will not be affected, so as to ensure that the bus will not be in a "deadlock" state due t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com