A method for controlling the synthesis of nano-nickel phosphide in different phases

A technology of nickel phosphide and nickel chloride hexahydrate, which is applied in the direction of phosphide, nanotechnology, nanotechnology, etc., can solve the problems of easy agglomeration, harsh synthesis conditions, and difficulties, and achieve easy industrial production, low cost, and mild conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

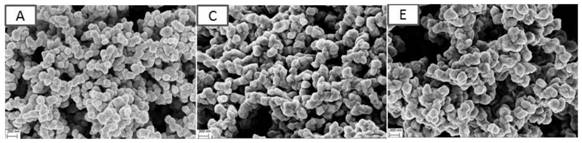

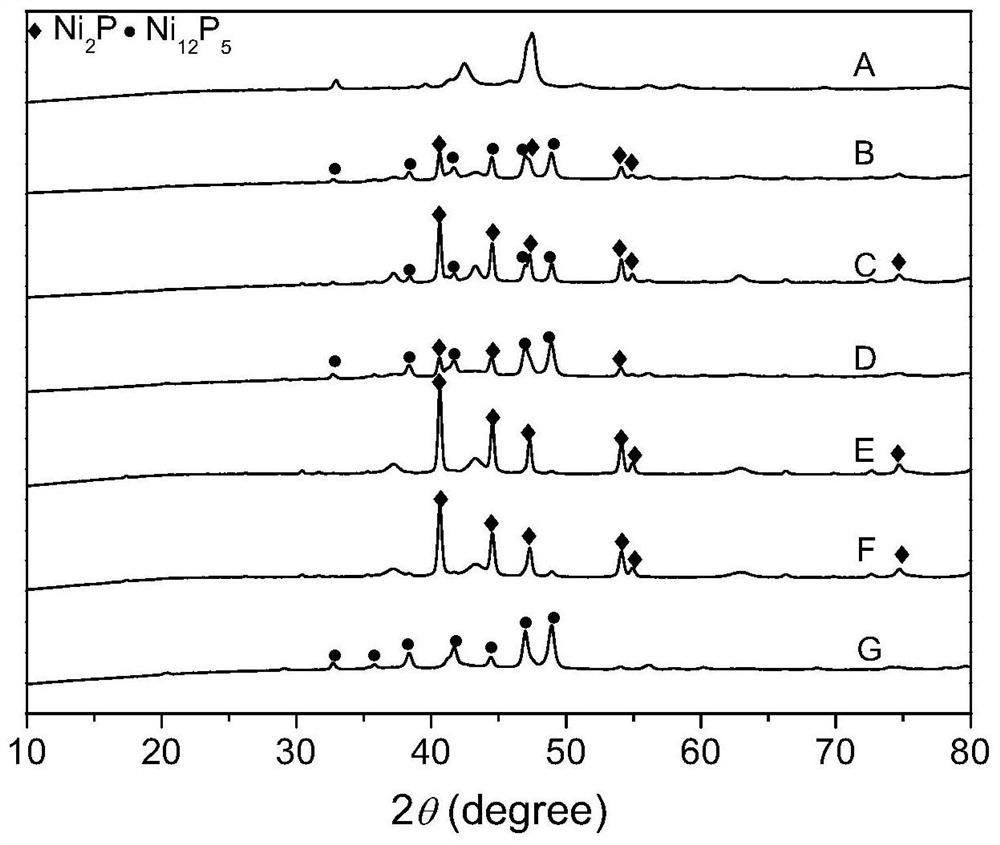

[0016] Weigh 0.2377g of nickel chloride hexahydrate and 0.264g of sodium dihydrogen hypophosphite and dissolve in 20mL of ethylene glycol, pour the resulting solution into a round bottom flask with a reflux device, and treat it in an oil bath at 170°C for 5h , to obtain nickel phosphide intermediate A.

Embodiment 2

[0018] Weigh 0.2377g of nickel chloride hexahydrate and 0.264g of sodium dihydrogen hypophosphite and dissolve in 20mL of ethylene glycol, pour the resulting solution into a round bottom flask with a reflux device, and treat it in an oil bath at 170°C for 5h , to obtain nickel phosphide intermediate. The resulting nickel phosphide intermediate was placed in a tube furnace under N 2 The heat treatment is carried out under the atmosphere. Heat treatment conditions are: N 2 The flow rate is 20mL / min; the heating rate is 2.5°C / min; the temperature is 300°C; the final temperature holding time is 2h. Nano nickel phosphide B was obtained under the above synthesis conditions.

Embodiment 3

[0020] Weigh 0.2377g of nickel chloride hexahydrate and 0.264g of sodium dihydrogen hypophosphite and dissolve in 20mL of ethylene glycol, pour the resulting solution into a round bottom flask with a reflux device, and treat it in an oil bath at 170°C for 5h , to obtain nickel phosphide intermediate. The resulting nickel phosphide intermediate was placed in a tube furnace under N 2 The heat treatment is carried out under the atmosphere. Heat treatment conditions are: N 2 The flow rate is 20mL / min; the heating rate is 2.5°C / min; the temperature is 400°C; the final temperature holding time is 2h. The above synthesis conditions obtain nano-nickel phosphide C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com