Lateral box turning-over method for double-layer cigarette box and box turning-over system

A smoke box and box turning technology, which is applied in the directions of lifting devices, emptying containers, loading/unloading, etc., can solve the problem of reducing the efficiency of depalletizing and stacking, the stability and reliability of depalletizing and stacking operations, and reducing the working efficiency and reliability of the turning process Inability to form a continuous production line and other problems, to achieve the effect of reducing equipment maintenance costs, reducing equipment costs, and improving the efficiency of turning boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

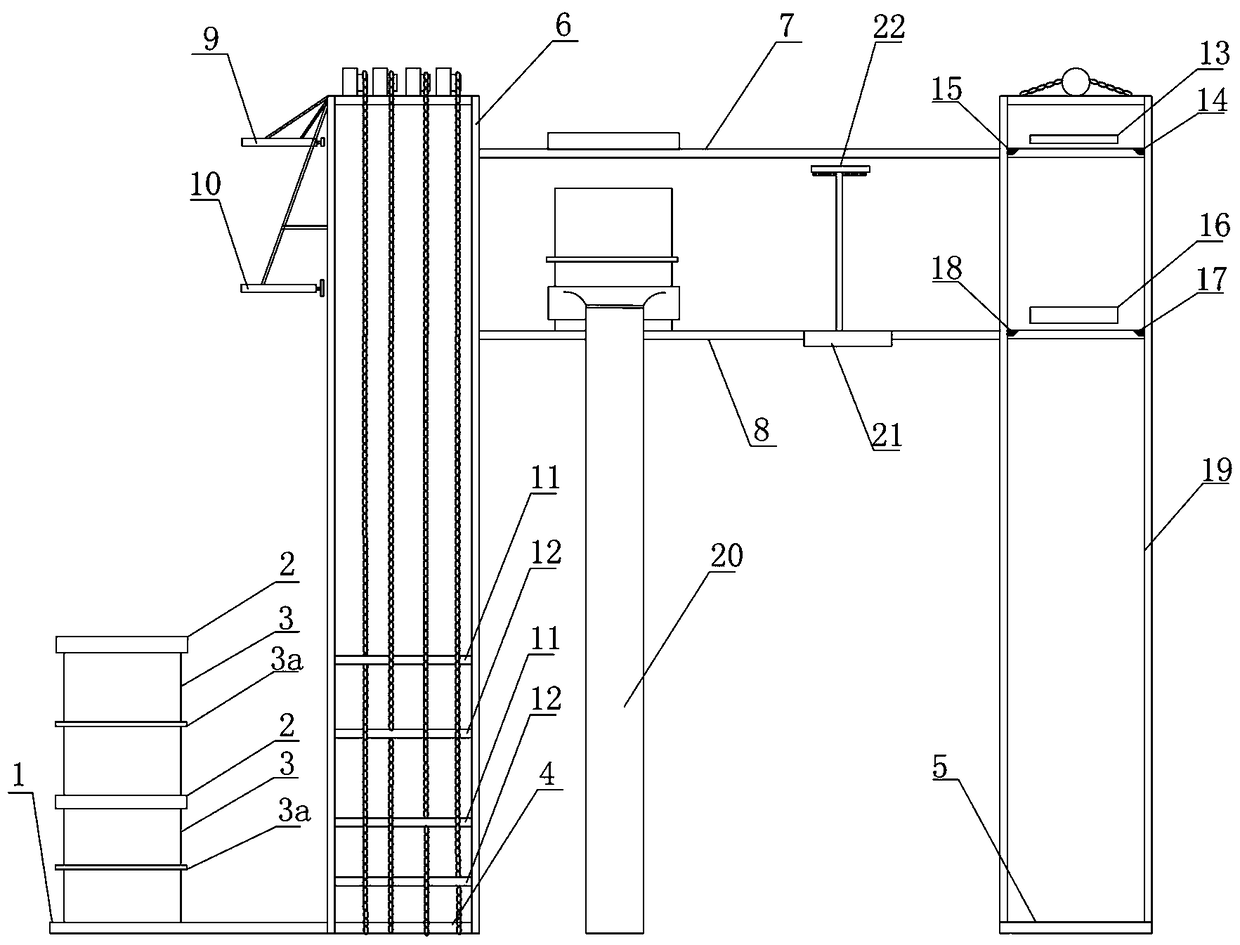

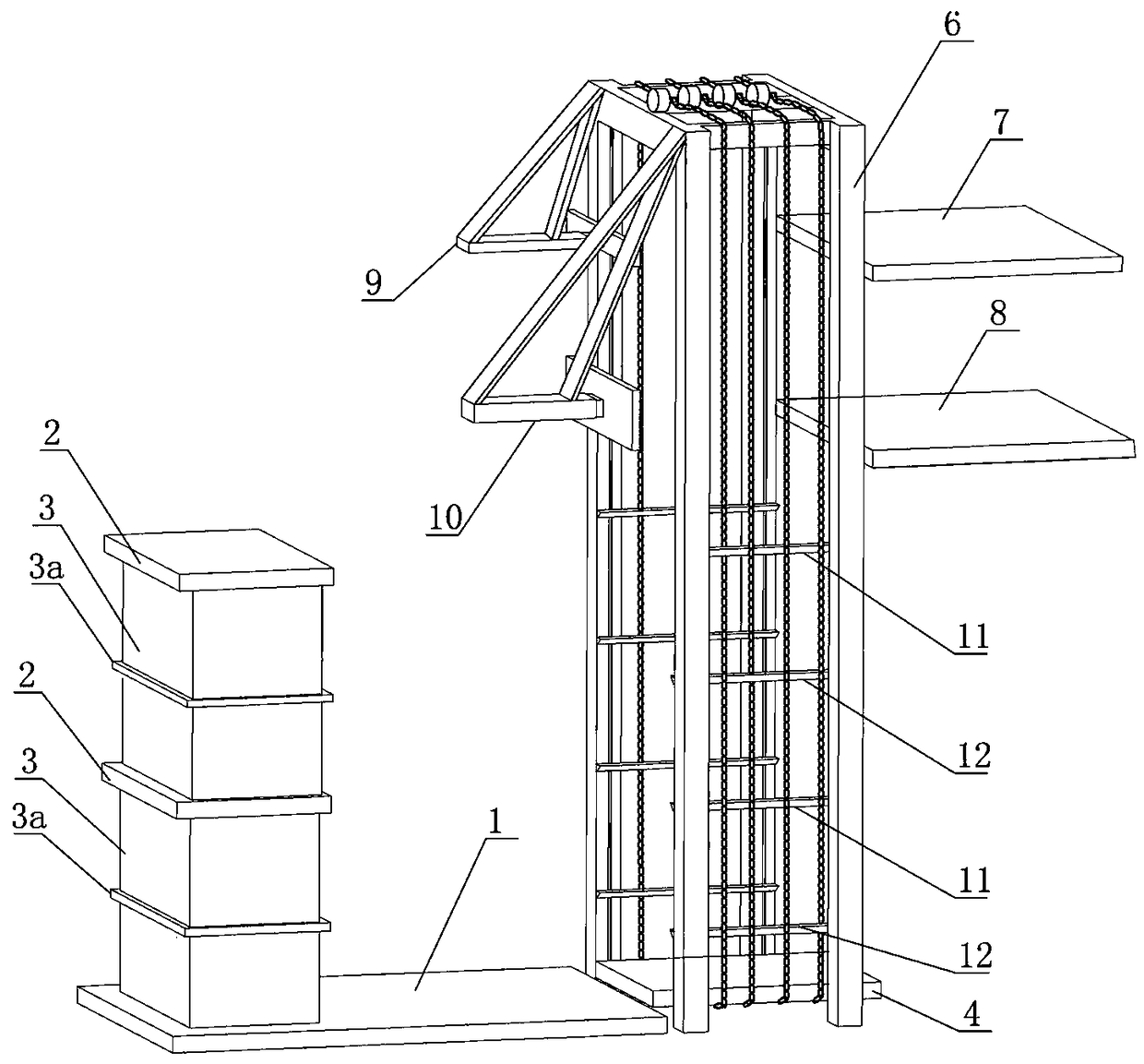

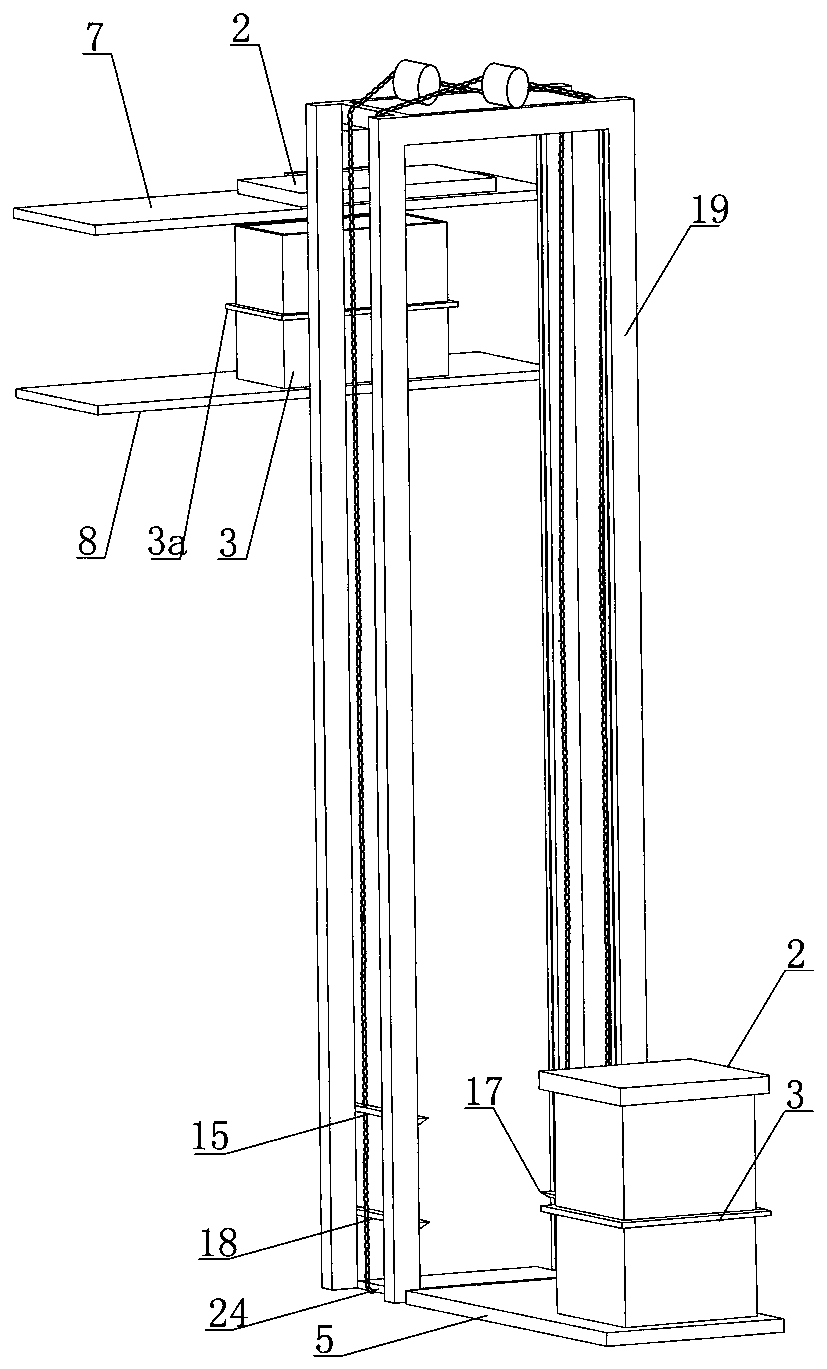

[0047] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

[0048] The invention discloses a side-type overturning method of a double-layer smoke box, which comprises the following steps:

[0049] A. Smoke box transfer: double-layer smoke boxes are transferred from the temporary storage warehouse to the unstacking mechanism; the ambient temperature of the temporary storage warehouse is 20°C-30°C, and the ambient humidity is 50%-70%;

[0050] B. Destacking of cigarette boxes: The smoke boxes are destacked and removed in the destacking mechanism, and the box body 3 after removal of the cover is transported to the downstream turning station through the box conveying track 8, and the removed box cover 2 is transported through the box cover Track 7 is transferred to the downstream palletizing station;

[0051] The specific process is as follows:

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com